Liebherr D834 A7 Diesel Engine Service Repair Manual

$42.00

Manual Included:

- Service Repair Manual: 402 Pages

Specifications:

- Brand: Liebherr

- Model: D834 A7

- Type: Diesel Engine

- Manuals: Service Repair Manual

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content (D834 A7 – Repair Manual)

Title

Repair instruction

Foreword / Imprint

Introduction

Explanation of symbols

Warnings

Tips and Recommendations

General Information

INH

Introduction

Regulations for avoiding health and environmental risks

Emergency drive program for engines with electronic control units

Installation information

Installation of screws and nuts

Engine Presentation

Explanation of type plate

Explanation of model designation

Specifications

D834 A7

Engine Description

Engine description

Cooling System Overview

Cooling system

Coolant Manifold

Additional work

Important information

Thermostat

Technical data

Important information

Remove coolant lines

Remove coolant outlet pipe

Remove thermostat

Remove thermostat housing

Install thermostat housing

Install thermostat

Install coolant outlet pipe

Install coolant lines (thermostat housing)

Mount coolant lines

Coolant Pump

Technical data

Important information

Remove V-ribbed belt

Remove coolant lines

Remove V-ribbed belt pulley

Remove coolant pump

Mount V-ribbed belt

Install coolant lines (to air compressor / engine)

Install V-ribbed belt

Coolant Pump – Overhaul

Additional work

Technical data

Important information

Special tools

Determine impeller installation dimension

Measure installed dimension

Remove coolant pump hub

Remove retaining ring

Remove impeller

Remove rotary seal

Install bearing

Install retaining ring

Press-fit hub, coolant pump

Install rotary seal

Check installed dimension

Hydraulic press-fitting of impeller

Check dimension, impeller to coolant pump housing

Mounted Aggregates – Overview

Mounted aggregate

Power Take-off

Additional work

Technical data

Important information

V-ribbed belt pulley, remove

Remove power take-off

Install power take-off

Mount V-ribbed belt

Air Compressor

Additional work

Technical data

Important information

Special tools

Remove air compressor suction line

Remove vent line for engine venting

Dismount oil return line

Remove bracket (holder)

Remove coolant lines

Remove heat shield, exhaust manifold (cyl. 3 and 4)

Swing away oil separator

Remove heat shield, exhaust manifold

Dismount exhaust manifold

Remove formed oil return pipe (air compressor)

Remove air compressor

Install air compressor

Install exhaust manifold / heat shield / oil separator back

Install coolant lines and vent lines

Air Compressor – Overhaul

Additional work

Technical data

Important information

Special tools

Remove compressor connections

Install disassembly tool on compressor

Dismount drive gear

Mount drive gear

Remove tool

Reconnect compressor

Belt Drive – Alternator

Technical data

Remove alternator V-ribbed belt

Remove coolant-compressor belt tensioner

Install coolant-compressor belt tensioner

Install alternator V-ribbed belt

Belt Drive – Kaemiko-AB

Technical data

Important information

Special tools

Install engine cranking device

Remove V-ribbed belt

Remove deflection pulley

Install deflection pulley

Install V-ribbed belt

Remove assembly tool

Remove engine cranking device

Belt Drive – Kaemiko-C

Important information

Special tools

Install engine cranking device

Remove V-ribbed belt (coolant compressor)

Remove deflection pulley

Install deflection pulley

Install V-ribbed belt (coolant compressor)

Remove assembly tool

Remove engine cranking device

Alternator (Generator)

Additional work

Technical data

Important information

Special tools

Disconnect alternator electrical connections

Remove alternator

Remove support / carrier

Remove V-ribbed belt pulley

Install V-ribbed belt pulley

Tighten fixing nut

Install support and retainer

Install alternator

Connect electrical connections

Starter

Technical data

Important information

Special tools

Remove starter

Install starter

Refrigerant / A/C Compressor

Additional work

Technical data

Important information

Special tools

Close coolant connections

Remove A/C compressor

Remove A/C compressor bracket

Install A/C compressor and remove sealing plugs

CRS – Common Rail System (Overview)

Injectors and Pressure Pipe

Remove / install injectors and pressure pipe

Technical data

Important information

Special tools

Remove high-pressure lines and pressure pipe

Remove rail pressure sensor and pressure limiting valve

Install injectors and pressure pipe

High-pressure Pump

Remove / install high-pressure pump

Technical data

Important information

Special tools

Remove high-pressure pump

Adapt drive gear, high-pressure pump

Install high-pressure pump

Connect fuel and high-pressure lines

Flame Start System

Remove / install flame start system

Technical data

Important information

Special tools

Remove flame glow plug and solenoid valve

Install flame start system and fuel line

Charging (Turbocharging)

General information on charging

Charge-air Pipes

Remove / install charge-air pipes

Additional work

Technical data

Important information

Remove charge-air manifold (compressor side)

Remove charge-air inlet housing

Remove charge-air manifold

Remove charge-pressure sensor

Install charge-pressure sensor

Install charge-air pipes and manifolds

Exhaust Turbocharger

Exhaust turbocharger – remove / install

Technical data

Important information

Special tools

Remove charge-air pipe

Remove engine-vent line

Remove oil return line

Remove holders and coolant lines

Remove heat shields and exhaust manifold

Remove intake neck

Remove exhaust turbocharger

Install exhaust turbocharger and timing valve

Connect wastegate control hose

Install exhaust manifold and heat shields

Fill turbocharger with oil

Install coolant and oil lines

Install charge-air pipe

Intake / Exhaust System

System overview

Air Distribution Pipe

Remove / install air distribution pipe

Additional work

Technical data

Important information

Special tools

Remove charge-air manifold (compressor side)

Remove charge-air inlet housing

Remove fuel line (high-pressure pump ↔ air distribution pipe)

Remove high-pressure line (HP pump ↔ pressure pipe)

Remove high-pressure lines (cyl. 1–4)

Remove pressure pipe

Remove temperature sensor

Remove air distribution pipe

Install air distribution pipe and all removed lines / sensors

EGR Module

EGR module – remove / install

Additional work

Technical data

Important information

Remove coolant lines and temperature sensor

Remove EGR module and EGR closing flap

Install EGR module, EGR flap, coolant lines, sensor, and lifting eye

Exhaust Manifold

Exhaust manifold – remove / install

Additional work

Technical data

Important information

Special tools

Remove heat shield, oil separator, vent line

Remove exhaust manifold

Install exhaust manifold and refit removed parts

Cylinder Head (Overview)

Rocker Arm Gear (Kipphebelwerk)

Remove / install rocker arm gear

Additional work

Technical data

Important information

Remove cylinder head cover

Remove rocker arm shaft / gear

Install rocker arm gear

Install cylinder head cover

Rocker Arm Gear – Overhaul

Additional work

Technical data

Important information

Special tools

Disassemble rocker arm gear

Assemble rocker arm gear

Cylinder Head – Remove / Install

Additional work

Technical data

Important information

Special tools

Remove valve bridges and push rods

Loosen cylinder head bolts in sequence

Remove cylinder head and gasket

Install new gasket and cylinder head

Tightening sequence and tightening torques

Install valve bridges and push rods

Valve Clearance

Check / adjust valve clearance

Technical data

Important information

Special tools

Install engine cranking device

Set engine to adjustment position

Check / adjust inlet valve

Check / adjust exhaust valve

Install cylinder head cover

Remove cranking device

Valve Stem Seals

Remove / install valve stem seals

Additional work

Technical data

Important information

Special tools

Set engine to TDC

Remove valve springs and keepers with special tool

Remove valve stem seals

Install valve stem seals and springs

Refit valve bridges and push rods

Remove cranking device

Valve Drive

General description of valve train

Camshaft

Remove / install camshaft

Additional work

Technical data

Important information

Special tools

Remove flange and install puller

Remove camshaft and tappets

Install tappets and camshaft

Check camshaft end float

Install camshaft gear

Camshaft Bearings

Remove / install camshaft bearings

Additional work

Important information

Special tools

Removal sequence for camshaft bearings

Use centering discs in bearing seats

Install camshaft bearings in correct order

Check oil bores

Timing Gears – Overview

Timing Gears – Remove / Install

Additional work

Technical data

Special tools

Remove intermediate gears

Fix crankshaft gear

Install engine cranking device

Align timing marks

Remove / install oil-pump drive gear

Remove / install camshaft gear

Remove / install crankshaft gear

Recheck overlap marking and remove cranking device

Engine Lubrication (Overview)

Oil Cooler

Remove / install oil cooler

Technical data

Important information

Drain coolant

Remove oil cooler housing and cooler

Install oil cooler and housing

Install locking screw

Oil Pan

Remove / install oil pan

Technical data

Consumables

Important information

Special tools

Remove oil return line and formed oil return pipe

Remove lower oil pan

Remove oil suction pipe, dipstick, filler pipe

Remove upper oil pan

Install upper and lower oil pan

Refit oil return line and formed pipe

Oil Pump

Remove / install oil pump

Additional work

Technical data

Important information

Special tools

Unscrew oil-pump fixing screws

Remove oil pump

Check gearwheel axial play

Disassemble / assemble oil pump

Install oil pump and tighten screws

Oil Injection Nozzles

Remove / install oil spray nozzles

Additional work

Technical data

Important information

Special tools

Remove oil spray nozzles

Install oil spray nozzles and align

Crank Drive

General description of crank drive

Vibration Damper

Remove / install vibration damper

Additional work

Technical data

Important information

Special tools

Install engine cranking device

Remove V-ribbed belt pulley

Loosen and remove vibration damper

Install and tighten vibration damper

Install V-ribbed belt pulley

Remove cranking device

Flywheel

Remove / install flywheel

Technical data

Important information

Special tools

Remove flywheel with guide mandrel

Check flywheel run-out

Install flywheel and tighten screws in sequence

Remove / install starter ring gear

Piston and Connecting Rod

Remove / install piston with conrod

Additional work

Technical data

Important information

Special tools

Remove conrod bearing cap

Remove piston and pin

Check piston rings, ring end gap, pin bore, and conrod bore

Install rings, pin, piston, and bearing cap

Check piston protrusion

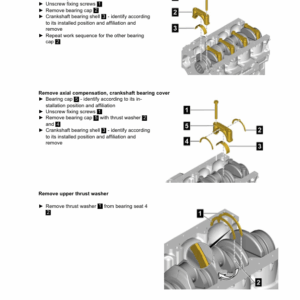

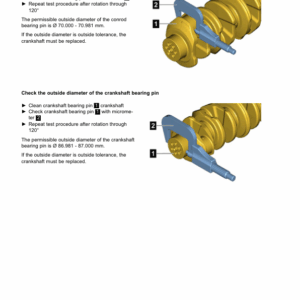

Crankshaft

Remove / install crankshaft

Additional work

Technical data

Important information

Special tools

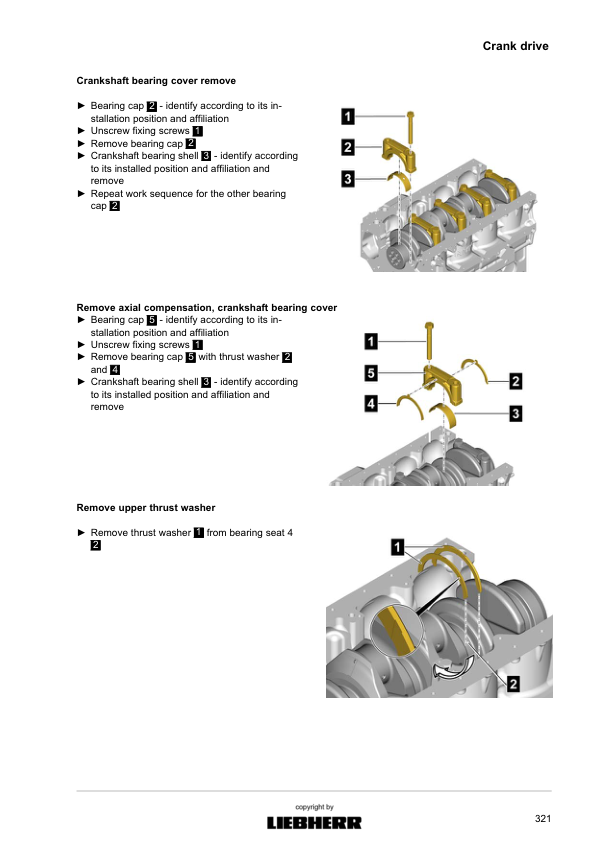

Remove bearing caps and thrust washers

Remove crankshaft

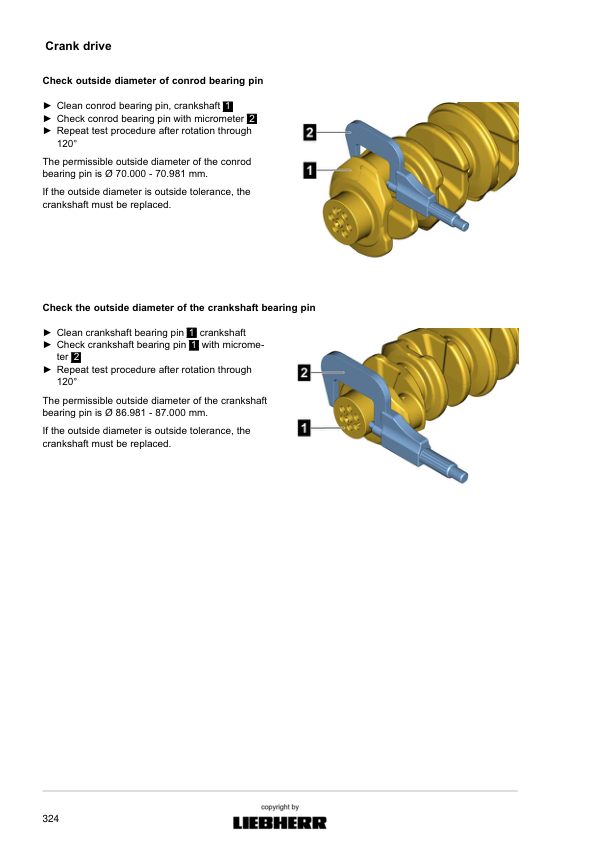

Inspect crankshaft and bearings

Install crankshaft, thrust washers, and caps

Tighten bearing cap screws

Check crankshaft end play

Crankshaft Sealing Rings – Front

Remove / install front crankshaft seal

Additional work

Important information

Special tools

Remove seal with special tool

Press in new seal to specified position

Crankshaft Sealing Rings – Rear

Remove / install rear crankshaft seal

Additional work

Important information

Special tools

Remove seal with special tool

Press in new seal to specified position

Crankcase

Crankcase – remove / install components

Crankcase Ventilation

Remove / install crankcase breather

Additional work

Important information

Special tools

Remove oil-air separator

Remove vent line and oil return in oil pan

Install all components in reverse order

Flywheel Housing

Remove / install flywheel housing

Additional work

Important information

Remove lifting eye

Remove housing

Install housing and lifting eye

Timing Case Cover

Remove / install timing case cover

Additional work

Technical data

Important information

Special tools

Remove cover and seal

Install new seal and cover

Timing Case

Remove / install timing case

Additional work

Important information

Remove lower fixing screws

Remove timing case and seal

Install timing case and tighten lower screws

Technical Data

Tightening torques

Locking screws

Cooling system data

Mounted aggregates

Common rail system data

Charging data

Intake / exhaust system data

Cylinder head data

Timing gear data

Engine lubrication data

Crank drive data

Conrod and piston data

Crankcase data

Assembly tightening torques

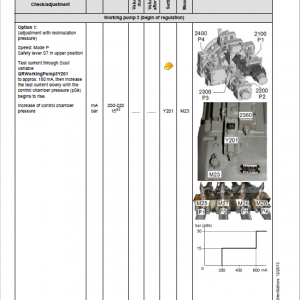

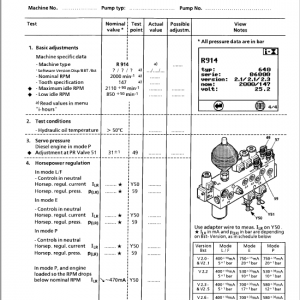

Test and setting values

Special Tools – Overview

Special tools

Special tools with order number

Lifting devices

Engine stand and expansions

Be the first to review “Liebherr D834 A7 Diesel Engine Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.