John Deere 310G Backhoe Loader Service Repair Manual

$52.00

Manual Included:

- Technical Manual: 724 Pages (TM1886)

- Operation and Test Manual: 854 Pages (TM1885)

Specifications:

- Brand: John Deere

- Model: 310G

- Type: Loader

- Manuals: Repair Technical and Operation and Test Manual

- Publication Numbers: TM1886 and TM1885

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Contents

Repair Technical Manual (TM1886)

Operation and Test Manual (TM1885)

MEASUREMENTS in this manual are given in both metric and customary U.S. unit equivalents. Use only correct replacement parts and fasteners. Metric and inch fasteners may require a specific metric or inch wrench.

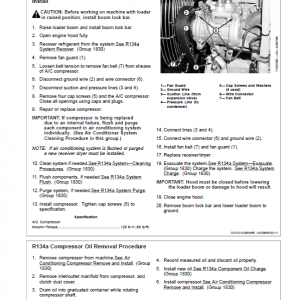

The Technical manuals are divided in two parts: Repair and Operation and Tests.

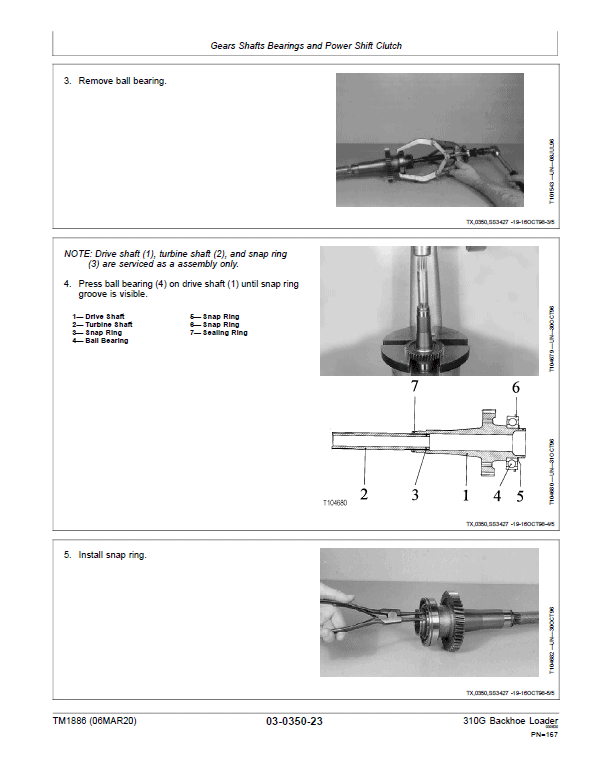

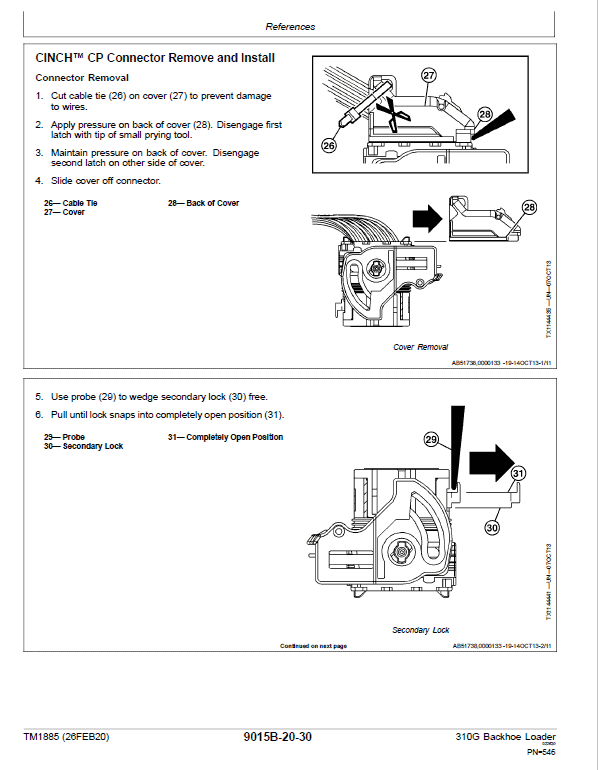

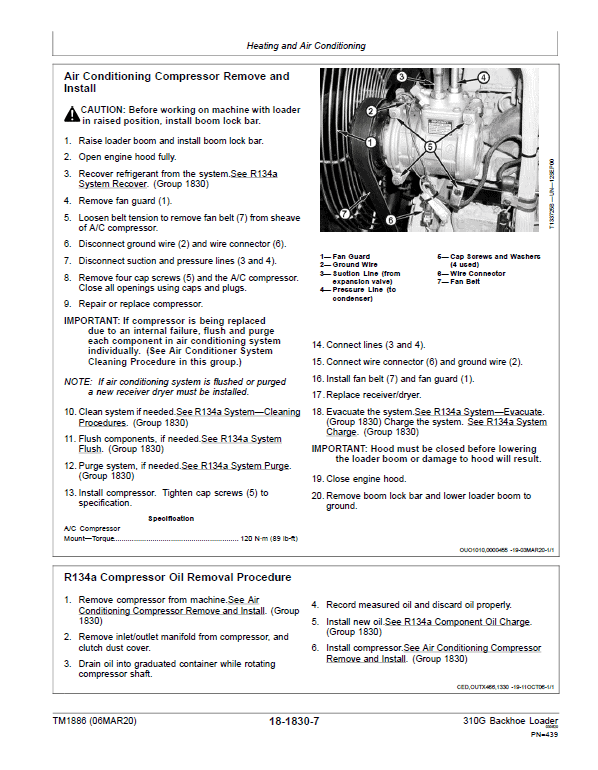

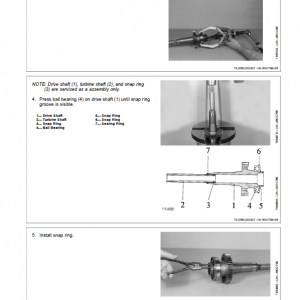

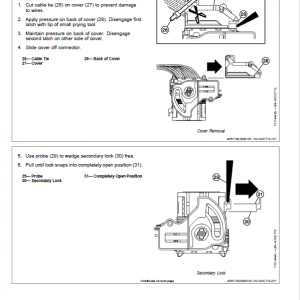

-Repair sections tell how to repair the components.

-Operation and tests sections help you identify the majority of routine failures quickly.

Please remember, the operator is the key to preventing accidents.

1. Headlights/Taillights. Two front halogen driving/work lights and two rear halogen work lights.

2. Signal/Warning Lights. Roof mounted turning signal lights and warning lights for on-road use.

3. ROPS Protection. Certified rollover protection structure surrounds the operator. Integral roof provides overhead protection.

4. Seat Position Sensor. An audio/visual warning alerts operator when FNR is in forward/reverse and the seat turned toward the backhoe position.

5. Interior Rear view Mirror. Offers the operator a view of activity behind him.

6. Handholds. Large and conveniently placed, make it easy to enter or exit the operator’s station.

7. Loader Boom Service Lock. Provided for working on or around this machine with the boom raised.

8. Engine Fan Guard. A secondary engine fan guard inside engine compartment encloses rotating fan blades.

9. Bypass Start Protection. Shielding over the starter solenoid helps prevent dangerous bypass starting.

10. Ground-Level Fuelling, Daily Service Checks.

Ground-level fuelling feature eliminates the need to climb on the machine to fuel it.

11. Steps. Wide, skid-resistant steps provide excellent footing for getting in/out of operator’s station.

12. Independent Parking/Secondary Brake.

Independent, electrically controlled, parking brake electrically engages when the engine is stopped.

13. Neutral Start. Prevents the engine from being started unless FNR control is in neutral.

14. Backup Alarm. Alerts bystanders when the machine is shifted into reverse.

15. Seat Belt Retractors. Seatbelt retractors help keep belts clean and convenient to use.

16. Exceptional Visibility. Views to either side and front or rear working tools are unrestricted.

17. Operator Manual Holder. A sealed manual holder keeps manual clean and dry.

Be the first to review “John Deere 310G Backhoe Loader Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.