Kawasaki 95ZIV Wheel Loader Repair Service Manual

$34.00

Machinery Type: 95ZIV or 95Z4 Wheel Loader

Language English

Format: PDF

Kawasaki 95ZIV Wheel Loader Repair Service Manual – 462 Pages

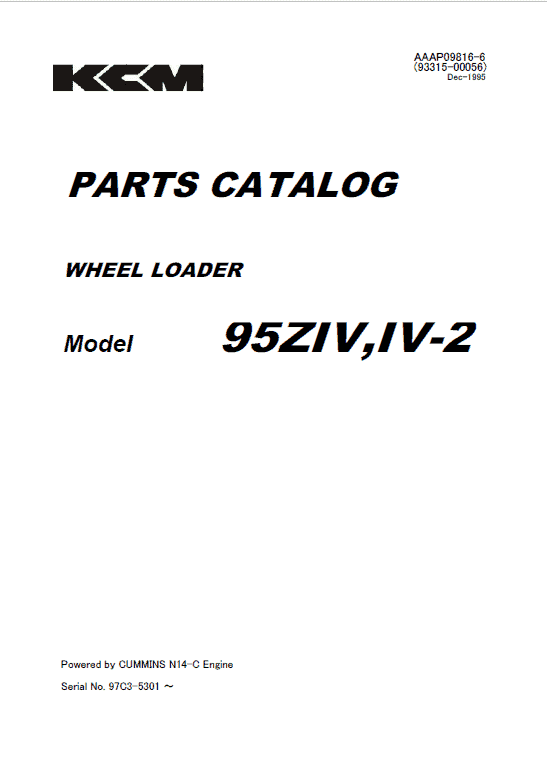

Kawasaki 95ZIV Wheel Loader Parts Catalog Manual – 380 & 452 Pages

- Description

- Reviews (0)

Description

Kawasaki 95ZIV Wheel Loader Service Manual

Machinery Type: 95ZIV or 95Z4 Wheel Loader

Language English

Format: PDF

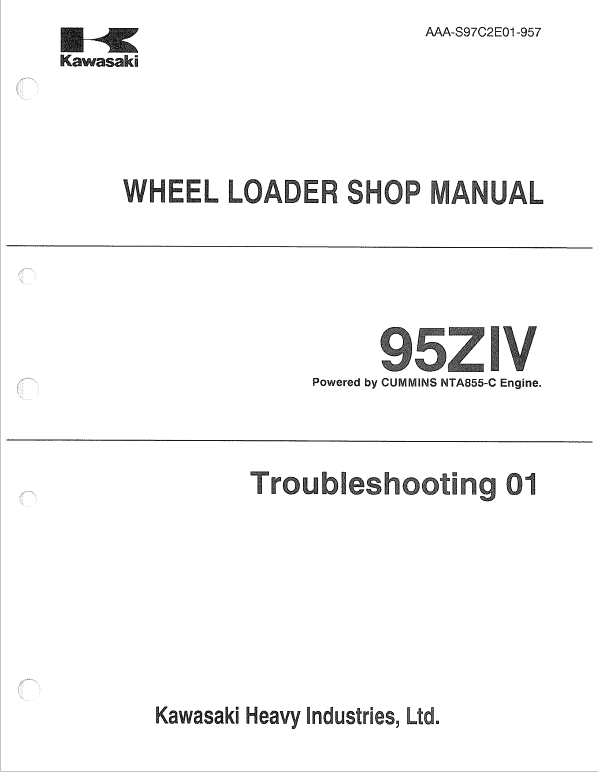

Kawasaki 95ZIV Wheel Loader Repair Service Manual – 462 Pages

Kawasaki 95ZIV Wheel Loader Parts Catalog Manual – 380 & 452 Pages

Manual Details

This manual contains guidelines on repair and maintenance work for the 95ZIV Loader. All explanations, drawings and photographs are current at the time of going to press.

Repair and maintenance work should be carried out systematically and logically after thoroughly reading and understanding this manual to ensure that the shovel loader gives reliable, long-term service.

The manual is structured as follows to make it easy to use

SHOP SERVICE MANUAL CONTENT:

- 01 GENERAL OUTLINE

- 10 FUNCTIONS AND CONSTRUCTION

- 20 INSPECTION AND ADJUSTMENT

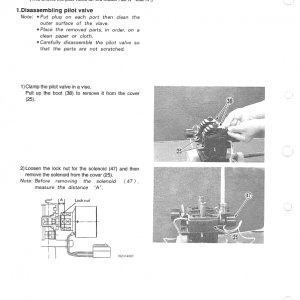

- 30 DISASSEMBLY AND ASSEMBLY

- 40 MAINTENANCE STANDARDS

The most important maintenance operations are those related to safety. The points that have special significance from the safety point-of-view are indicated with a A mark in this manual.

Reinstalling gear pump assembly Important Note

1) Be sure to remove all caps, plugs, tape, etc. from the pump and pour new oil from the outlet and Inlet ports Into the pump to form an oil film Inside the pump.

2) While reinstalling the gear pump, take care not to allow dust, dirt, or foreign material Into the case.

3) Check the oil level of the hydraulic tank.

4) Close the cap of the hydraulic tank, and remove the plugs of the pump suction pipe. Pour hydraulic oil Into the plug port until the oil overflows from the port (approx. 4 .e ).

5) Operate the engine at low-idling speed for 5 minutes or more. Do not operate any hydraulic functions during this period.

Note : If the engine speed Is set to high-idling Just after starting, the pump may be seized.

6) Move each cylinder almost full stroke 5-6 times. Do not fully extend or retract any cylinder during this period.

7) Confirm that there Is no abnormal heat, noise, or abnormal operation of the system during this break-In period.

8) lnspect the hydraulic oil sight gauge and confirm that there are no bubbles In the hydraulic oil. Bubbles may indicate a suction side air leak that must be corrected to prevent premature pump failure.

Be the first to review “Kawasaki 95ZIV Wheel Loader Repair Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.