Description

Table of Contents:

Repair Technical Manual – TM11407

Section 00—General Information

Group 0001—Safety

Group 0003—Torque Values

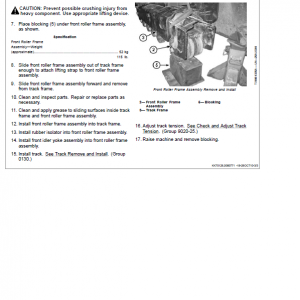

Section 01—Wheels or Tracks

Group 0110—Powered Wheels and Fastenings

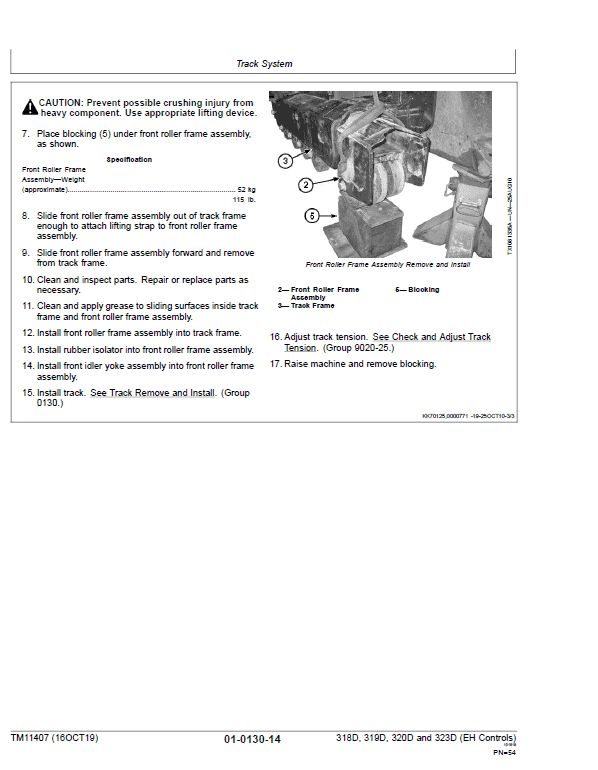

Group 0130—Track System

Section 02—Axles and Suspension Systems

Group 0201—Drive Axle Housing and Support

Group 0250—Axle Shaft, Bearings, and Reduction Gears

Section 03—Transmission

Group 0315—Controls Linkage

Group 0325—Flywheel Coupler

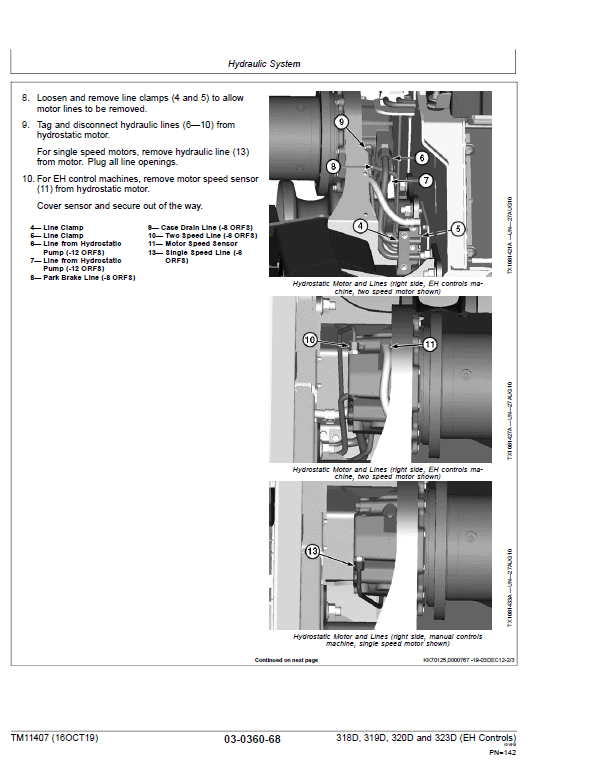

Group 0360—Hydraulic System

Section 04—Engine

Group 0400—Removal and Installation

Section 05—Engine Auxiliary System

Group 0510—Cooling Systems

Group 0520—Intake System

Group 0530—External Exhaust Systems

Group 0560—External Fuel Supply Systems

Section 17—Frame or Supporting Structure

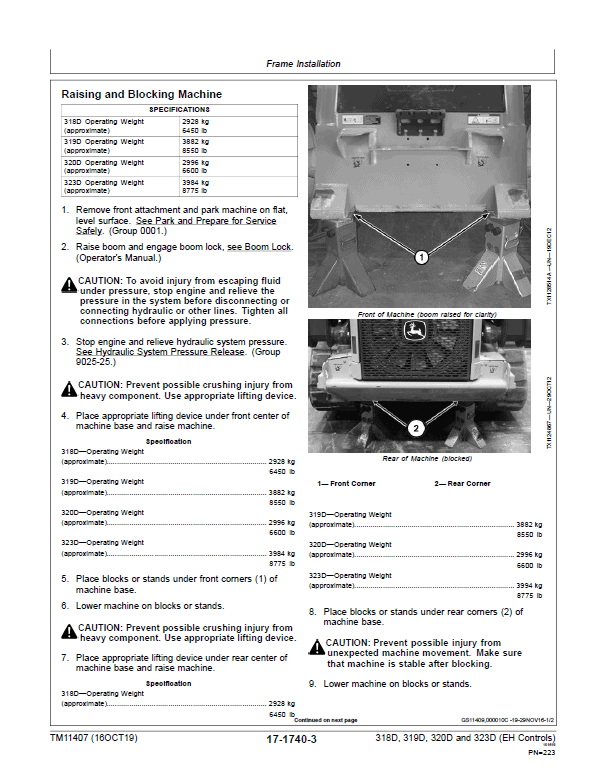

Group 1740—Frame Installation

Section 18—Operator’s Station

Group 1800—Removal and Installation

Group 1810—Operator Enclosure

Group 1821—Seat and Seat Belt

Group 1830—Heating and Air Conditioning

Section 19—Sheet Metal and Styling

Group 1910—Hood or Engine Enclosure

Section 20—Safety and Convenience

Group 2001—Radio

Section 21—Main Hydraulic System

Group 2160—Hydraulic System

Section 31—Loader

Group 3104—Attachment Coupler

Group 3140—Frame

Group 3160—Hydraulic System

Section 99—Dealer Fabricated Tools

Group 9900—Dealer Fabricated Tools

Operation and Test Manual – TM11406

Section 9000—General Information

Group 01—Safety

Section 9001—Diagnostic Trouble Codes (DTCs)

Group 10—Engine Control Unit (ECU) Diagnostic Trouble Codes

Group 20—Engagement and Monitor Unit (EMU) Diagnostic Trouble Codes

Group 30—Hydraulic Control Unit (HCU) Diagnostic Trouble Codes

Group 40—Left Joystick Controller (JSL)

Group 50—Right Joystick Controller (JSR)

Section 9005—Operational Checkout Procedure

Group 10—Operational Checkout Procedure

Section 9010—Engine

Group 05—Theory of Operation

Group 15—Diagnostic Information

Group 25—Tests

Section 9015—Electrical System

Group 05—System Information

Group 10—System Diagrams

Group 15—Sub-System Diagnostics

Group 16—Monitor Operation

Group 20—References

Section 9020—Power Train

Group 05—Theory of Operation

Group 15—Diagnostic Information

Group 25—Tests

Section 9025—Hydraulic System

Group 05—Theory of Operation

Group 15—Diagnostic Information

Group 25—Tests

Section 9026—Hydrostatic System

Group 05—Theory of Operation

Group 15—Diagnostic Information

Group 25—Tests

Section 9031—Heating and Air Conditioning

Group 05—Theory of Operation

Group 15—Diagnostic Information

Group 25—Tests

Section 9900—Dealer Fabricated Tools

Group 99—Dealer Fabricated Tools

Read this to learn how to operate and service your Skid Steer correctly. Failure to do so could result in personal injury or equipment damage.

The John Deere 318D, 320D (EH Controls) Skid Steer Loader Technical manuals are divided in two parts: Repair and Operation and Tests.

-Repair sections tell how to repair the components.

-Operation and tests sections help you identify the majority of routine failures quickly.

Choosing the Correct Supporting Manuals

They are available in different machine configurations based on the various markets into which they are sold. Different supporting manuals exist for different machine configurations. When necessary, product identification numbers are listed on the front covers of skid steer manuals as shown on the pictures. These numbers are used to identify the correct supporting manual for the machine.

These are concise guides for specific machines. They are on-the-job guides containing only the vital information needed for diagnosis, analysis, testing and repair.

Reviews

There are no reviews yet.