Liebherr A311 Litronic Excavator Operators Service Repair Manual

Price range: $40.00 through $45.00

Manual Included:

PIN/Type – 718

- Service Repair Manual: 2661 pages

- Operators Manual: 217 pages

PIN/Type – 1036

- Service Repair Manual: 3323 pages

- Operators Manual: 258 pages

Specifications:

- Type: Excavator

- Model: A311

- PIN/Type: 718 & 1036

- Manuals: Operators Manual, Repair Manual

- Language: English

- Format: PDF

- Description

- Additional information

- Reviews (0)

Description

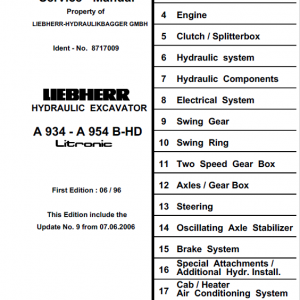

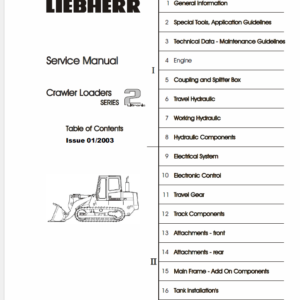

Table of Content – Liebherr Service Repair Manual – A 311

- Book I Chapter 1-7 (Page 1)

- Identification (Page 1)

- Introduction (Page 3)

- Main group directory (Page 5)

- Book II Chapter 8 (Page -1)

- Identification (Page 7)

- Main group directory (Page 9)

- Book III Chapter 9-19 (Page -1)

- Identification (Page 11)

- Main group directory (Page 13)

- 1. General Information (Page 32)

- 1.02 Modification of series (Page 17)

- 1.10 Safety instructions (Page 19)

- 1.20 Tightening torques (WN 4037 I) (Page 33)

- 1.21 Tightening torquex for screw connections (Page 39)

- 1.22 Assembly instruction for hydraulic cylinder (WN 4121B) (Page 43)

- 1.24 Assembly instruction for hydraulic cylinder (WN 4122B) (Page 49)

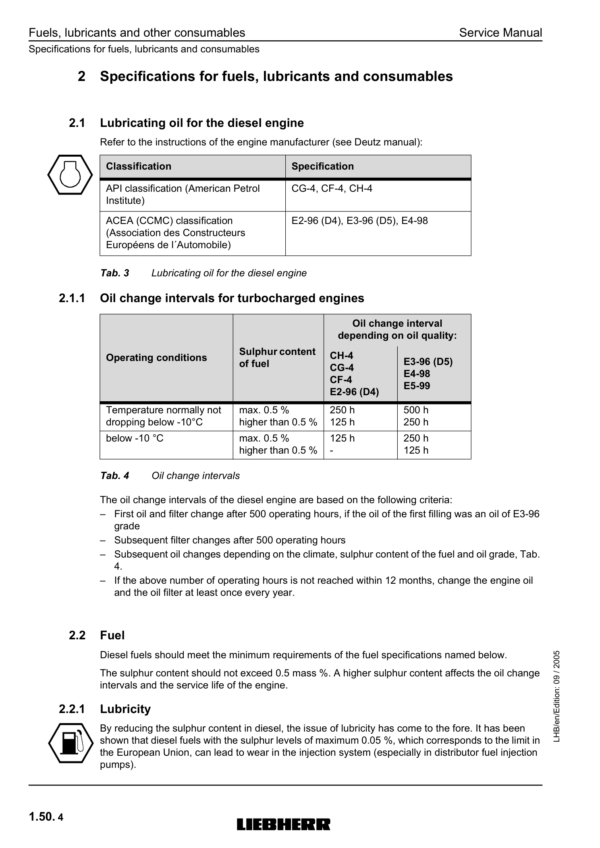

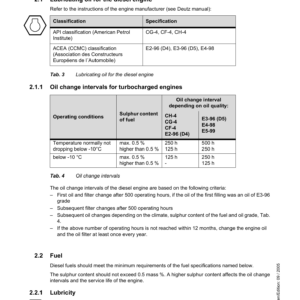

- 1.50 Fuels and lubricants (Page 53)

- 1.55 Lubricant list TE-ML 05 (Page 65)

- 1.56 Lubricant list TE-ML 07 (Page 77)

- 2. Tools (Page 89)

- 2.01 Special tools general (Page 91)

- 2.03 Special tools for diesel engines (Page 99)

- 2.05 Special tools for hydraulic systems (Page 105)

- 2.06 Special tools for electric systems (Page 109)

- 2.07 Special tools for gears (Page 113)

- 2.08 Special tools for axles (Page 115)

- 2.12 Assembly tools for hydraulic cylinders (Page 119)

- 2.13 Mounting device for piston rod bearings (Page 127)

- 2.14 Slotted nut wrench for slewing gear (Page 129)

- 2.15 Mounting device for slewing gear (Page 131)

- 2.16 Mounting device for travel gear (Page 133)

- 3. Technical data/maintenance instructions (Page 135)

- 3.11 Technical data (Page 141)

- 3.32 Inspection and maintenance schedule (Page 171)

- 4. Drive motor (Page 183)

- 5. Coupling/pump distribution gear (Page 199)

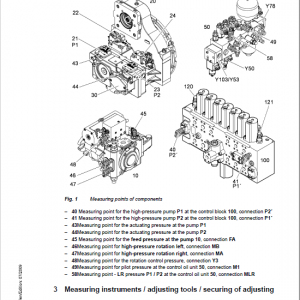

- 6. Hydraulic system (Page 211)

- 6.11 Adjustment protocol A 311 Li 20222-27111 (Page 233)

- 6.11.11 Adjustment protocol A 311 Li 27112- (Page 243)

- 6.22 Layout of hydraulic system A 309 Li – A 311 Li (Page 307)

- 6.30 Adjustment guidelines for hydraulic system A 3109 Li – A 311 Li (Page 341)

- 6.40 Hydraulic system A 309 Li 20221-23502 / A 311 Li 20222-23506 (Page 401)

- 6.40.11 Hydraulic system A 309 Li 23503-27109 / A 311 Li 23507-27111 (Page 411)

- 6.40.21 Hydraulic system A 309 Li 27110- / A 311 Li 27112- (Page 421)

- 7. Hydraulic components (Page 519)

- 7.01 Hydraulic pumps – dismantling, installation and initial operation (Page 523)

- 7.02 Double variable-displacement pump A8VO (Page 527)

- 7.05 LPV variable displacement pump (Page 543)

- 7.20 Cooling unit (Page 591)

- 7.24.1 FMF hydraulic fixed displacement motor (Page 601)

- 7.24.11 FMF hydraulic fixed displacement motor (Page 609)

- 7.26 LMV regulating motor (Page 617)

- 7.27 DMVA regulating motor (Page 633)

- 7.28 Regulating motor A6VE (Page 649)

- 7.30 Hydraulic cylinder (Page 667)

- 7.40 Control oil and regulation unit A 309 Li – A 311 Li (Page 691)

- 7.45 Pilot control unit 4 x (Page 703)

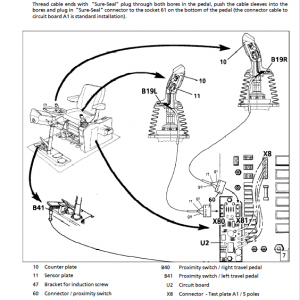

- 7.46.1 Pilot control unit 2 way for travel gear drive (Page 711)

- 7.46.11 Pilot control unit 4 way for travel gear drive (Page 719)

- 7.47 Pilot control valve 2 x for installation kir (Page 725)

- 7.48 Pilot control valve 2 x for support (Page 731)

- 7.49 Pilot control valve 1 x (Page 737)

- 7.75 Rotary connection 1 x (Page 837)

- 7.76 Rotary connection 6 x (Page 843)

- 7.77 Rotary connection 5 x (Page 851)

- 7.78 Rotary connection 7 x (Page 857)

- 7.80 TC valve (Page 863)

- 8. Electrical System (Page 867)

- 8.09 Component arrangement A 309 LI 20221- / A 311 LI 20222- (Page 869)

- 8.20 Electrical system A 309 Li 20221 / A 311 Li 20222- (Page 923)

- 8.22 Electrical system A 309 Li 29269 / A 311 Li 29270 (Page 977)

- 9. Slewing gear mechanism (Page 1665)

- 10. Slewing ring (Page 1695)

- 11. Transmission (Page 1705)

- 12. Axles (Page 1851)

- 13. Steering (Page 2149)

- 14. Oscillating axle support (Page 2233)

- 15. Brake system (Page 2257)

- 16. Special equipment/accessory kits (Page 2283)

- 17. Cab Heater / Air Conditioning System (Page 2607)

- 18. Undercarriage / uppercarriage / attachments (Page 2637)

- 19. Arrangement of Tanks (Page 2644)

- 19.10 Tank arrangement (Page 2646)

Additional information

| PIN/Type | 718, 1036 |

|---|

Be the first to review “Liebherr A311 Litronic Excavator Operators Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.