Komatsu D32P-1, D38P-1, D39P-1 Dozer Service Manual

$34.00

Manual Included:

- Shop Manual: 620 pages and 636 pages

Specifications:

- Brand: Komatsu

- Model: D32P-1, D38P-1, D39P-1

- Type: Dozer

- Serial Number:

P075501 and up (D32P-1)

P085501 and up (D38P-1)

P095501 and up (D39P-1)

P075718 and up (D32E-1, D32P-1)

P085799 and up (D38E-1, D38P-1)

P095872 and up (D39E-1, D39P-1)

P076093 and up (D32E/P-1A, D38E/P-1A)

P086239 and up (D38E/P-1A)

P096338 (D39E/P-1A) - Manuals: Shop Manual

- Publication Numbers: CEBM004302(Sep 2003), CEBM003100(Nov 1998) and CEBM000301( Mar 1997)

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Contents

This shop manual includes information for locations,

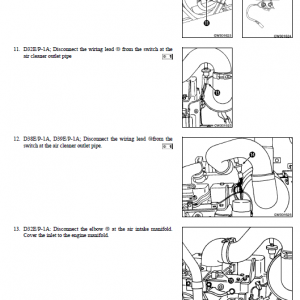

INTRODUCTION SECTION 1 specifications, service/special tools, tolerances, pressures, lubricants and sealants, special torques, tests and adjustments, assembly tips and service bulletin references for various components of the machine. This shop manual is divided into major sections. These sections are indexed by title and divided by individual section index tab. To use this shop manual, locate the section required and turn to that section index tab.

MISCELLANEOUS SECTION 2

COOLING SECTION 6

DRIVE TRAIN SECTION 7

TORQUE CONVERTER SECTION 7B

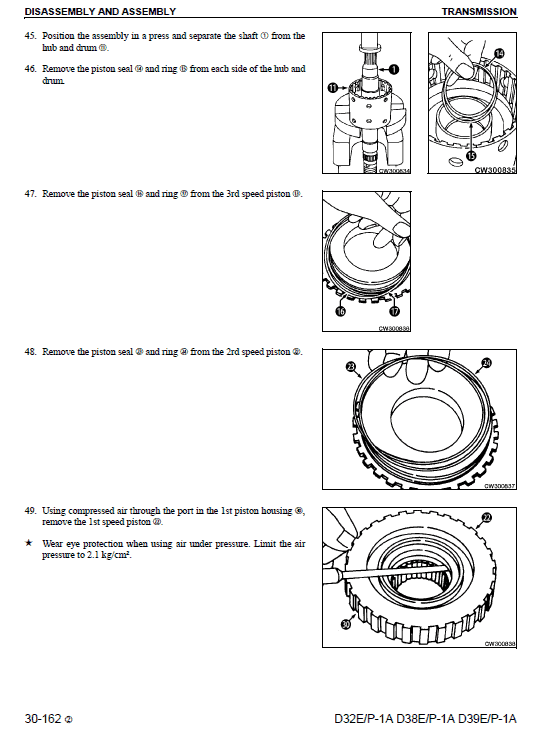

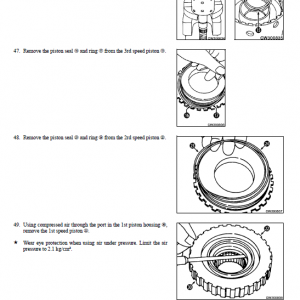

TRANSMISSION SECTION 7C

STEERING DRIVE SECTION 7E

SPROCKET DRIVE SECTION 7F

ELECTRICAL SECTION 8

HYDRAULICS SECTION 10

PUMPS AND MOTORS SECTION 10A

CONTROL VALVE SECTION 10B

CYLINDERS SECTION 10C

POWER SECTION 12

UNDERCARRIAGE SECTION 14

TRACK CHAIN SECTION 15

MOUNTED EQUIPMENT SECTION 17

MAINTENANCE

The track links have only one wearing surface which contacts the track rollers, front idler and track idlers. However, it usually becomes necessary to replace pins and bushings before the links wear out, and it is a matter of judgement then whether the links are good enough to justify a new set of pins and bushings. Only the wear on the outside of the bushings is visible. Wear on the pins and interior of the bushings is indicated by track stretch (forward adjustment of the front idler). The amount of wear can be determined by measuring the pitch length of the track (distance between centers of pins) under tension and comparing it with new and maximum allowable pitch lengths listed in SECTION 14. Sprocket wear must also be considered in conjunction with track chain wear.

Wear of the sprocket teeth decreases the pitch length of the sprocket, while wear of pins and bushings increases the pitch length of the track. The results are that the pitch lengths of the sprocket and track becomes more and more out of phase, and the bushings ride higher on the sprocket teeth. Combined wear of sprocket and track should never be allowed to reach this point.

Whenever new or rebuilt track chains are installed, the sprocket should also be replaced or interchanged to present the better side of teeth to the bushings. Never remove one link to bring a stretched track to within the range of proper track adjustment. A track that is worn badly enough to take up the length of one link, will be so far out of pitch that the increased wear on the sprocket will far more than offset the saving obtained by the removal of one link in the track chain.

Be the first to review “Komatsu D32P-1, D38P-1, D39P-1 Dozer Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.