Liebherr A309 Litronic Excavator Operators Service Repair Manual

Price range: $40.00 through $45.00

Manual Included:

PIN/Type – 717

- Service Repair Manual: 2661 pages

- Operators Manual: 217 pages

PIN/Type – 1035

- Service Repair Manual: 3323 pages

- Operators Manual: 258 pages

Specifications:

- Type: Excavator

- Model: A309

- PIN/Type: 717 & 1035

- Manuals: Operators Manual, Repair Manual

- Language: English

- Format: PDF

- Description

- Additional information

- Reviews (0)

Description

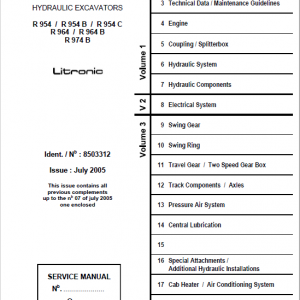

Table of Content – Service Repair Manual (A 309 – Type 1035)

- Book I Chapter 1-19 (Page 1)

- Identification (Page 1)

- Introduction (Page 3)

- Main group directory (Page 5)

- 1 General Information (Page 15)

- 1.02 Changes and modifications to series (Page 19)

- 1.10 Safety instructions (Page 33)

- 1.15 Tightening torques for screws in hydraulic flange connections (Page 45)

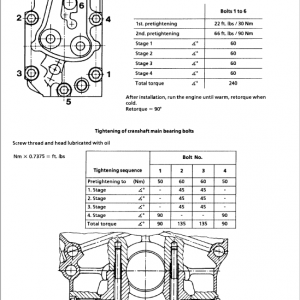

- 1.20 Tightening torques (WN 4037 K) (Page 47)

- 1.21 Tightening torques (Page 51)

- 1.22 Assembly instruction for hydraulic cylinder WN 4121 C (Page 55)

- 1.24 Assembly instruction for hydraulic cylinder WN 4122 B (Page 65)

- 1.25 Tightening torques for piston rod bearing screws (Page 69)

- 1.30 Angle-controlled screw tightening (Page 75)

- 1.35 Hose installation Boom – Stick (Page 83)

- 1.50 Fuels, lubricants and process chemicals (Page 89)

- 1.55 TE_ML05 lubricant list (Page 105)

- 1.56 TE_ML07 lubricant list (Page 121)

- 1.60 Conservation guidelines (Page 133)

- 2 Tools (Page 139)

- 2.01 Special tools – General information (Page 143)

- 2.02 Special tools for diesel engine TCD 2012 (Page 151)

- 2.03 Special tools for diesel engine TCD 2013 (Page 159)

- 2.05 Special tools for hydraulic unit (Page 165)

- 2.06 Special tools for electrical equipment (Page 169)

- 2.07 Special tools for gears (Page 177)

- 2.08 Special tools for axles (Page 179)

- 2.12 Assembly tools for hydraulic cylinders (Page 183)

- 2.13 Mounting device for piston rod bearing (Page 191)

- 2.14 Slotted nut wrench for slewing gear (Page 193)

- 2.15 Mounting device for slewing gear (Page 195)

- 2.16 Mounting device for travel gear (Page 197)

- 3 Technical data / maintenance instructions (Page 199)

- 3.09 Technical data A 309 LI TCD (Page 205)

- 3.21 Inspection and maintenance schedule (Page 233)

- 3.23 Inspection and maintenance schedule (Page 241)

- 3.26 Maintenance- and inspection chart (Page 249)

- 3.43 Adjustment protocol A 309 LI TCD (Page 255)

- 3.75 Adjustment protocol (kits) (Page 393)

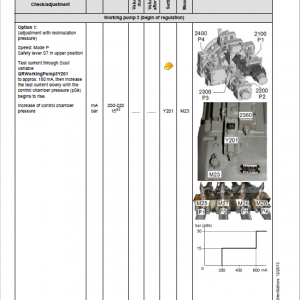

- 3.84 Checking and adjusting tasks (Page 397)

- 3.85 Checking and adjusting tasks (Page 441)

- 3.87 Checking and adjusting tasks (Page 483)

- 3.88 Checking and adjusting tasks (Page 519)

- 3.100 Maintenance tasks (Page 553)

- 3.101 Maintenance tasks for diesel engine (Page 557)

- 3.102 Maintenance tasks for hydraulic system (Page 589)

- 3.103 Maintenance tasks for electrical system (Page 607)

- 3.104 Maintenance tasks for slewing gear mechanism (Page 613)

- 3.105 Maintenance tasks for slewing ring (Page 615)

- 3.106 Maintenance tasks for transmission (Page 617)

- 3.107 Maintenance tasks for travel gear mechanism (Page 621)

- 3.108 Maintenance tasks for axles (Page 625)

- 3.109 Maintenance tasks for travel gear (Page 635)

- 3.110 Maintenance tasks for steering system (Page 641)

- 3.111 Maintenance tasks for oscillating axle support (Page 643)

- 3.112 Maintenance tasks for brake system (Page 645)

- 3.113 Maintenance tasks for operator’s cab and heating (Page 647)

- 3.114 Maintenance tasks for air-conditioning system (Page 651)

- 3.115 Maintenance tasks for uppercarriage, undercarriage and attachment (Page 657)

- 3.116 Maintenance tasks for quick-change systems (Page 665)

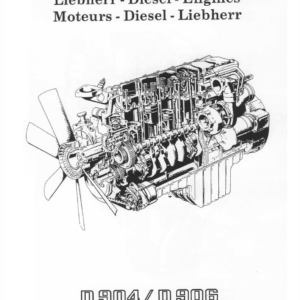

- 4 Engine (Page 671)

- 4.04 Technical data of diesel engines (Page 673)

- 4.06 Technical data of diesel engines (Page 677)

- 4.10 Technical data of diesel engines (Page 681)

- 4.25 Installation and check list (Page 685)

- 4.30 Liebherr diesel particle filter accessory kit (Page 691)

- 4.40 Datalogger version 2.3.00 (Page 719)

- 4.41 Datalogger software version 2.3.09 (Page 751)

- 5 Coupling / Splitterbox (Page 783)

- 5.10 Coupling (Page 785)

- 6 Hydraulic system (Page 791)

- 6.10 LSC system (Page 793)

- 6.20 Design of hydraulic system (Page 801)

- 6.25 Design of hydraulic system (Page 813)

- 6.30 Design of hydraulic system (Page 825)

- 6.40 Hydraulic system (Page 837)

- 6.52 Hydraulic system (Page 845)

- 6.54 Hydraulic unit with dozer blade (Page 853)

- 6.60 Hydraulic system (Page 861)

- 6.73 Hydraulic system with dozer blade (Page 925)

- 6.76 Hydraulic system (Page 933)

- 6.77 Hydraulic system (Page 941)

- 6.78 Hydraulic system (Page 949)

- 7 Hydraulic components (Page 957)

- 7.02 Hydraulic pumps – dismantling, installation and commissioning (Page 961)

- 7.10 DPVO variable-displacement pump (Page 969)

- 7.20 Cooling unit (Page 983)

- 7.24 FMF hydraulic fixed displacement motor (Page 989)

- 7.25 FMF hydraulic fixed displacement motor (Page 997)

- 7.26 DMVA regulating motor (Page 1005)

- 7.27 DMVA regulating motor (Page 1023)

- 7.28 Regulating motor A6VE (Page 1041)

- 7.29 Regulating motor A6VE (Page 1057)

- 7.30 Hydraulic cylinder (Page 1075)

- 7.32 Hydraulic double plunger cylinder (Page 1093)

- 7.42 Control oil unit (Page 1107)

- 7.45 Pilot control unit 4 x (Page 1113)

- 7.46 4x pilot control unit for travel drive (Page 1121)

- 7.47 Pilot control unit 2x (Page 1127)

- 7.48 Pilot control valve 2 x (Page 1133)

- 7.56 LSC control valve block (Page 1139)

- 7.58 LSC control block (Page 1209)

- 7.60 LSC control valve block (Page 1275)

- 7.75 Rotary connection 1x (Page 1335)

- 7.76 Rotary connection 6x (Page 1341)

- 7.77 Rotary connection 5x (Page 1347)

- 7.78 Rotary connection 7x (Page 1353)

- 7.80 Double load holding valve (Page 1359)

- 7.82 Support valve / double lowering brake valve (Page 1365)

- 7.86 Double load-holding valve for regulating cylinder (Page 1371)

- 7.95 Accumulator (Page 1379)

- 8 Electrical system (Page 1401)

- 8.01 Overview of electrical symbols (Page 1405)

- 8.02 Notes regarding the electrical system (Page 1417)

- 8.10 Arrangement of components (Page 1421)

- 8.20 Arrangement of components (Page 1441)

- 8.30 Arrangement of components (Page 1461)

- 8.40 Electrical system / basic machine (Page 1479)

- 8.50 Electrical system (basic machine) (Page 1545)

- 8.51 Electrical system / basic machine (Page 1611)

- 8.56 Electrical system / basic machine (Page 1675)

- 8.57 Electrical system / basic machine (Page 1741)

- 8.60 Electrical system (basic machine) (Page 1807)

- 8.61 Electrical system / basic machine (Page 1869)

- 8.66 Electrical system / basic machine (Page 1933)

- 8.70 UEC central control system (Page 1999)

- 8.72 UEC central control system (Page 2011)

- 8.74 UEC central control system (Page 2023)

- 8.76 UEC error codes (Page 2035)

- 8.80 Menu control (Page 2047)

- 8.81 Menu control (Page 2077)

- 8.86 Electronic travel drive control (Page 2133)

- 8.90 Slip ring – rotary connection (Page 2143)

- 8.100 Directory of electrical kits (Page 2149)

- 8.101 Control system extension UEC 2 (Page 2151)

- 8.102 Control system extension UEC 2 (Page 2173)

- 8.103 Particle filter kit (Page 2200)

- 8.104 Stroke limitation with proximity switches (Page 2210)

- 8.105 Dozer blade (Page 2220)

- 8.106 Overload warning system, switchable (Page 2226)

- 8.107 Proportional control (Page 2238)

- 8.108 Rear space camera monitoring system (Page 2256)

- 8.109 Rear space and side camera monitoring system (Page 2258)

- 9 Slewing gear mechanism (Page 2260)

- 9.10 Slewing gear mechanism (Page 2262)

- 9.20 Slewing gear brake (Page 2274)

- 9.24 Slewing gear brake (Page 2282)

- 10 Slewing ring (Page 2290)

- 10.10 Slewing ring (Page 2292)

- 11 Two Speed Gear Box / Travel Gear (Page 2300)

- 11.20 2 HL 270 / 290 transmission (Page 2302)

- 11.32 HBGV block for 2 HL 270 / 290 (Page 2332)

- 11.60 FAT 350 travel gear system (Page 2338)

- 11.65 Travel brake (Page 2348)

- 12 Axles / Track Components (Page 2354)

- 12.04 Steering axle 212 (Page 2356)

- 12.06 Rigid axle 112 (Page 2370)

- 12.08 Differential for axles 112 / 212 (Page 2382)

- 12.12 Steering axle and steered rear axle 262 LD (Page 2394)

- 12.14 Rigid axle 162 LD (Page 2408)

- 12.16 Differential for axles 162 LD/262 LD (Page 2418)

- 12.20 Steering axle 262 (Page 2430)

- 12.22 Rigid axle 162 (Page 2442)

- 12.24 Differential for 162 / 262 axles (Page 2452)

- 12.30 MS – E 3050 / 3060 steering axle (Page 2462)

- 12.32 MT – E 3050 / 3060 rigid axle (Page 2478)

- 12.34 MS/MT – E 3050 / 3060 drive unit and differential (Page 2492)

- 12.50 Tyres and tyre pressure (Page 2498)

- 12.60 Chassis / drive (Page 2502)

- 12.62 Technical data / tightening torques (Page 2508)

- 12.64 Technical data / tightening torques (Page 2510)

- 12.66 Wear of chassis parts (Page 2512)

- 12.67 D4L wear limits (Page 2516)

- 12.69 Wear limits – B60 (Page 2518)

- 12.72 Chain (Page 2520)

- 12.75 Tensioning unit (Page 2530)

- 12.78 Idler (Page 2536)

- 12.81 Running roller (Page 2540)

- 12.82 Idler (Page 2542)

- 12.84 Support roller (Page 2544)

- 12.86 Slide ring seal (Page 2548)

- 13 Steering (Page 2550)

- 13.10 Hydraulic steering system (Page 2552)

- 13.20 Steering valve (Page 2558)

- 13.25 Steering valve (Page 2566)

- 13.32 Steering cylinders (Page 2574)

- 13.35 Steering cylinder (Page 2580)

- 13.50 Four-wheel steering (Page 2586)

- 14 Oscillating axle support (Page 2614)

- 14.10 Oscillating axle support with automatic control (Page 2616)

- 14.20 Support cylinders (Page 2626)

- 15 Brake system (Page 2634)

- 15.05 Operating pressures of the brake system (Page 2636)

- 15.10 Hydraulic brake system (Page 2638)

- 15.20 Compact brake block (Page 2654)

- 16 Special equipment / accessory kits (Page 2660)

- 16.03 Pipe fracture safety valve for boom cylinders (Page 2666)

- 16.04 Pipe fracture safety valve for boom cylinders (Page 2680)

- 16.06 Pipe fracture safety valve for stick cylinder (Page 2692)

- 16.10 Pipe fracture safety valve for regulating cylinder (Page 2704)

- 16.12 Overload warning system (Page 2714)

- 16.14 Switchable overload warning system (Page 2724)

- 16.16 Stroke limitation with proximity switches (Page 2738)

- 16.18 Stroke limitation with angle sensors (Page 2752)

- 16.20 Stroke limitation with angle sensors (Page 2766)

- 16.22 Stick cylinder shut-down with proximity switch (Page 2786)

- 16.32 Hydraulic quick change adapter (Page 2798)

- 16.36 Hydraulic-electric LIKUFIX coupling system (Page 2808)

- 16.42 Accessory kit AS1 (Page 2828)

- 16.44 AS 1 proportional control (Page 2840)

- 16.46 Accessory kit AHS 1 (Page 2860)

- 16.52 AHS 11 accessory kit with Tool Control (Page 2868)

- 16.53 Changeover of control for AHS 11 with Tool Control (Page 2898)

- 16.54 Accessory kit AHS 11 with Tool Control plus (Page 2906)

- 16.55 Changeover of control for AHS 11 with Tool Control plus (Page 2936)

- 16.56 AHS 11 proportional control (Page 2944)

- 16.60 AHS 12 accessory kit with Tool Control (Page 2980)

- 16.61 Changeover of control for AHS 12 with Tool Control (Page 3018)

- 16.62 Accessory kit AHS 12 with Tool Control plus (Page 3026)

- 16.63 Changeover of control for AHS 12 with Tool Control plus (Page 3066)

- 16.64 AHS 12 proportional control (Page 3074)

- 16.70 Camera monitoring (Page 3112)

- 16.80 Hydraulic cab elevation system (Page 3126)

- 16.81 Hydraulic operator’s cab elevation system (Page 3144)

- 16.84 Bypass filter – RT (Page 3162)

- 16.86 Bypass filter – Liebherr (Page 3168)

- 16.88 Bypass filter- KleenOil (Page 3176)

- 16.90 Reversible fan drive (Page 3184)

- 16.92 Generator drive accessory kit (Page 3198)

- 17 Cab / Heater / Air Conditioning System (Page 3210)

- 17.30 Heating / air-conditioning system (Page 3212)

- 18 Undercarriage / Uppercarriage / Attachments (Page 3234)

- 18.25 Semi-automatic central lubrication system (Page 3236)

- 18.30 Automatic central lubrication system (Page 3248)

- 18.34 Lubricant pump (Page 3262)

- 18.38 SX-E progressive distributor (Page 3272)

- 18.42 MX-F progressive distributor (Page 3284)

- 18.46 Repair instructions for lubrication hoses (Page 3294)

- 19 Tank arrangement (Page 3296)

- 19.10 Tank arrangement (Page 3298)

- 19.20 Tank arrangement (Page 3312)

Additional information

| PIN/Type | 717, 1035 |

|---|

Be the first to review “Liebherr A309 Litronic Excavator Operators Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.