Description

Table of Contents

Repair Technical Manual (TM14502X019)

Section 00—General Information

Group 0001—Safety

Group 0003—Torque Values

Section 01—Wheels

Group 0110—Powered Wheels and Fastenings

Section 02—Axles and Suspension Systems

Group 0200—Removal and Installation

Group 0225—Input Drive Shafts and U-Joints

Group 0250—Axle Shaft, Bearings, and Reduction Gears

Group 0260—Hydraulic System

Section 03—Transmission

Group 0300—Removal and Installation

Group 0350—Gear, Shafts, and Power Shift Clutches

Group 0360—Hydraulic System

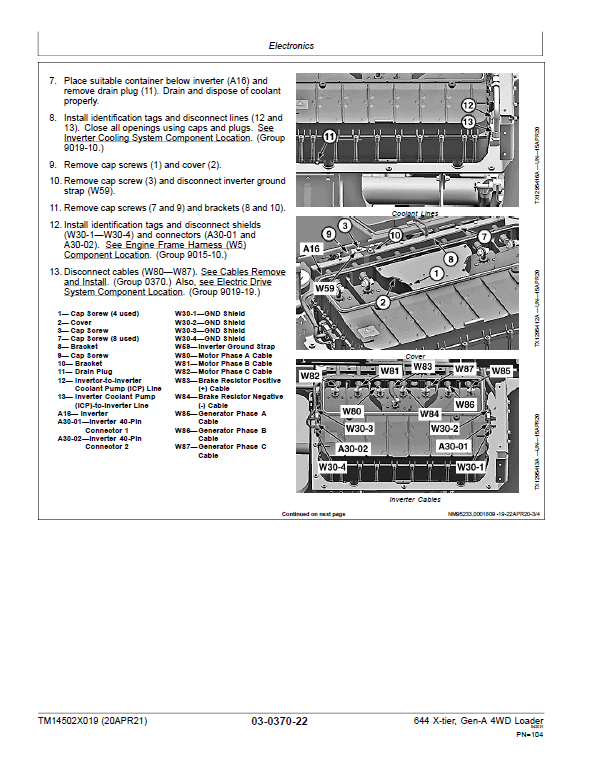

Group 0370—Electronics

Section 04—Engine

Group 0400—Removal and Installation

Section 05—Engine Auxiliary System

Group 0505—Cold Weather Starting Aids

Group 0510—Cooling System

Group 0520—Intake System

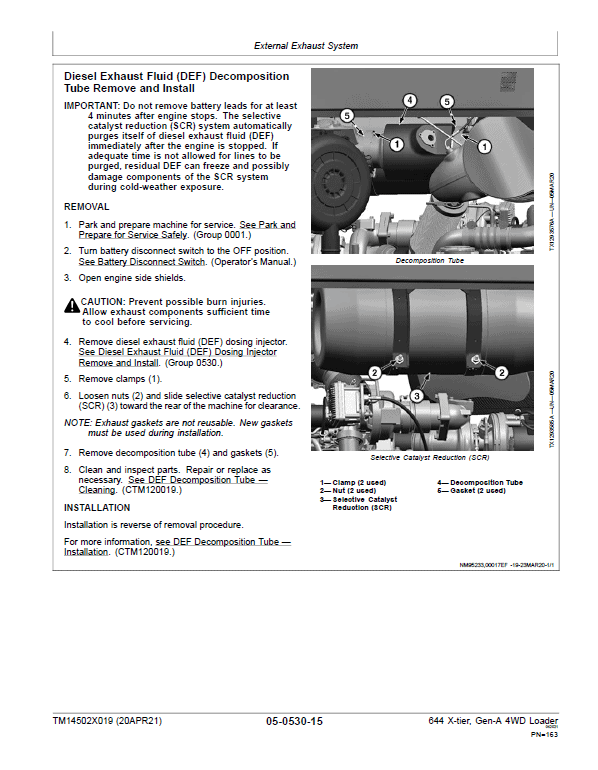

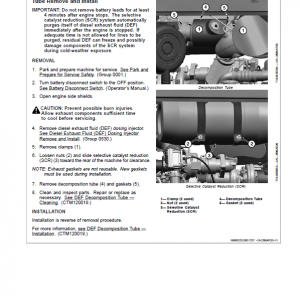

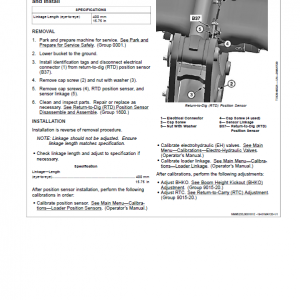

Group 0530—External Exhaust System

Group 0560—External Fuel Supply Systems

Section 07—Damper Drive

Group 0752—Elements

Section 08—Transfer Drive

Group 0841—Housing and Covers

Section 09—Steering System

Group 0960—Hydraulic System

Section 10—Service Brakes

Group 1011—Active Elements

Group 1060—Hydraulic System

Section 11—Park Brake

Group 1111—Active Elements

Group 1160—Hydraulic System

Section 15—Equipment Attaching

Group 1520—Hitches and Hitch Pins

Section 16—Electrical System

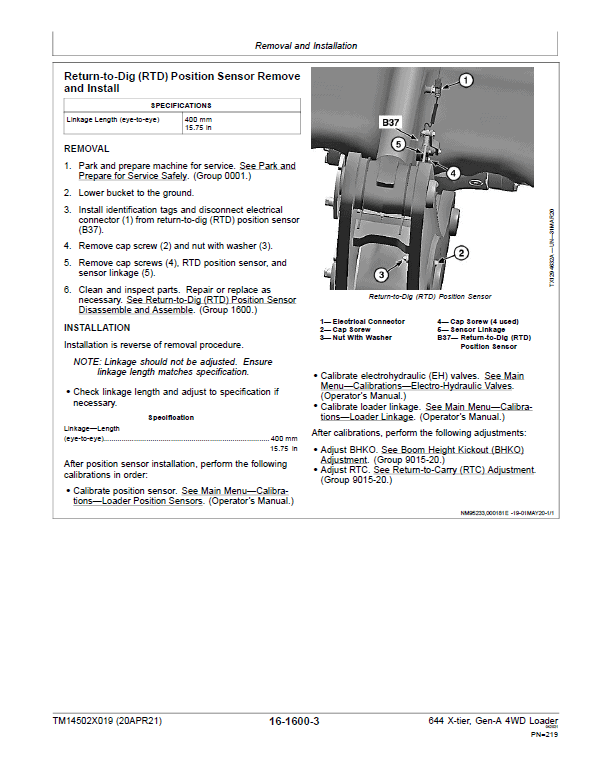

Group 1600—Removal and Installation

Section 17—Frame or Supporting Structure

Group 1740—Frame Installation

Group 1746—Frame Bottom Guards

Group 1749—Chassis Weights

Section 18—Operator’s Station

Group 1800—Removal and Installation

Group 1810—Operator Enclosure

Group 1821—Seat and Seat Belt

Group 1830—Heating and Air Conditioning

Section 19—Sheet Metal and Styling

Group 1910—Hood or Engine Enclosure

Section 31—Loader

Group 3102—Bucket

Group 3140—Frames

Group 3160—Hydraulic System

Section 99—Dealer Fabricated Tools

Group 9900—Dealer Fabricated Tools

Operation and Test Manual (TM14501X019)

Section 9000—General Information

Group 01—Safety

Section 9001—Diagnostic Trouble Codes (DTCs)

Group 10—Engine Control Unit (ECU) Diagnostic Trouble Codes

Group 20—Transmission Control Unit (TCU) Diagnostic Trouble Codes

Group 30—Vehicle Control Unit (VCU) Diagnostic Trouble Codes

Group 40—Sealed Switch Module (SM1) Diagnostic Trouble Codes

Group 50—Automatic Temperature Control (ATC) Diagnostic Trouble Codes

Group 60—Heated/Ventilated Seat (HVS) Diagnostic Trouble Codes

Group 70—Right Joystick 1 (RJ1) Diagnostic Trouble Codes

Group 80—Rotary Switch Module (RSM) Diagnostic Trouble Codes

Group 90—Primary Display Unit (PDU) Diagnostic Trouble Codes

Group 100—Camera Display Unit (VC1) Diagnostic Trouble Codes

Group 110—Vehicle Control 2 (VC2) Diagnostic Trouble Codes

Group 120—Radar Object Detection (ROD) Diagnostic Trouble Codes

Group 130—Ground Speed Radar (RDR) Diagnostic Trouble Codes

Group 140—Joystick Steering Valve (JSV) Diagnostic Trouble Codes

Group 150—Joystick Steering Controller (JSC) Diagnostic Trouble Codes

Group 160—Tire Pressure Monitoring (TPM) System Diagnostic Trouble Codes

Group 170—Motor Inverter 1 (MT1) Diagnostic Trouble Codes

Group 180—Generator Inverter (GN1) Diagnostic Trouble Codes

Section 9005—Operational Checkout Procedure

Group 10—Operational Checkout Procedure

Section 9010—Engine

Group 05—Theory of Operation

Group 10—System Diagrams

Group 25—Tests

Section 9015—Electrical System

Group 05—Theory of Operation

Group 10—System Diagrams

Group 15—Diagnostic Information

Group 16—Monitor Operation

Group 17—Diagnostic Test Box

Group 20—Adjustments

Group 25—Tests

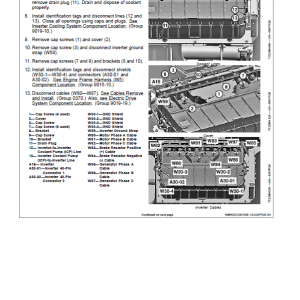

Section 9019—Electric Drive System

Group 05—Theory of Operation

Group 10—System Diagrams

Group 20—Adjustments

Group 25—Tests

Section 9020—Power Train

Group 05—Theory of Operation

Group 10—System Diagrams

Group 15—Diagnostic Information

Group 20—Adjustments

Group 25—Tests

Section 9025—Hydraulic System

Group 05—Theory of Operation

Group 10—System Diagrams

Group 15—Diagnostic Information

Group 20—Adjustments

Group 25—Tests

Section 9031—Heating and Air Conditioning

Group 05—Theory of Operation

Group 10—System Diagrams

Group 15—Diagnostic Information

Group 25—Tests

Read this manual carefully to learn how to operate and service your Loader correctly. Failure to do so could result in personal injury or equipment damage.

Measurements in this manual are given in both metric and customary U.S. unit equivalents. Use only correct replacement parts and fasteners. Metric and inch fasteners may require a specific metric or inch wrench.

These are divided in two parts: Repair and Operation and Tests.

-Repair sections tell how to repair the components.

-Operation and tests sections help you identify the majority of routine failures quickly.

Information is organized in groups for the various components requiring service instruction. At the beginning of each group are summary listings of all applicable essential tools, service equipment and tools, other materials needed to do the job, service parts kits, specifications, wear tolerances, and torque values.

They are concise guides for specific machines and are on-the-job guides containing only the vital information needed for diagnosis, analysis, testing and repair.

Reviews

There are no reviews yet.