Komatsu D65EX-15, D65PX-15, D65WX-15 Dozer Service Manual

$35.00

Manual Included:

- Shop Manual: 922 pages and 1229 pages

Specifications:

- Brand: Komatsu

- Model: D65EX-15, D65PX-15, D65WX-15

- Type: Dozer

- Serial Number:

67001 and up

69001 and up - Manuals: Shop Manual

- Publication Numbers: SEN00046-09 and SEBM029508

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Contents

00 Index and foreword

Foreword and general information

01 Specification

Specification and technical data

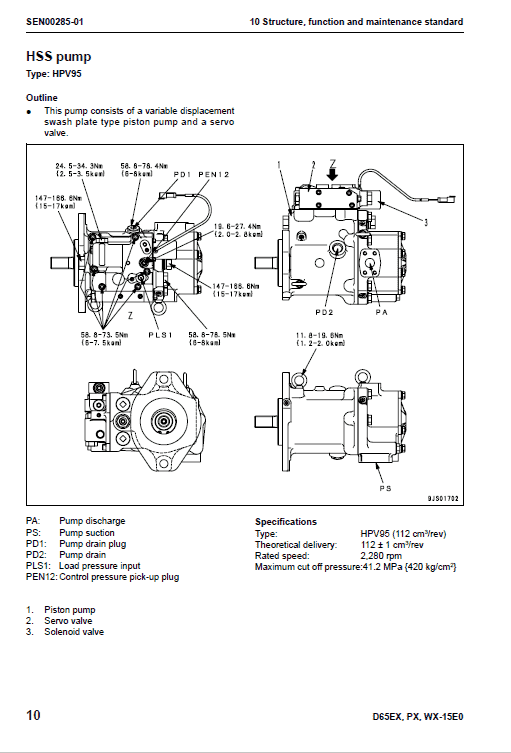

10 Structure, function and maintenance standard

Engine and cooling system

Power train

Undercarriage and frame

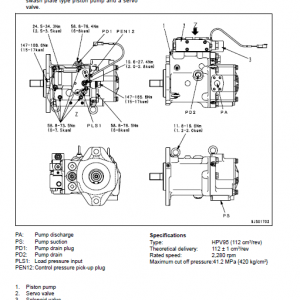

Hydraulic system

Work equipment

Cab and its attachments

Electrical system

20 Standard value table

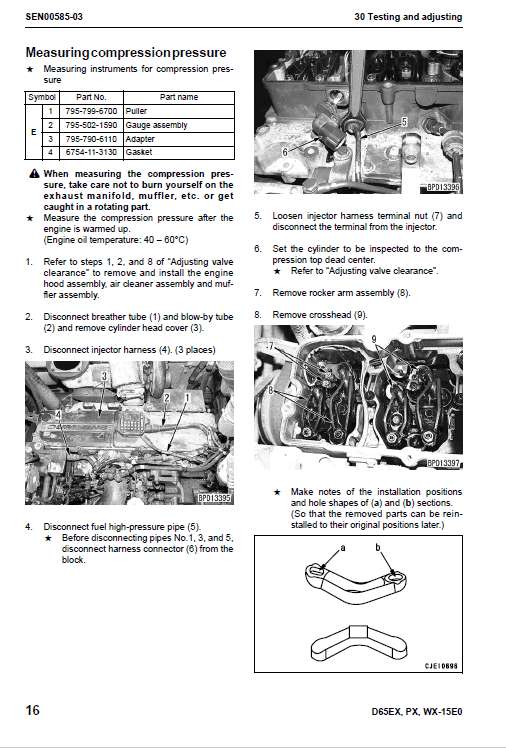

30 Testing and adjusting

40 Troubleshooting

80. Appendix

90 Diagrams and drawings

Composition of shop manual

• This shop manual contains the necessary technical information for services performed in a workshop. For ease of understanding, the manual is divided into the following sections.

00. Index and foreword

01. Specification

• This section explains the specifications of the machine.

10. Structure and function

• This section explains the structure and function of each component. It serves not only to give an understanding for the structure of each component, but also serves as reference material for troubleshooting.

20. Standard value table

• This section explains the standard values for new machine and judgement criteria for testing, adjusting, and troubleshooting. This standard value table is used to check the standard values in testing and adjusting and to judge parts in troubleshooting.

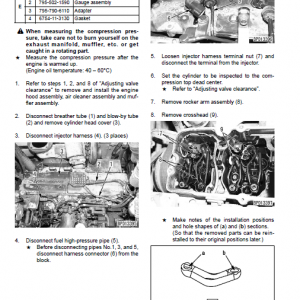

30. Testing and adjusting

This section explains measuring tools and measuring methods for testing and adjusting, as well as the adjusting method of each part. The standard values and judgment criteria for “Testing and adjusting” are explained in “Standard value table”.

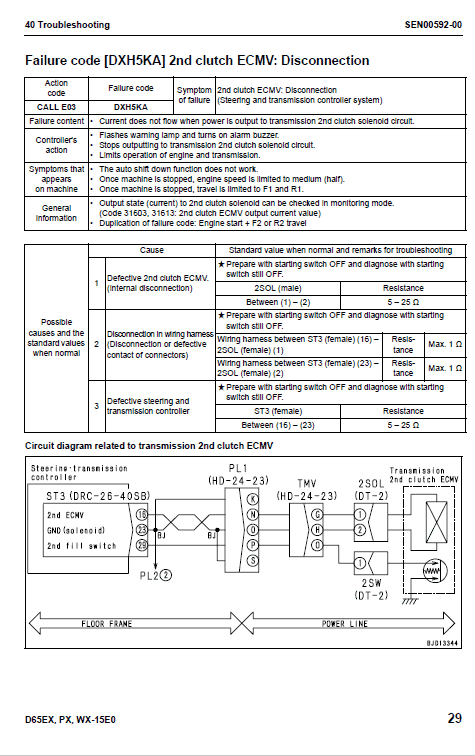

40. Troubleshooting

• This section explains how to find out failed parts and how to repair them. The troubleshooting is divided by failure modes. The “S mode” of the troubleshooting related to the engine may be also explained in the Chassis volume and Engine volume. In this case, see the Chassis volume.

50. Disassembly and assembly

• This section explains the special tools and procedures for removing, installing, disassembling, and assembling each component, as well as precautions for them. In addition, tightening torque, and quantity and weight of coating material, oil, grease, and coolant necessary for the work are also explained.

60. Maintenance standard

• This section gives maintenance standard values of each component. The maintenance standard subsection explains the criteria and remedies for disassembly and service.

80. Appendix

• The section contains the equipment which can not be class, field in the other sections.

This section explains the structure, function, testing, adjusting, and troubleshooting for the equipment.

90 Diagrams and drawings

• This section gives hydraulic circuit diagrams and electrical circuit diagrams.

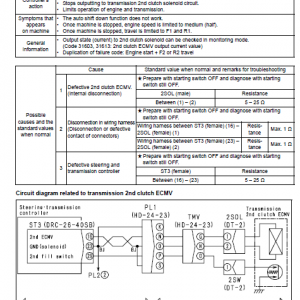

Classification and procedures of troubleshooting

Troubleshooting procedures when a failure code has been recorded:

When no action code is displayed on the monitor panel, display a failure code in the failure code display mode (electrical system, mechanical system) on the monitor display (EMMS).

When a failure code has been recorded, carry out the troubleshooting of the relevant [failure code] in accordance with the displayed failure code.

– Since a failure code flashes when a failure is detected, the failure has not always been corrected even if it lights when the starting switch is set to ON. (For some codes, failures can be detected by only turning the starting switch ON.)

– When a failure code has been recorded, be sure to perform the duplication operation corresponding to the failure code and confirm if the failure has still remained or has been already corrected.

(For the duplication method, refer to the troubleshooting relevant to the failure code.) 3. Troubleshooting procedures when no action code is displayed and a failure code has not been recorded:

When a failure code has not been recorded in the monitor panel (EMMS), a failure that the machine cannot diagnose by itself is supposed to have occurred in the electrical system or the hydraulic and mechanical system.

In this case, check again a symptom supposed to be a failure and select the relevant symptom out of the table of Symptom supposed to be failure and troubleshooting No. Then, carry out the troubleshooting in the [E-Mode], [H-Mode] or [S-Mode] related to the symptom.

Be the first to review “Komatsu D65EX-15, D65PX-15, D65WX-15 Dozer Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.