Hyundai HA30, HA30A, HA45, HA45A Articulated Dump Truck Service Repair Manual

$38.00

Manual Included:

- Service Repair Manual: 1133 pages

- Operators Manual: 284 Pages

Specifications:

- Brand: Hyundai

- Model:HA30, HA30A, HA45, HA45A

- Type: Articulated Dump Truck

- Manuals: Service Repair and Operators Manual

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

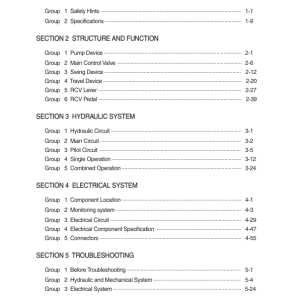

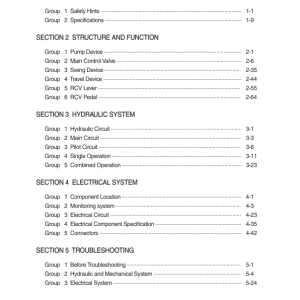

Table of Contents:

Foreword

Doosan ADT Payload Policy

Torque limit table

Types of sealing-/locking compounds and lubricants

Safety in workshop

Working on machine

Personal Protective Equipment (PPE)

Vibration

Injurious noise

Organic solvent

Fuelling

Fire and Explosion Prevention

Fire and explosion risks

In case of Fire

Coolant

Refrigerant

Air pollution

Operation in extreme conditions

Liquid or gas under high pressure

Asbestos

Lead

Battery hazard prevention

Disposal of hazardous materials

Jacked up vehicle or bodywork

Crushing and Cutting Danger

Heavy units

More than one person working with the same object

Involuntary start of electric motors etc.

Rotating parts

Splinters, flying object When using certain tools

Springs under load

Precautions for disassembly and assembly

HA30 – HA45 Final S2 – 1 Engine PDE (VERKST-BOK – 1132510 – 1 – A)

Engine identification

Removal of engine assembly

Lifting the engine

Starting the engine

Important information about the fuel

Fuel system Tier2 (PDE)

Schematic diagram of the fuel system Tier2

Overflow valve

General

Fuel

Temperature dependency of the fuel

Fuel filter

Changing the fuel filter

Water separating prefilter PDE

Changing the water separating fuel filter

Bleeding the fuel system

Feed pump

Renewing the control unit

Cylinder head – PDE System Tier2

Cylinder head, parts view. PDE Tier2

Special tools

Valve mechanism

Dismantling

Renewing the valve stem seal

Replacement of valve seats

Machining the valve seats insert

Renewing the valve guides

Renewing PDE unit injector sleeves

Assembly

Fitting

Valve adjustment DC9 / DC13 with XPI

Adjustment tables DC9 / DC13

Checking and adjusting the unit injectors

Turbocharger

Measuring radial clearance and axial clearance

Renewing the turbocharger

General

Changing oil filter

Oil analysis

Checking oil level

Changing the oil

Special tools

Pistons and cylinder liners

Special tools

Connecting rods

Removing and dismantling connecting rods and pistons

Renewal of bearing bushing in connecting rod

Pistons

Assembling piston and connecting rod

Cylinder block

Cylinder liner

Removing the cylinder liners

Measuring the cylinder liner height

Measuring the cylinder wear ridge and cylinder bore

Fitting the cylinder liners

Fitting the piston and connecting rod

Flywheel and flywheel housing

Special tools

Removing the flywheel

Renewing the rear crankshaft seal

Removing the flywheel housing

Fitting flywheel housing

Fitting the flywheel

Flexible coupling

Safety instructions

Functional description

Disassembly and dismantling the coupling

Assembling the coupling 7×1126; 8×1128.

Installation instructions

Friction disk, friction ring

Timing gear – 13 and 9 litre

Gear drive

Belt drive coolant pump, generator and AC compressor

Checking the drive belt

Check for leaks

Renewing the seal in the front cover

Crankshaft damper

Timing gear, exploded view

Special tools

Intermediate gear

Renewal of bearing in intermediate gear for the camshaft

Camshaft gear

Crankshaft gear

Camshaft

Replacement of camshaft bearing

Crankshaft

Removal

Fitting

Adjust – Machining the crankshaft

Lubrication system

General

Oil pump

Lubrication oilways

Oil pressure

Oil cooler, engine

Oil cooler view See 010009

Renewing seals and leakage testing

Oil filter

Centrifugal oil cleaner

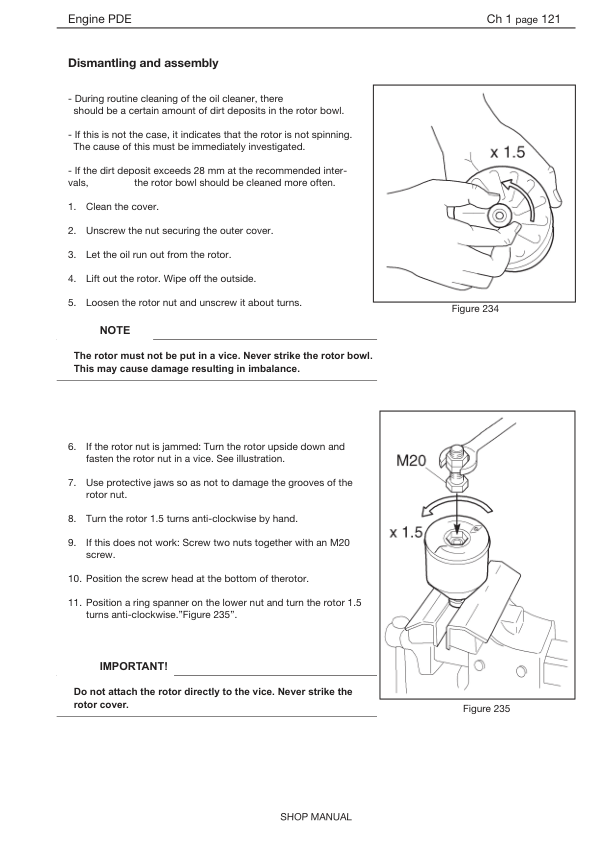

Dismantling and assembly

Operational testing of the centrifugal oil cleaner

Oil mist separator

General

High levels of oil carryover

Crankcase pressure measurement

Oil mist separator exploded view

Oil mist separator disassemble

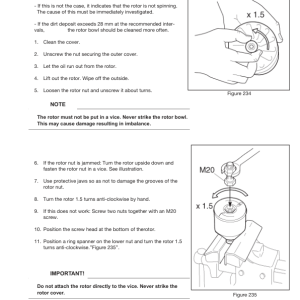

Check – Rotational speed on oil mist separator

Alternator 100 A

Check

Output test

Renewal – Bearing and carbon brushes

Oil pump, brake cooling

Exploded view

Disassemble and overhaul the oil pump

Checking and renewing parts

Oil circulate pump assemble.

Renewing the gasket

Cooling fan

View of the radiator system

Cooling system

Principal view of the cooling system

Circulation

Coolant

Checking coolant level

External leakage

Internal leakage

Checking the antifreeze level

Changing coolant

Filling coolant

Cleaning the cooling system

Disassemble the cooling unit

Disassemble the cooling unit

Thermostat and thermostat housing

Thermostat

Coolant pump

External cleaning

Internal cleaning

Technical data DC13 with PDE

General data

Technical data DC9 with PDE

General data

Troubleshooting SDP3 / Canbus

To do:

Troubleshooting – basic info

Diagnostic procedure

Use of diagnostic kit

Connection point Canpc + OBDII connector

Can bus overview

SDP3 Scania diagnostic

Troubleshooting Manual

White smoke

White smoke, water vapour

Black smoke on starting

Blue smoke

Fuel in the oil

Oil in coolant

Coolant/water in oil

Low oil pressure

High oil pressure (engine warmed up)

Abnormal wear (liner, piston rings, etc.)

Vibration, no driven components engaged

Vibration when the clutch or reverse gear is engaged

Vibration when alternator is in operation

Engine speed hunting – single-speed engines with RQ governor

Engine speed hunting – single-speed engines with RSV governor

Delivery pipe fractures

External corrosion on cylinder liner

Engine difficult to start

Fluid stroke

Knocking/noise

High oil consumption

High fuel consumption

Low compression

Low engine output

Hot engine

Cold engine

Coolant loss

Polluted coolant

High oil temperature

High exhaust temperature

Low charge air pressure

Low fuel pressure

Low system voltage

High system voltage

External oil leakage

External fuel leakage

External coolant leakage

Oil pressed out via crankcase ventilation

Turbocharger breakdown

Compressed air system

HA30 – HA45 Final S2 – 1 Engine XPI (VERKST-BOK – 1132587 – 1 – A)

Engine identification

Removal of engine assembly

Lifting the engine

Starting the engine

XPI Fuel system DA30/45

Route of the fuel on 9 and 13 litre engines

Fuel filter and water separation filter

Changing the fuel filter

Water separating prefilter

Changing the water separating fuel filter

Bleeding the fuel system using a hand pump

Overflow valve

Fuel system components

Schematic diagram of the fuel system

Important information about the fuel

Exhaust system XPI T4F

Introduction system overview

Overview – Control system for exhaust gas aftertreatment

Control unit EEC3

System overview for mechanics

System overview for electronics

Ad blue filter change

Reductant dozer

Start-up instruction for new SCR Pump

Reductant pump, function

EGR valve and actuator removal

Checking the control cylinder

Leak testing the EGR cooler

Renewing the control unit

Common rail injectors Tier4/XPI

Cylinder head – XPI system Tier4

Cylinder head, parts view. XPI system Tier4

Injector Scania XPI

Valve adjustment DC9 / DC13 with XPI

Adjustment tables DC9 / DC13

Turbocharger

Measuring radial clearance and axial clearance

VGT (Variable geometry turbo)

VGT Removal

VGT fitting

General

Changing oil filter

Oil analysis

Checking oil level

Changing the oil

Special tools

Pistons and cylinder liners

Special tools

Connecting rods

Removing and dismantling connecting rods and pistons

Renewal of bearing bushing in connecting rod

Pistons

Assembling piston and connecting rod

Cylinder block

Cylinder liner

Removing the cylinder liners

Measuring the cylinder liner height

Measuring the cylinder wear ridge and cylinder bore

Fitting the cylinder liners

Fitting the piston and connecting rod

Flywheel and flywheel housing

Special tools

Removing the flywheel

Renewing the rear crankshaft seal

Removing the flywheel housing

Fitting flywheel housing

Fitting the flywheel

Flexible coupling

Safety instructions

Functional description

Disassembly and dismantling the coupling

Assembling the coupling 7×1126; 8×1128.

Installation instructions

Friction disk, friction ring

Timing gear – 13 and 9 litre with XPI

Gear drive

Belt drive coolant pump, generator and AC compressor

Checking the drive belt

Check for leaks

Renewing the seal in the front cover

Crankshaft damper

Timing gear, exploded view

Special tools

Intermediate gear

Camshaft gear

Crankshaft gear

Camshaft

Replacement of camshaft bearing

Crankshaft

Removal

Fitting

Adjust – Machining the crankshaft

Lubrication system

General

Oil pump

Lubrication oil-ways

Oil pressure

Oil cooler, engine

Oil cooler view

Renewing seals and leakage testing

Oil filter

Centrifugal oil cleaner

Dismantling and assembly

Operational testing of the centrifugal oil cleaner

Oil mist separator

General

High levels of oil carryover

Crankcase pressure measurement

Oil mist separator exploded view

Oil mist separator disassemble

Check – rotational speed on oil mist separator

Alternator 100 A

Check

Output test

Renewal – bearing and carbon brushes

Oil pump, brake cooling circulate

Exploded view

Disassemble and overhaul the oil pump

Checking and renewing parts

Oil circulate pump assemble.

Renewing the gasket

Cooling fan

View of the radiator system

Cooling system

Principal view of the cooling system

Circulation

Coolant

Checking coolant Level

External leakage

This manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity.

This service manual mainly contains the necessary technical information for operations performed in a service workshop.

Be the first to review “Hyundai HA30, HA30A, HA45, HA45A Articulated Dump Truck Service Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.