Description

Table of Contents

Repair Technical Manual – TM13097x19

Section 00—General Information

Group 0001—Safety

Group 0003—Torque Values

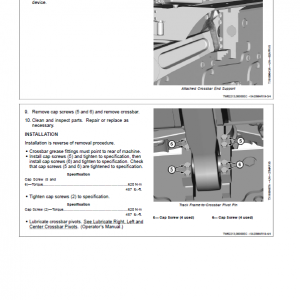

Section 01—Tracks

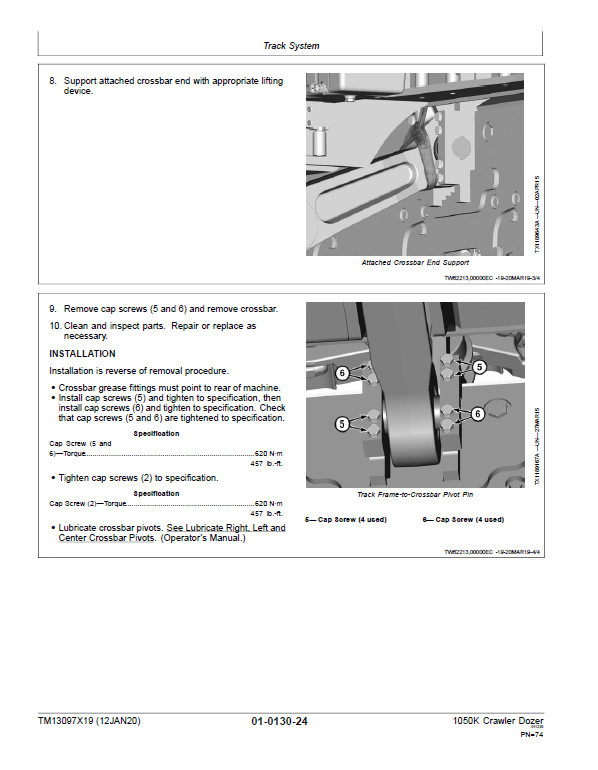

Group 0130—Track System

Section 02—Axles and Suspension Systems

Group 0201—Drive Axle Housing and Support

Group 0250—Axle Shaft, Bearings, and Reduction Gears

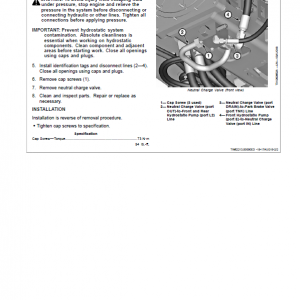

Group 0260—Hydraulic System

Section 03—Transmission

Group 0300—Removal and Installation

Group 0315—Controls Linkage

Group 0325—Input Drive Shafts and U-Joints

Group 0360—Hydraulic System

Section 04—Engine

Group 0400—Removal and Installation

Section 05—Engine Auxiliary System

Group 0505—Cold Weather Starting Aids

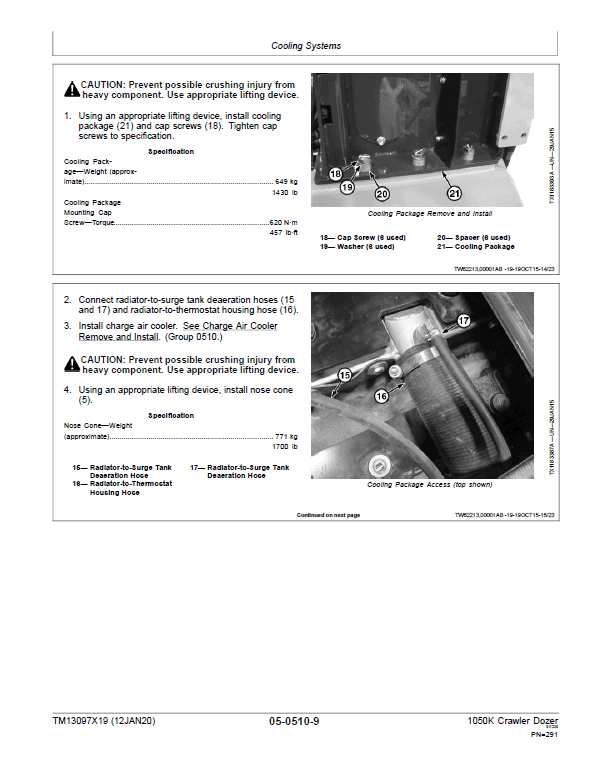

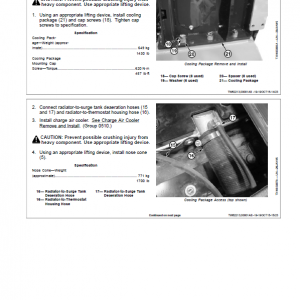

Group 0510—Cooling Systems

Group 0520—Intake System

Group 0530—External Exhaust Systems

Group 0560—External Fuel Supply Systems

Section 11—Park Brake

Group 1100—Removal and Installation

Group 1115—Controls Linkage

Group 1160—Hydraulic System

Section 15—Equipment Attaching

Group 1511—Drawbar

Section 16—Electrical System

Group 1600—Removal and Installation

Section 17—Frame or Supporting Structure

Group 1740—Frame Installation

Group 1746—Frame Bottom Guards

Group 1749—Chassis Weights

Section 18—Operator’s Station

Group 1800—Removal and Installation

Group 1810—Operator Enclosure

Group 1821—Seat and Seat Belt

Group 1830—Heating and Air Conditioning

Section 19—Sheet Metal and Styling

Group 1910—Hood or Engine Enclosure

Group 1921—Grille and Grille Housing

Section 20—Safety and Convenience

Group 2004—Horn and Warning Devices

Section 21—Main Hydraulic System

Group 2160—Hydraulic System

Section 32—Bulldozer

Group 3201—Blade

Group 3240—Frames

Group 3260—Hydraulic System

Section 42—Ground Conditioning Tool

Group 4200—Ripper Remove and Install—If Equipped

Group 4201—Blades, Teeth, and Shanks

Group 4260—Hydraulic System

Section 99—Dealer Fabricated Tools

Group 9900—Dealer Fabricated Tools

Operation and Test Manual – TM13096x19

Section 9000—General Information

Group 01—Safety

Section 9001—Diagnostic Trouble Codes (DTCs)

Group 01—General Information

Group 10—Engine Control Unit (ECU) Diagnostic Trouble Codes

Group 20—Display Menu Handler (DMH) Diagnostic Trouble Codes

Group 30—Sealed Switch Module (SSM) Diagnostic Trouble Codes

Group 40—Transmission Control Unit (TCU) Diagnostic Trouble Codes

Group 50—Vehicle Control Unit (VCU) Diagnostic Trouble Codes

Group 60—Hydraulic Valve Controller (HVC) Diagnostic Trouble Codes

Group 70—Blade Control Joystick (BCJ) Diagnostic Trouble Codes

Section 9005—Operational Checkout Procedure

Group 10—Operational Checkout Procedure

Section 9010—Engine

Group 05—Theory of Operation

Group 10—System Diagrams

Group 15—Diagnostic Information

Group 20—Adjustments

Group 25—Tests

Section 9015—Electrical System

Group 05—Theory of Operation

Group 10—System Diagrams

Group 15—Diagnostic Information

Group 16—Display Unit Operation

Group 17—Diagnostic Test Box

Group 18—Topcon® Integrated Grade Control (IGC)

Operation (Factory Installation)

Group 20—Adjustments

Group 25—Tests

Section 9020—Power Train

Group 05—Theory of Operation

Group 10—System Diagrams

Group 15—Diagnostic Information

Section 9025—Hydraulic System

Group 05—Theory of Operation

Group 10—System Diagrams

Group 15—Diagnostic Information

Group 25—Tests

Section 9026—Hydrostatic System

Group 05—Theory of Operation

Group 10—System Diagrams

Group 15—Diagnostic Information

Group 25—Tests

Section 9031—Heating and Air Conditioning

Group 05—Theory of Operation

Group 10—System Diagrams

Group 15—Diagnostic Information

Group 25—Tests

Section 9900—Dealer Fabricated Tools

Group 99—Dealer Fabricated Tools

This manual is written for an experienced technician and Owners. Essential tools required in performing certain service work are identified in this manual and are recommended for use. Read the safety messages in the introduction of this manual and the cautions presented throughout the text of the manual.

These are divided in two parts: Repair and Operation and Tests.

-Repair sections tell how to repair the components.

-Operation and tests sections help you identify the majority of routine failures quickly.

Information is organized in groups for the various components requiring service instruction. At the beginning of each group are summary listings of all applicable essential tools, service equipment and tools, other materials needed to do the job, service parts kits, specifications, wear tolerances, and torque values.

They are concise guides for specific machines. They are on-the-job guides containing only the vital information needed for diagnosis, analysis, testing and repair.

Reviews

There are no reviews yet.