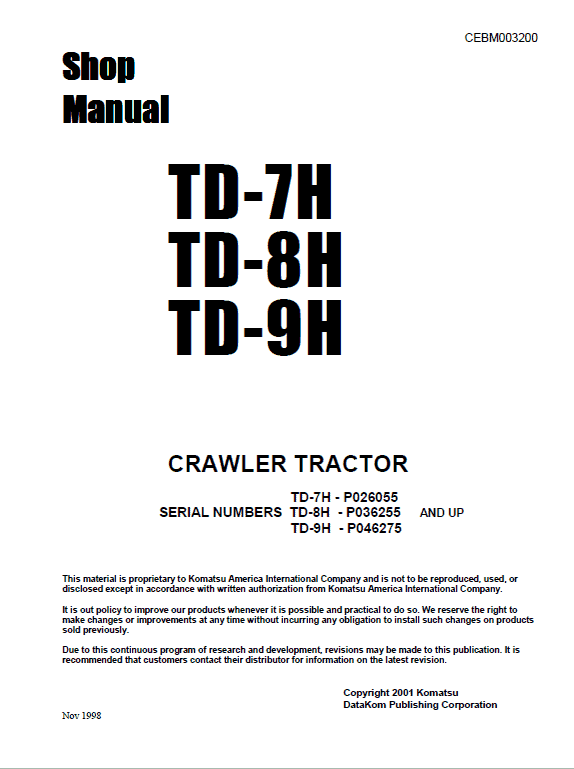

Komatsu Dresser TD7H, TD8H, TD9H Dozer Service Manual

$34.00

Manual Included:

- Shop Manual: 1072 pages

Specifications:

- Brand: Komatsu

- Model: TD7H, TD8H, TD9H

- Type: Bulldozer

- Serial Numbers:

25501 and up

35501 and up

45501 and up - Manuals: Shop Manual

- Publication Number: CEBM789H04

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Contents

INTRODUCTION – SECTION 1

MISCELLANEOUS – SECTION 2

BRAKES – SECTION 4

STEERING – SECTION 5

COOLING – SECTION 6

DRIVE TRAIN – SECTION 7

DIRECT DRIVE – SECTION 7A

TORQUE CONVERTER – SECTION 7B

TRANSMISSION – SECTION 7C

STEERING DRIVE – SECTION 7E

SPROCKET DRIVE – SECTION 7F

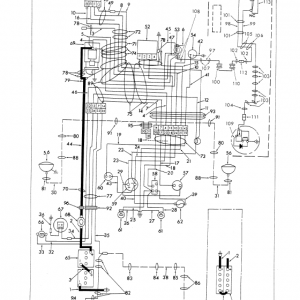

ELECTRICAL – SECTION 8

FRAME – SECTION 9

HYDRAULICS – SECTION 10

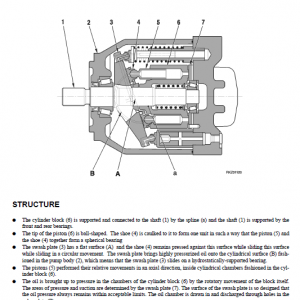

PUMPS AND MOTORS – SECTION 10A

VALVES – SECTION 10B

CYLINDERS – SECTION 10C

INSTRUMENTS – SECTION 11

POWER – SECTION 12

SUPERSTRUCTURE – SECTION 13

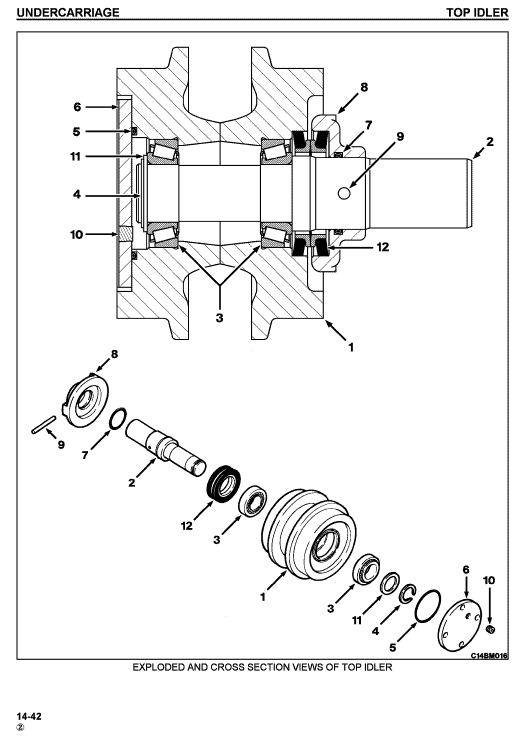

UNDERCARRIAGE – SECTION 14

TRACK CHAIN – SECTION 15

MOUNTED EQUIPMENT – SECTION 17

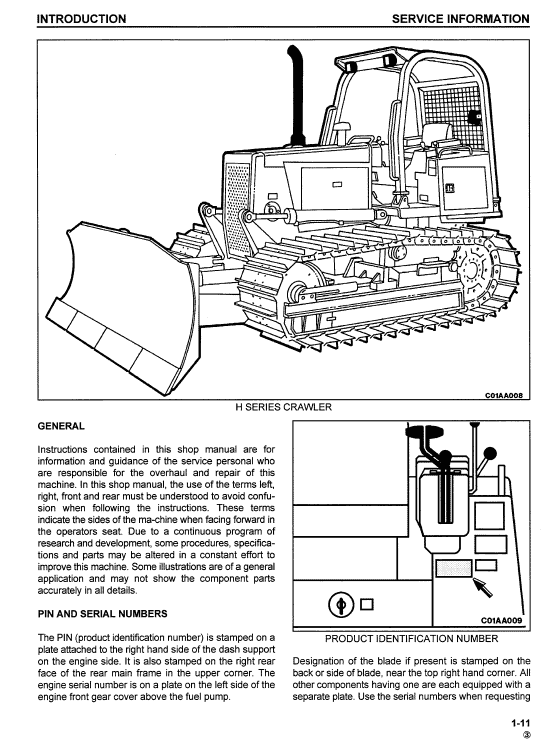

This Dresser shop manual includes information for locations, specifications, service/special tools, tolerances, pressures, lubricants and sealants, special torques, tests and adjustments, assembly tips and service bulletin references for various components of the machine. This shop manual is divided into major sections. These sections are indexed by title and divided by individual section index tab. To use this shop manual, locate the section required and turn to that section index tab.

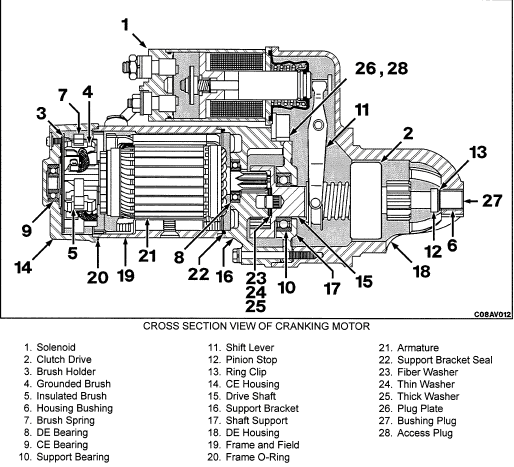

The cranking motor provides high starting torque by using a high speed motor through an offset gear reduction unit. It produces up to 4 hp (3 kW) of output.

The cranking motor has a totally enclosed, solenoid (1) operated mechanism for positive shift of the pinion into engagement. The solenoid waffle type contact faces and a solid link between the contact disc assembly and the solenoid plunger helps prevent contact sticking.

The shift lever (11) of the Dresser TD7H, TD8H, TD9H Dozer is attached to the plunger on one end and mates with a collar on the clutch drive (2) at the other end. The action of the lever forces the drive pinion into engagement with the engine flywheel when the magnetic pull of the solenoid draws the plunger in.

A medium duty, 5 roll overrunning drive is used for low overrun friction and long operating life. The drive shaft (15) is supported by a ball bearing (10) at the gear reduction end and by a sleeve bushing (6) at the drive end. An external helical spline on the drive shaft of the Dresser TD7H, TD8H, TD9H Dozer turns the pinion as it moves into engagement with the engine flywheel. An internal gear at the gear reduction end of the drive shaft is driven by the armature (21) shaft gear at a speed of one drive shaft revolution for each 3-7/s revolutions of the armature.

The armature is dynamically balanced and rides in sealed ball bearings (8 and 9)at each end. Steel banding and varnish impregnation are used for added armature strength. The molded bar commutator receives electrical power through radially positioned, one piece brushes (4 and 5). Constant pressure brush springs (7) are used for even brush wear and long brush life.

Be the first to review “Komatsu Dresser TD7H, TD8H, TD9H Dozer Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.