Komatsu D65EX-17, D65PX-17, D65WX-17 Dozer Service Manual

$36.00

Manual Included:

- Shop Manual: 1848 pages

Specifications:

- Brand: Komatsu

- Model: D65EX-17, D65PX-17, D65WX-17

- Type: Dozer

- Serial Number: 1001 and up

- Manuals: Shop Manual

- Publication Number: SEN05536-01

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Contents

00 Index and foreword

Foreword and general information

01 Specification

Specification and technical data

10 Structure, function and maintenance standard

Engine and cooling system

Power train

Undercarriage and frame

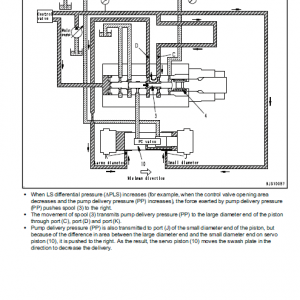

Hydraulic system

Work equipment

Cab and its attachments

Electrical system

20 Standard value table

Standard service value table

30 Testing and adjusting

40 Troubleshooting

80. Appendix

90 Diagrams and drawings

Composition of shop manual

• This shop manual contains the necessary technical information for services performed in a workshop. For ease of understanding, the manual is divided into the following sections.

00. Index and foreword

01. Specification

• This section explains the specifications of the machine.

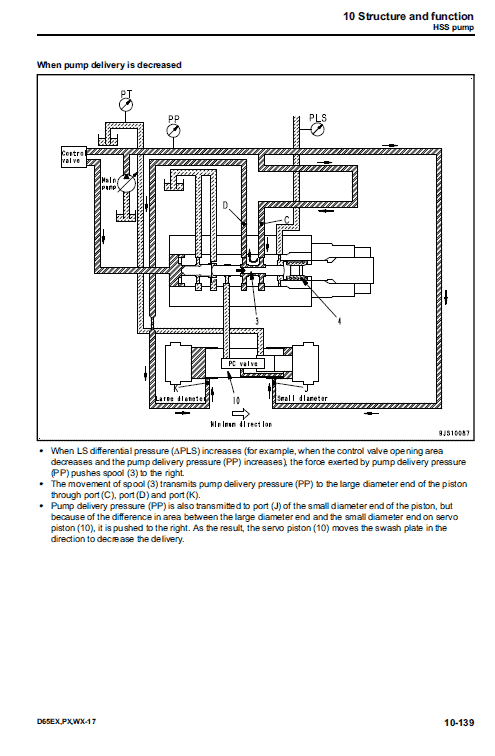

10. Structure and function

• This section explains the structure and function of each component. It serves not only to give an understanding for the structure of each component, but also serves as reference material for troubleshooting.

20. Standard value table

• This section explains the standard values for new machine and judgement criteria for testing, adjusting, and troubleshooting. This standard value table is used to check the standard values in testing and adjusting and to judge parts in troubleshooting.

30. Testing and adjusting

This section explains measuring tools and measuring methods for testing and adjusting, as well as the adjusting method of each part. The standard values and judgment criteria for “Testing and adjusting” are explained in “Standard value table”.

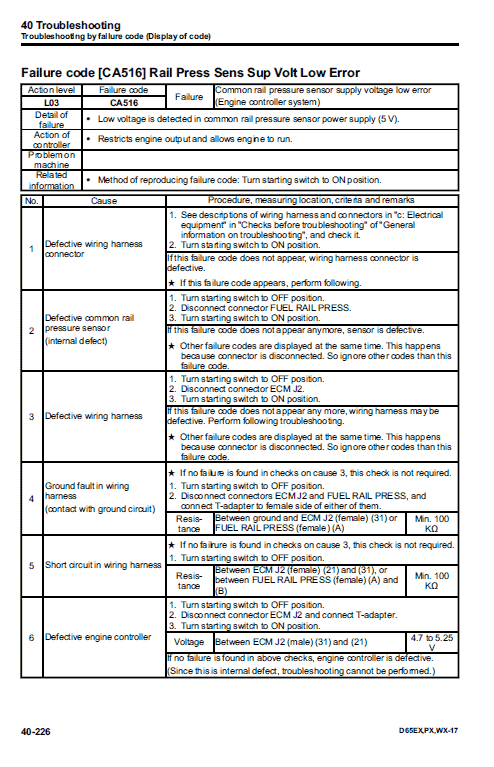

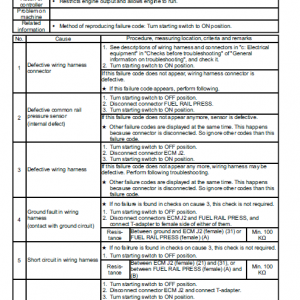

40. Troubleshooting

• This section explains how to find out failed parts and how to repair them. The troubleshooting is divided by failure modes. The “S mode” of the troubleshooting related to the engine may be also explained in the Chassis volume and Engine volume. In this case, see the Chassis volume.

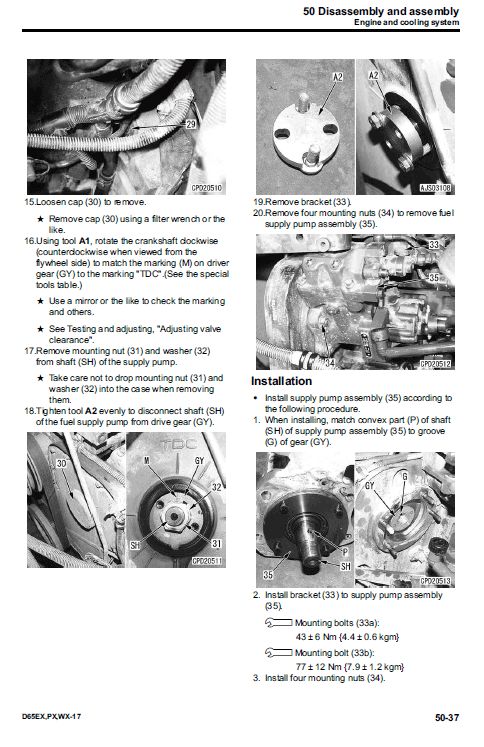

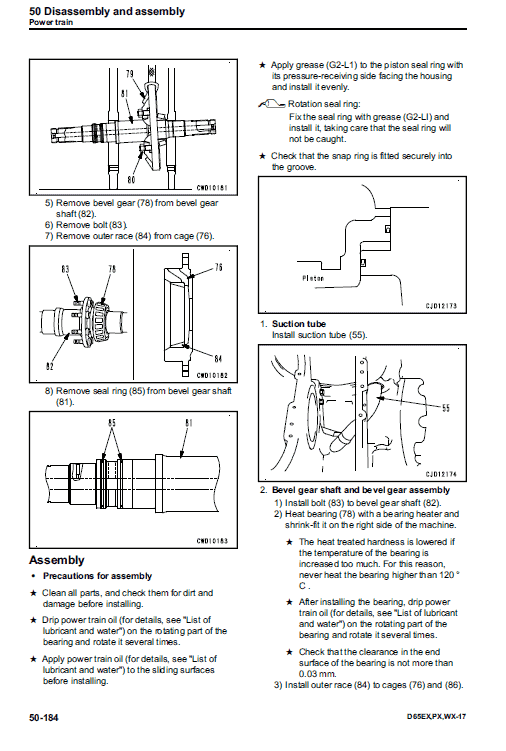

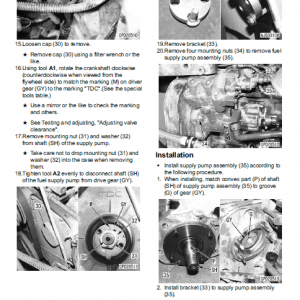

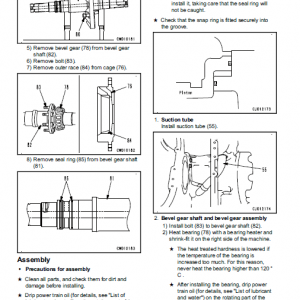

50. Disassembly and assembly

• This section explains the special tools and procedures for removing, installing, disassembling, and assembling each component, as well as precautions for them. In addition, tightening torque, and quantity and weight of coating material, oil, grease, and coolant necessary for the work are also explained.

60. Maintenance standard

• This section gives maintenance standard values of each component. The maintenance standard subsection explains the criteria and remedies for disassembly and service.

80. Appendix

• The section contains the equipment which can not be class, field in the other sections.

This section explains the structure, function, testing, adjusting, and troubleshooting for the equipment.

90 Diagrams and drawings

• This section gives hydraulic circuit diagrams and electrical circuit diagrams.

General information on troubleshooting

The aim of troubleshooting is to pinpoint the basic cause of the failure, to carry out repairs swiftly, and to prevent reoccurrence of the failure. When carrying out troubleshooting, an important point is of course to understand the structure and function. However, a short cut to effective troubleshooting is to ask the operator various questions to form some idea of possible causes of the failure that would produce the reported symptoms.

1. When carrying out troubleshooting, do not hurry to disassemble the components.

If components are disassembled immediately after any failure occurs: Parts that have no connection with the failure or other unnecessary parts will be disassembled.

• It will become impossible to find the cause of the failure.

It will also cause a waste of manhours, parts, or oil or grease, and at the same time, will also lose the confidence of the user or operator.

For this reason, when carrying out troubleshooting, it is necessary to carry out thorough prior investigation and to carry out troubleshooting in accordance with the fixed procedure.

2. Points to ask the user or operator

1) Have any other problems occurred apart from the problem that has been reported

2) Was there anything strange about the machine before the failure occurred

3) Did the failure occur suddenly, or were there problems with the machine condition before this

4) Under what conditions did the failure occur

5) Had any repairs been carried out before the failure When were these repairs carried out

6) Has the same kind of failure occurred before

3. Check before troubleshooting

1) Are abnormal symptoms detected in the machine

2) Make checks before starting day’s work.

3) Make checks of other items.

4) Check other maintenance matters which can be checked externally and are considered to be necessary.

4. Confirming failure

See the extent of the failure by yourself, and judge whether it is a real failure or a problem caused by the handling or operating the machine.

a When operating the machine to reenact the troubleshooting symptoms, do not perform any inspection or measurement that may make the problem worse.

Be the first to review “Komatsu D65EX-17, D65PX-17, D65WX-17 Dozer Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.