John Deere TeamMate IV 1200 Series Inboard Planetary Axles Component Technical Manual

$39.00

Manual Included:

- Technical Manual: 202 Pages

Specifications:

- Brand: John Deere

- Model: IV 1200 Series Inboard Planetary Axles

- Type: Planetary Axles

- Manuals: Component Technical Manual

- Publication Numbers: CTM140119

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content (Component Technical Manual CTM140119)

Group 000: Safety

Recognize Safety Information

Handle Fluids Safely—Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Handle Chemical Products Safely

Avoid High-Pressure Fluids

Park Machine Safely

Support Machine Properly

Wear Protective Clothing

Work in Clean Area

Service Machines Safely

Work In Ventilated Area

Illuminate Work Area Safely

Replace Safety Signs

Use Proper Lifting Equipment

Avoid Heating Near Pressurized Fluid Lines

Remove Paint Before Welding or Heating

Use Proper Tools

Construct Dealer-Made Tools Safely

Decommissioning — Proper Recycling and Disposal of Fluids and Components

Live With Safety

Group 005: General

General Inboard Planetary Axle Specifications

Axle Identification

Serial Number Plate

Specification and Configuration Code Plate – 1200 Series

General Repair Procedures

Sealing Instructions

Transmission and Hydraulic Oil

Service and Maintenance Schedule

Check, Drain, and Refill Axle Oil

Alternative and Synthetic Lubricants

Lubricant Storage

Mixing of Lubricants

Grease

Hydraulic Connections

Section 02: Repair and Adjustments

Group 010: Oscillation Assembly

Axle Oscillation Support — Identification

Front Oscillation Support — Installation

Front Oscillation Support — Removal

Rear Oscillation Support — Assemble

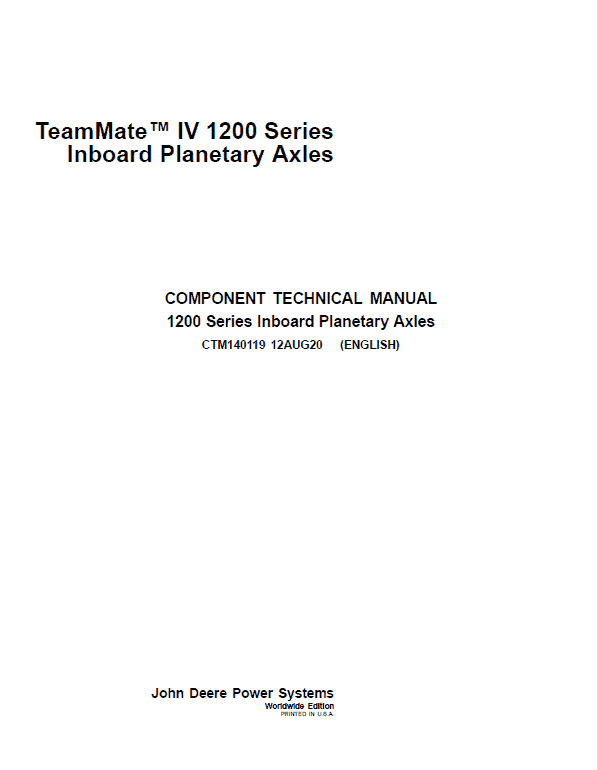

Rear Oscillation Support — Disassemble

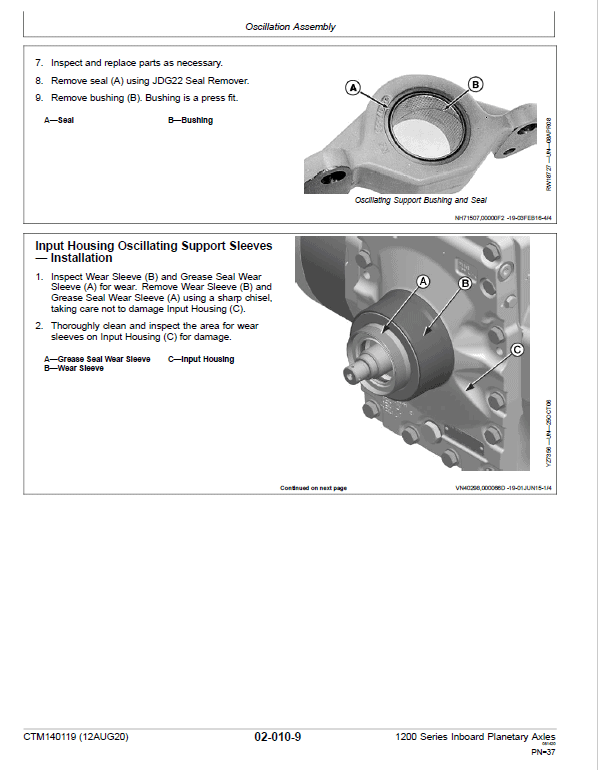

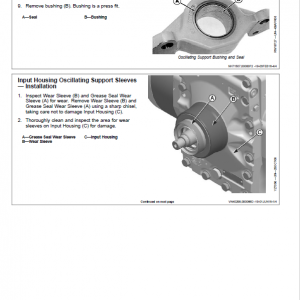

Input Housing Oscillating Support Sleeves — Installation

Oscillating Support — Inspection

Group 020: Axle Repair Stand

Axle Repair Stand — Installation

Axle Repair Stand — Removal

Group 030: Helical Spline Input Housing Assembly

Pinion Shaft and Input Housing Assembly ─ Assembly

Input Yoke — Installation

Input Yoke — Removal

Input Oil and Grease Seal — Installation

Input Oil and Grease Seal — Removal

Input Housing Assembly ─ Assemble

Input Housing Assembly ─ Installation

Input Housing Assembly ─ Removal

Determine Differential Input Shaft Cone Point Shim Pack

Axle Input Housing Assembly — Preload and End Play Adjustment

Axle Input Housing Assembly — End Play Adjustment (In Vehicle)

Group 040: Final Drive Assembly

Axle End and Final Drive Assembly ─ Assembly

Axle End and Final Drive Assemblies ─ Removal

Axle Shaft Bearing — Removal and Installation

Axle Face Seals — Installation

Axle Housing to Axle Shaft — Installation

Axle Bearings — Adjustment

Locking Plate — Installation (Standard Series)

Axle End and Final Drive Assemblies — Installation

Group 050: Planetary Carrier Assembly

Planetary Carrier Assembly — Assembly

Planetary Carrier — Assemble

Planetary Carrier — Inspection

Planetary Carrier — Tear Down

Group 060: Single Disk Service Brake

Single Disk Service Brake — Assembly

Single Disk Service Brake — Assemble

Single Disk Service Brake — Installation

Single Disk Service Brake — Removal

Group 070: Differential Case Assembly

Differential Case Assembly — Assembly

Differential Case Assembly — Removal

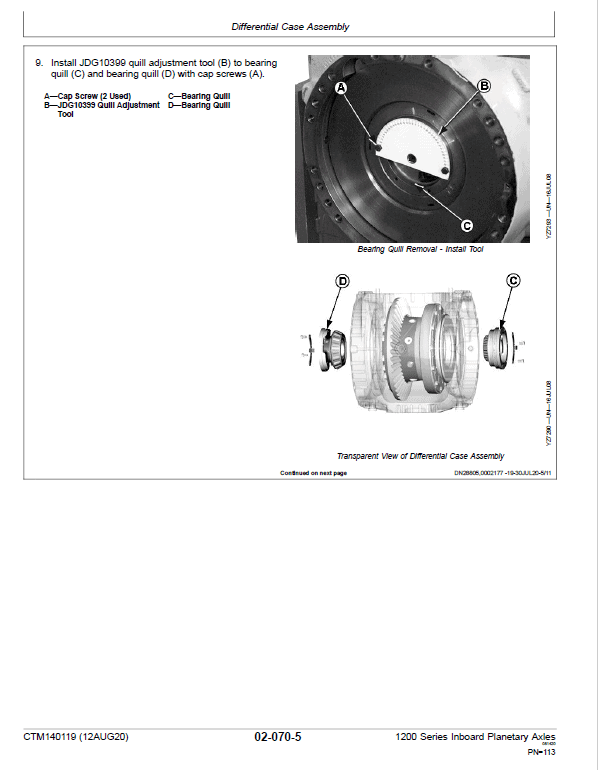

Bearing Quill, Gear Side — Disassemble and Assemble (Without Seals)

Bearing Quill, Opposite Gear Side — Disassemble and Assemble (With Seals)

Differential Assembly ─ Assembly

Differential Assembly — Removal

Differential Locking Clutch — Assemble

Differential Locking Clutch — Teardown

Differential Assembly — Assemble

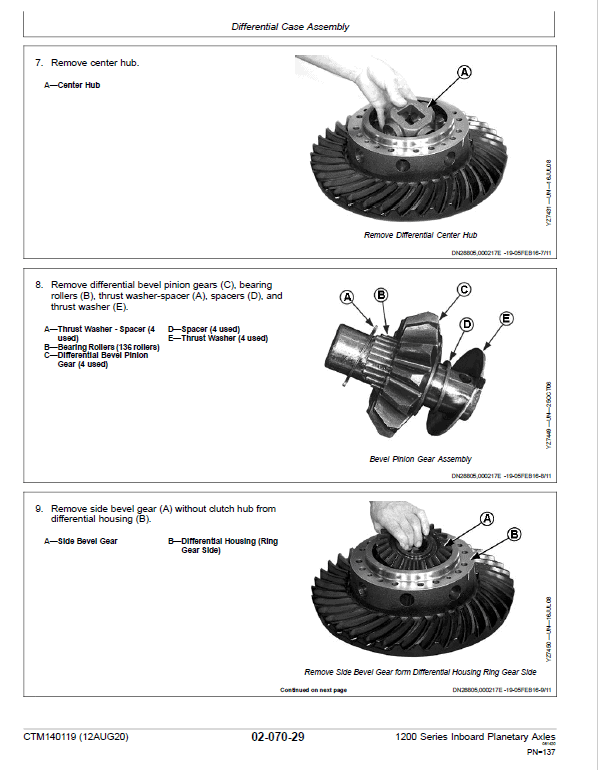

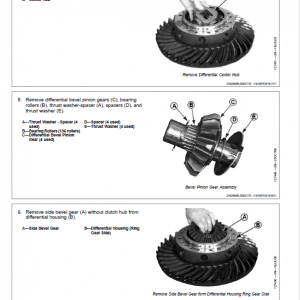

Differential Assembly — Teardown

Differential Ring Gear — Assemble

Differential Ring Gear — Teardown

Differential Case Assembly — Assemble

Differential Assembly — Bearing Preload Adjustment

Differential Assembly — Backlash Adjustment

Section 03: Theory of Operation

Group 100: Axle Operation

Axle Oscillation

Inboard Planetary Axle Operation

Differential Operation

Standard Differential Operation

Dif-Lok Differential Operation

Final Drive – Axle Operation

Service Brake Operation

Section 04: Diagnostics

Group 200: Brake Inspection, Adjustments, Tests, and Bleeding

Brake Disk Inspection (External)

Annular Brake Piston Inspection

Service Brake Leak Test

Group 210: Operational Checks

Axle Vertical Movement Check

Check Carrier Backlash

Check Ring Gear and Pinion Tooth Contact Pattern

Group 220: Differential and Axle Assembly Tests

Air Test Differential Lock (Dif-Lock)

Air Test Axle Assembly

Differential Lock (Dif-Lock) Function Test

Group 230: Troubleshooting

Troubleshoot Axle and Differential

Section 05: Tools and Other Materials

Group 300: Special Tools

Group 310: Other Materials

Other Material

Section 06: Specifications

Group 400: Bolts and Cap Screws Specifications

Metric Bolt and Screw Torque Values

Unified Inch Bolt and Screw Torque Values

Group 410: Sealants and Adhesives Cross-Reference

Sealants and Adhesives Cross-Reference Chart

This component technical manual in conjunction with the machine technical manual. See the-machine technical manual for information on component removal and installation, and gaining access to-the components.

Information is organized in groups for the various components requiring service instruction. At the-beginning of each group are summary listings of all applicable essential tools, service equipment and-tools, other materials needed to do the job, service parts kits, specifications, wear tolerances, and-torque values and covers the recommended repair procedure for the Team Mate™ IV1200 Series Inboard Planetary Axles.

Some from these axles, such as axle housings, brakes, and input quills, may be serviced-without removing the complete axle assembly from the machine. You may have to determine this procedure yourself for a safe removal of such components. See information to remove and install the-complete axle assembly.

Be the first to review “John Deere TeamMate IV 1200 Series Inboard Planetary Axles Component Technical Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.