John Deere X740, X744, X748, X749 John Deere Select and Ultimate Series Tractors Service Repair Manual (TM2350 & TM2351 )

$46.00

Manual Included:

- Repair Technical Manual: 966 pages (TM2350)

- Repair Technical Manual: 1328 Pages (TM2351)

Specifications:

- Brand: John Deere

- Model: X740, X744, X748, X749

- Type: Lawn Tractors

- Manuals: Repair Technical Manual

- Publication Numbers:

North America (with SN after 060001-) – TM2350

Export Edition (Built outside North America) – TM2351 - Language: English

- Format: PDF

- Description

- Additional information

- Reviews (0)

Description

Table of Contents – Technical Manual

Foreword

Safety

Specifications

Engine Diesel

Electrical

Power Train

Hydraulics

Steering

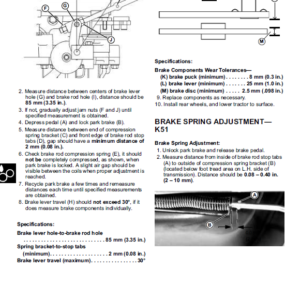

Brakes

Attachments

Miscellaneous

Lawn Tractors Technical manuals are divided in two parts: repair and diagnostics. Repair sections tell how to repair the components. Diagnostic sections help you identify the majority of routine failures quickly.

This manual was planned and written for the Service Department; its place is in the shop. Use the manual whenever in doubt about correct maintenance procedures. Use it as a text book for training new Service Department personnel who are unfamiliar with John Deere Tractors.

They are concise guides for specific-machines and are on-the-job guides-containing only the vital information needed for-diagnosis, analysis, testing, and repair.

Additional information

| Manual | North America (with SN after 060001-) – TM2350, Export Edition (Built outside North America) – TM2351 |

|---|

Be the first to review “John Deere X740, X744, X748, X749 John Deere Select and Ultimate Series Tractors Service Repair Manual (TM2350 & TM2351 )”

You must be logged in to post a review.

Reviews

There are no reviews yet.