John Deere 953G Feller Buncher Service Repair Manual (SN 004001 – 004004)

$42.00

Manual Included:

- Repair Technical Manual: 560 Pages

Specifications:

- Brand: John Deere

- Model: 953G

- Serial Number: (SN 004001 – 004004)

- Type: Feller Buncher

- Manuals: Repair Technical Manual

- Publication Numbers: TM1947

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content

Introduction and Specification

Safety Rules

Power Unit

Brakes Systems

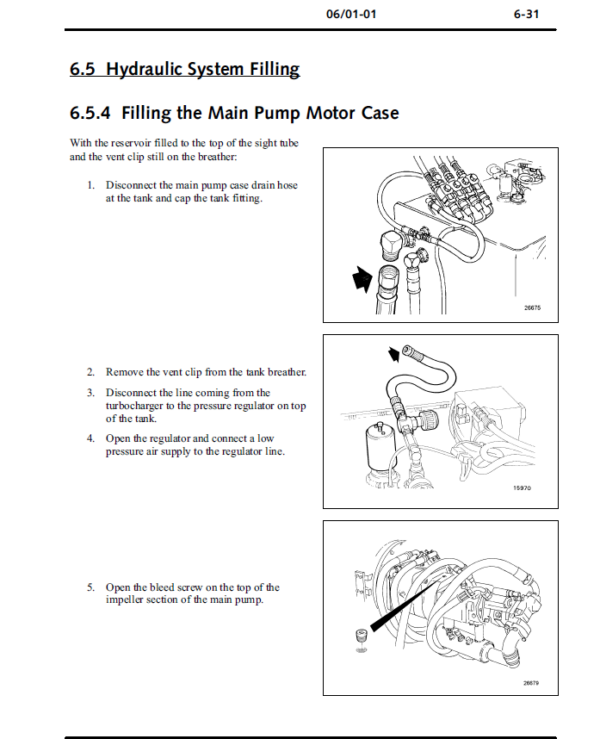

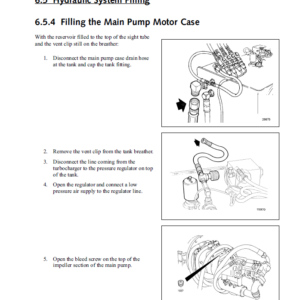

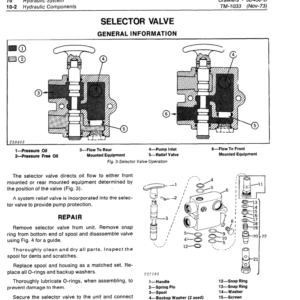

Hydraulic System

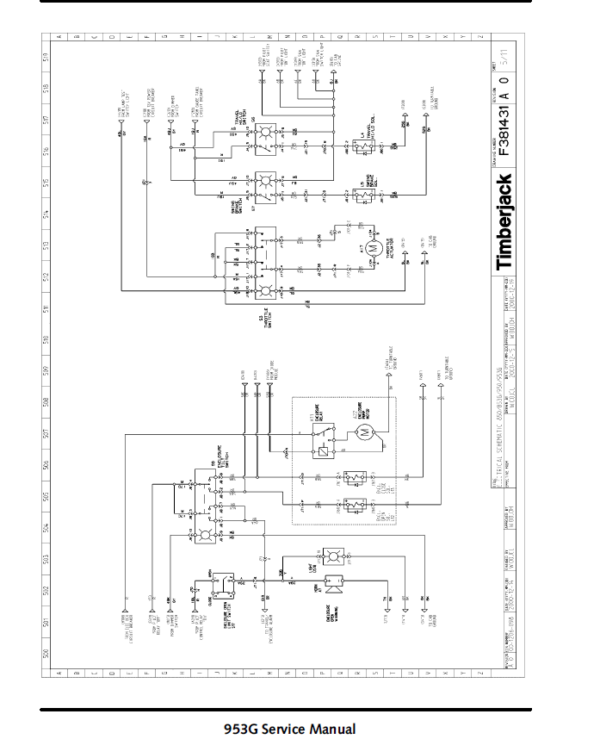

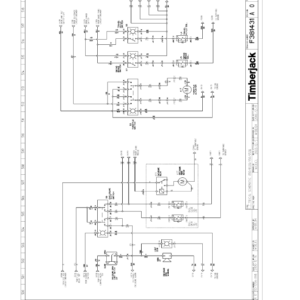

Electrical System

Attachments

Frames

Heating & Air Conditioning

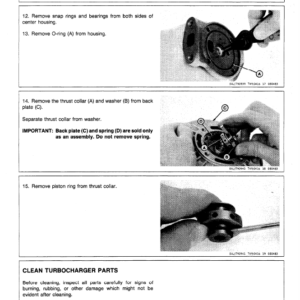

Components are well shielded and have hinged or removable panels to allow for easy access for all routine inspection and servicing by the operator. Service personnel can service or remove small components through these panels. Virtually all external engine servicing and attachment repair or replacement can be completed by opening the top and side hinged engine enclosure doors. This includes the alternator, water pump, starter, A/C compressor, turbocharger, fuel injection pump and injectors. Rear panels allow access to the hydraulic valve compartment, the fuel/water separator and the pumps. A front panel provides access to the radiator, the oil cooler and the air conditioning condenser.

Read the safety messages in the introduction of this manual and the cautions presented throughout the text of the manual.

The John Deere 953G Feller Buncher Repair Manual sections tell how to repair the components and help you identify the majority of routine failures quickly.

Information is organized in groups for the various components requiring service instruction. At the beginning of each group are summary listings of all applicable essential tools, service equipment and tools, other materials needed to do the job, service parts kits, specifications, wear tolerances, and torque values.

Technical Manuals are concise guides for specific machines. They are on-the-job guides containing only the vital information needed for diagnosis, analysis, testing, and repair.

Be the first to review “John Deere 953G Feller Buncher Service Repair Manual (SN 004001 – 004004)”

You must be logged in to post a review.

Reviews

There are no reviews yet.