John Deere 530B Log Loader Service Repair Manual (F307844 & TMF307844)

Price range: $38.00 through $40.00

Manual Included:

- Technical Manual: 693 Pages (F307844)

- Technical Manual: 674 Pages (TMF307844)

Specifications:

- Brand: John Deere

- Model: 530B

- Serial Number:

TMF307844

SN between WM530BX004300 – WM530BX004307

SN between WM0535X001001 – WM0535X001012

F307844

SN before – WM530BX004299

SN before – WM0535X001000 - Type: Log Loader

- Manuals: Technical Manual

- Publication Numbers: TMF307844 & F307844

- Language: English

- Format: PDF

- Description

- Additional information

- Reviews (0)

Description

Table of Contents ( TMF307844)

– 0010 How To Use This Book

– 1. Component Numbers

– 2. Abbreviations

– 0020 Chapters and Table of Contents

– 1. Chapters

– 2. Table of Contents

– 0030 Foreword and Warranty

– 1. Foreword

– 2. Model and Serial Numbers

– 0040 Safety

– 1. General

– 2. Safety Signs

– 0060 Component Locators

– 1. General Component Locator

– 2. Lower Frame Component Locator

– 3. Upper Frame Component Locator

– 4. Cab Component Locator

– 5. Engine Component Locator

– 6. Hydraulic Component Locator

– 0070 Transporting the Log Loader

– 1. Transporting the Log Loader

– 0080 Repairs

– 1. General Troubleshooting Techniques

– 2. Welding Instructions

– 3. Hydraulic Hoses Inspection and Replacement

– 4. Inspection Check Lists

– 5. Extended Storage

– 1000 Power Unit

– 1. Description and Operation

– 1100 Engine

– 1. Description and Operation

– 2. Engine Specifications

– 3. Engine Oil and Filters

– 4. Checking Belt Tensioner

– 5. Hub Vibration Dampener

– 6. Drive Adapter

– 7. Engine Troubleshooting

– 1300 Engine Mounting

– 1. Engine Mounts Replacement

– 2. Engine Removal and Installation

– 1400 Fuel System

– 1. Description and Operation

– 2. Fuel Tank Removal and Installation

– 3. Fuel Level Sender Replacement

– 4. Fuel Filters

– 5. Bleeding the Fuel System

– 6. Fuel/Water Separator

– 7. Remove Water and Sediment from Tank

– 8. Filling the Fuel Tank

– 9. Fuel System Troubleshooting

– 1500 Cooling System

– 1. Description and Operation

– 2. Specifications

– 3. Coolant Procedures

– 4. Radiator Removal and Installation

– 5. Testing and Maintaining the Cooling System

– 6. Cooling System Troubleshooting

– 1700 Air Intake System

– 1. Description and Operation

– 2. Air Filters 2.1 Changing Air Filters

– 1800 Exhaust System

– 1. Description and Operation

– 2. Exhaust System Removal and Installation

– 2000 Hydraulics

– 1. Hydraulic System Description and Operation

– 2. Hydraulic System Specifications

– 3. Hydraulic System Pressure Tests and Adjustments

– 4. Bleeding the Hydraulic System

– 5. Hydraulic Component Schematic Symbols

– 6. Hydraulic Schematic

– 7. Hydraulic System Troubleshooting

– 2110 Main Pump

– 1. Description and Operation

– 2. Main Pump Specifications

– 3. Main Pump Removal and Installation

– 4. Main Pump Servicing

– 5. Pump Delivery Test

– 6. Main Pump Troubleshooting

– 2130 Pilot Pump

– 1. Description and Operation

– 2. Pilot Inline Filter

– 3. Pilot Pump and Filter Specifications

– 4. Pilot Pump Removal and Installation

– 5. Pilot Pump Servicing

– 6. Pilot Pump Startup

– 7. Pilot Pump Troubleshooting

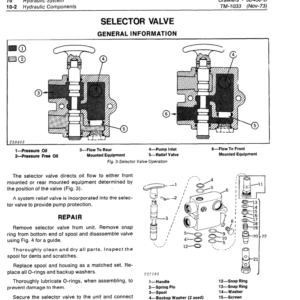

– 2400 Valves

– 1. Valves Locator

– 2. General Servicing Notes

– 3. Valves

– 2410 Loader Control Valves

– 1. Description and Operation

– 2. Control Valves Specifications

– 3. Control Valves Removal and Installation

– 4. Control Valve Servicing

– 5. Pilot Operated Spool Section Repair

– 6. Solenoid Operated Spool Section Repair

– 7. Relief Valve Repair

– 8. Control Valves Troubleshooting

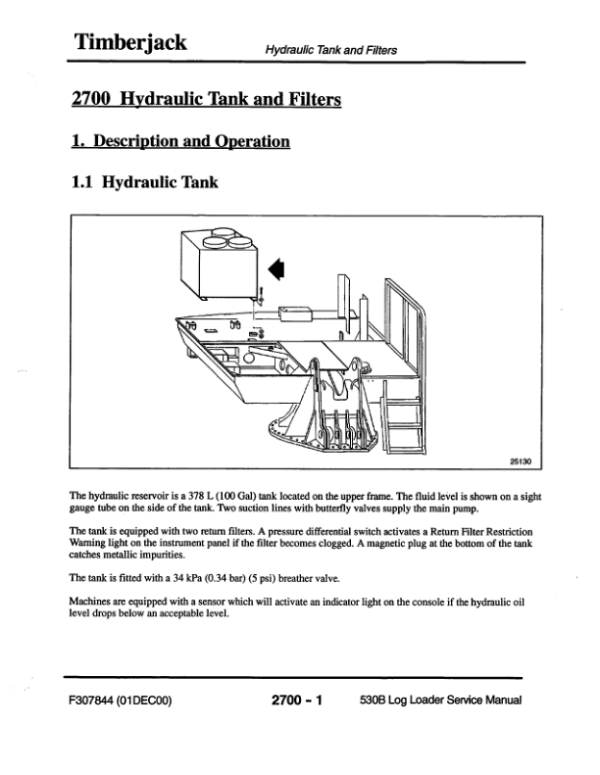

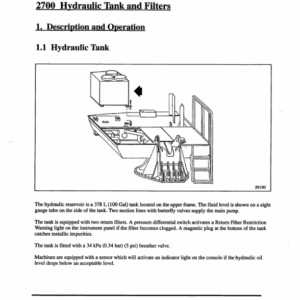

– 2700 Hydraulic Tank and Filters

– 1. Description and Operation

– 2. Tank and Filters Specifications

– 3. Hydraulic Tank and Filter Servicing Notes

– 4. Hydraulic Filters Replacement

– 5. Hydraulic Tank Removal and Installation

– 2800 Cylinders

– 1. Main Boom and Jib Boom Cylinder Servicing

– 2. Stabilizer Cylinders Servicing

– 3. Cylinder Troubleshooting

– 2850 Swing Motor

– 1. Description and Operation

– 2. Swing Motor Specifications

– 3. Swing Motor Removal and Installation

– 4. Swing Motor Servicing

– 2910 Swivel Rotary Manifold

– 1. Description and Operation

– 2. Swivel Rotary Manifold Removal and Installation

– 3. Swivel Rotary Manifold Servicing

– 4. Swivel Rotary Manifold Troubleshooting

– 2940 Tilt Pump and Filler Pump

– 1. Engine Enclosure Tilt System

– 2. Filler Pump

– 2950 Hydraulic Cooling

– 1. Description and Operation

– 2. Hydraulic Cooler Specifications

– 3. Oil Cooler Removal and Installation

– 4. Hydraulic Cooling Troubleshooting

– 3000 Electrical

– 1. Description and Operation

– 2. Electrical Specifications

– 3. Circuit Descriptions

– 4. Harnesses

– 5. Electrical Schematics

– 6. Electrical Troubleshooting

– 3200 Wiring Harness

– 1. General

– 2. Wiring Harness Repair Procedures

– 3910 Electrical Testing

– 1. Circuit Testing

– 2. Circuit Malfunctions Summary

– 5000 Cab

– 1. General

– 2. Operator’s Seat

– 3. Cab Electrical Equipment

– 4. Cab Environment

– 5120 Cab Mounting

– 1. Description and Operation

– 2. Cab Mount Replacement

– 3. Cab Removal and Installation

– 5160 Windows

– 1. Description and Operation

– 2. Servicing the Wipers

– 3. Cleaning the Windows

– 5200 Seat

– 1. Description and Operation

– 2. Seat Belt Inspection

– 3. Armrest Joystick Controls

– 5500 Heater/Air Conditioner Unit

– 1. Description and Operation

– 2. Air Conditioner Safety Precautions

– 3. Inspecting the A/C System

– 4. Heater/Air Conditioner Troubleshooting

– 6000 Frames

– 1. Description and Operation

– 2. Installation of Loader on Trailer

– 6600 Swing Drive

– 1. Swing Drive

– 6610 Swing Gear Box

– 1. Description and Operation

– 2. Swing Gear Box Specifications

– 3. Checking & Changing Gearbox Oil

– 4. Gearbox Removal and Installation

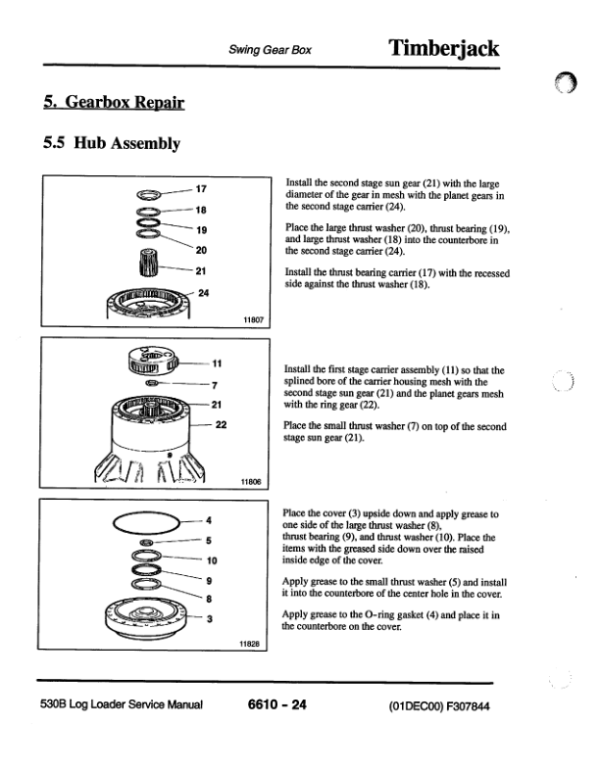

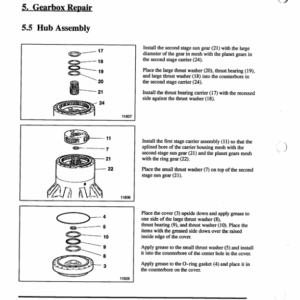

– 5. Gearbox Repair

– 6. Gearbox Servicing Special Tools

– 6620 Swing Bearing

– 1. Swing Bearing Replacement

– 6800 Stabilizers

– 1. Description and Operation

– 2. Stabilizer Cylinder Removal and Installation

– 3. Stabilizer Removal and Installation

– 7000 Loader

– 1. Description and Operation

– 2. Precautions

– 3. Loader Servicing

– 4. Loader Lubrication

– 5. No Power Boom Lowering

– 6. Grapple Removal and Installation

– 7. Jib Boom Cylinder Removal and Installation

– 8. Main Boom Cylinder Removal and Installation

– 9. Jib Boom Removal and Installation

– 10. Main Boom Removal and Installation

– 11. Heel Bar Installation

– 9500 Torque Values

– 1. Fastener Torque Values

– 2. Hydraulic Fitting Torque Values

– 9600 Measurement Conversion Tables

– 1. Measurement Conversion Tables

– 2. Metric and Imperial Unit Expressions

– 3. Wood Measurement Equivalents

– 4. Weights of Commercially Important Woods

– 9800 General Machine Specifications

– 1. Machine Dimensions

– 2. Technical Specifications

– 3. Fluids and Lubricants

– Appendix A

– A–1 Lubrication & Maintenance

– A–2 Hydraulic System

– A–3 Electrical System

– A–4 Troubleshooting

– Appendix B

– B–1 Lubrication & Maintenance

– B–2 Hydraulic System

– B–3 Electrical System

– B–4 Troubleshooting

This manual is for a technician and contains sections that are only for this Log loader model. This sections tells how to repair the components. Diagnostic sections help you identify the majority of routine failures quickly. Information is in groups for the various components requiring service instruction. At the beginning of each group are summary listings of all applicable essential tools, service equipment and tools, other materials needed to do the job, service parts kits, specifications, wear tolerances, and torque values.

Additional information

| Publication | F307844, TMF307844 |

|---|

Be the first to review “John Deere 530B Log Loader Service Repair Manual (F307844 & TMF307844)”

You must be logged in to post a review.

Reviews

There are no reviews yet.