John Deere 1000, 1700, 4000 Series Long and Short Drop Powershift Transmission Component Technical Manual (CTM202 & 4005057)

$27.00

Manual Included:

- Component Technical Manual: 146 Pages & 56 Pages

Specifications:

- Brand: John Deere

- Model: 1000, 1700, 4000 Series

- Type: Powershift Transmission (PST)

- Manuals: Component Technical Manual

- Publication Numbers: CTM202 and 4005057

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

Table of Content (Component Technical Manual CTM202)

Powershift Transmissions

Group 05—Safety

Group 10—General Information

Group 15—1000 And 1700 Series Transmission

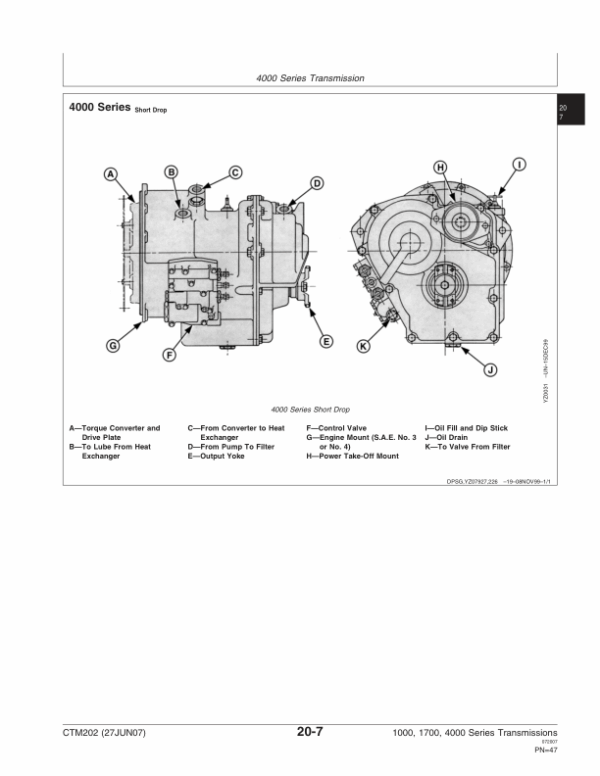

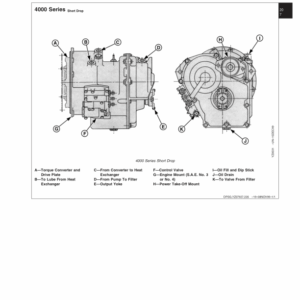

Group 20—4000 Series Transmission

The 4000, 1700 and 1000 series powershift transmissions all operate on the same principle, the difference being the horsepower rating. However, the 4000 series, having a different pump and valve body, has different pressure ranges that are described in a separate section.

The 1000, and 1700 series are forward and reverse transmissions, with the option of 3, 4 or 6 speeds in either direction. Forward motion, reverse motion, and the speeds are obtained through the use of hydraulically actuated multiple disc clutches. These clutches are power absorbing members that can be engaged at full engine power. Shifting under full engine power makes these models a full power shift for the forward and reverse motion in all speeds.

The clutches in these units are hydraulically applied and spring released. Because the clutches are hydraulically controlled, there is automatic compensation for normal wear, which eliminates the need for adjustment. Each clutch has paper graphitic friction plates and polished steel reaction plates.

The power from the engine is transmitted to the transmission through a torque converter. The use of the torque converter has two distinct advantages; (1) The converter is essentially a fluid drive, there being no direct mechanical connection through it. This feature creates a very smooth and shock-free drive eliminating engine stalling and lugging. (2) The converter multiplies torque during heavy pull-down loads. When loads are light, the converter transmits the engine power directly at almost engine speeds, and there is no torque multiplication. The net result is an action like a transmission, with infinitely variable and automatic speed ratios. The need for shifting gears, although present, is greatly reduce

Table of Content (Component Technical Manual 4005057 – Covering 1000 Series only)

Parts Ordering Instructions

Description

Service and Oil Recommendations

Bolt Torque Specifications

Trouble Shooting

Control Valve, Function and Pressure Check

Converter Installation, Remote Filter and

Heat Exchanger Data

Clutch and Stage Locations

Oil Flow Circuit 9 5/8 Drop

Oil Flow Circuit 18 5/8 Drop

Special Tools

Converter, 11 3A

Converter, 12 3/4

Control Valve, 3-Speed

Control Valve, 4-Speed

Control Valve with Feathering In Lo Gear

Brake Cutoff Valve

Primary Pump With Transmission Mounted Oil Filter

Primary Pump With Auxiliary Drive

Front Cover Assembly

Clutch Stack Assembly

Main Case, 9 5/8 Drop

Brake, Drum Type

Main Case, 18 5/8 Drop

Hi-Lo Range Shift

Output Bearing Retainer Shim Adjustment

Converter, Midship Mounted

The Series 1000 Shift-O-Matic Drive is a forward and reverse transmission, with the option of 2, 3, 4 or 6 speedy in either direction. Forward motion, reverse motion, and the four speeds are obtained through the use of hydraulically actuated multiple disc clutches. These clutches are power absorbing members that can be engaged at full engine power. Shifting under full engine power makes this model a full power shift for the forward and reverse motion in all four speeds.

The clutches in this unit are hydraulically applied and spring released. Because the clutches are hydraulically controlled, there is automatic compensation for normal wear, which eliminates the need for adjustment. Each clutch uses eleven semi metallic friction plates, and eleven polished steel reaction plates, except for the high gear clutch that uses eight of each plate.

The power from the engine is transmitted to the Shift-O-Matic^ through a torque converter. The use of the torque converter has two distinct advantages, one is the converter is essentially a fluid drive, there being no direct mechanical connection through it. This feature creates a very smooth and shock free drive eliminating engine stalling and lugging. A second advantage is that the converter multiplies torque during heavy pull-down loads. When loads are light the converter transmits the engine power directly at almost engine speed, and there is no torque multiplication. The net result is an action like a transmission, with infinitely variable and automatic speed ratios. The need for shifting gears, although present, is greatly reduced.

Be the first to review “John Deere 1000, 1700, 4000 Series Long and Short Drop Powershift Transmission Component Technical Manual (CTM202 & 4005057)”

You must be logged in to post a review.

Reviews

There are no reviews yet.