Hyster H2.0UT, H2.5UT, H3.0UT, H3.5UT Forklift A3C1 Series Repair Manual

$25.00

Repair Manual for Hyster A3C1 Series, Models: H2.0UT, H2.5UT, H3.0UT, H3.5UT

Format: PDF

English

- Hyster H2.0UT, H2.5UT, H3.0UT, H3.5UT Forklift A3C1 Series Repair Manual: 114 Pages

- Description

- Reviews (0)

Description

Hyster H2.0UT, H2.5UT, H3.0UT, H3.5UT Forklift A3C1 Series Repair Manual

Repair Manual for Hyster A3C1 Series, Models: H2.0UT, H2.5UT, H3.0UT, H3.5UT

Format: PDF

English

- Hyster H2.0UT, H2.5UT, H3.0UT, H3.5UT Forklift A3C1 Series Repair Manual: 114 Pages

Hyster A3C1 Series, Models: H2.0UT, H2.5UT, H3.0UT, H3.5UT Manual Table Of Content:

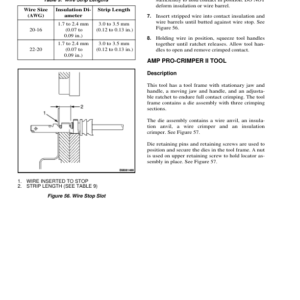

Forklift Truck Main Parts …………………………………………………………………………………………………………………….. 1

Description Of Forklift Truck Main Parts ……………………………………………………………………………………………. 1

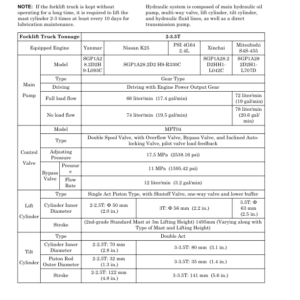

Forklift Main Technical Parameters ……………………………………………………………………………………………………….2

Main Technical Parameters ………………………………………………………………………………………………………………..2

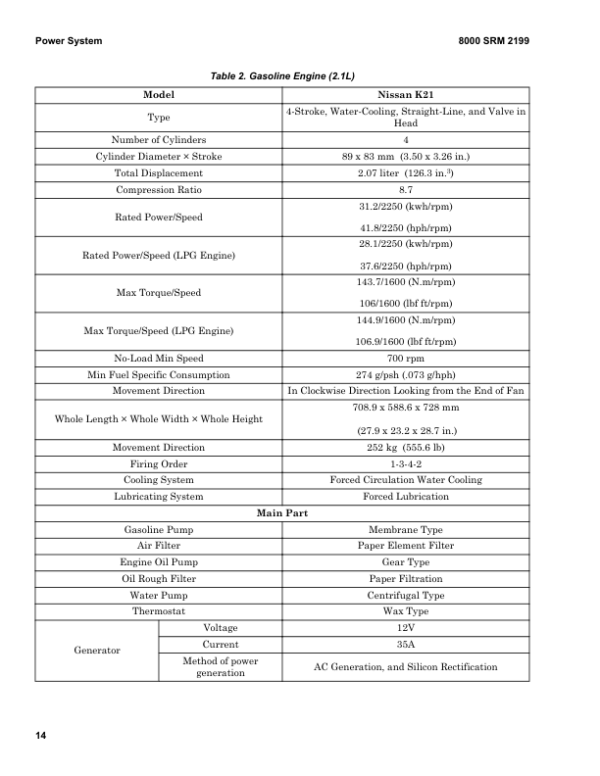

Power System …………………………………………………………………………………………………………………………………….. 12

Engine System …………………………………………………………………………………………………………………………………12

Engine Overview …………………………………………………………………………………………………………………………. 12

Inspection …………………………………………………………………………………………………………………………………….18

Engine Adjustment ……………………………………………………………………………………………………………………….20

Fuel System ………………………………………………………………………………………………………………………………… 21

Fuel Tank …………………………………………………………………………………………………………………………………21

Fuel Quantity Sensor ……………………………………………………………………………………………………………….. 23

Maintenance Of Fuel System ………………………………………………………………………………………………………24

Fuel Filter ……………………………………………………………………………………………………………………………. 24

Fuel Filter Service For Gasoline Engine ………………………………………………………………………………………24

Fuel Filter Service For Diesel Engine ………………………………………………………………………………………….25

Fuel-Water Separator (Sediment Bowl) ………………………………………………………………………………….. 25

Clean Fuel Tank …………………………………………………………………………………………………………………… 25

Hydraulic Transmission Case And Torque Converter ……………………………………………………………………………..27

Overview ………………………………………………………………………………………………………………………………………… 27

Torque Converter ……………………………………………………………………………………………………………………………. 28

Hydraulic Clutch …………………………………………………………………………………………………………………………….. 29

Control Valve, Safety Valve, And Inching Valve ………………………………………………………………………………… 30

Transmission Case ………………………………………………………………………………………………………………………….. 31

Hydraulic Oil Pump ………………………………………………………………………………………………………………………… 31

Hydraulic Oil Circuit (Hydraulic Transmission) …………………………………………………………………………………32

Speed Reducer And Speed Differential ……………………………………………………………………………………………….33

Speed Reducer …………………………………………………………………………………………………………………………….. 33

Speed Differential …………………………………………………………………………………………………………………………33

Oil Inlet/Outlet Connection Location ………………………………………………………………………………………………… 34

Towing The Lift Truck ……………………………………………………………………………………………………………………… 34

Drive Axle ………………………………………………………………………………………………………………………………………….. 34

Overview ………………………………………………………………………………………………………………………………………… 35

Maintenance Of Drive Axle ………………………………………………………………………………………………………………..35

Steering System …………………………………………………………………………………………………………………………………..36

Steering System ……………………………………………………………………………………………………………………………….36

Overview …………………………………………………………………………………………………………………………………….. 36

Hydraulic Steering Gear Assembly ……………………………………………………………………………………………. 36

Steering Cylinder ………………………………………………………………………………………………………………………38

Inspection And Reassembly Of Steering System ……………………………………………………………………………… 38

Steering Axle ………………………………………………………………………………………………………………………………….. 39

Overview …………………………………………………………………………………………………………………………………….. 39

Steering Universal Joint And King Pin …………………………………………………………………………………………..41

Troubleshoot Steering System …………………………………………………………………………………………………………..42

Brake System ………………………………………………………………………………………………………………………………………42

Overview ………………………………………………………………………………………………………………………………………… 43

Master Cylinder ……………………………………………………………………………………………………………………………….43

Wheel Brake …………………………………………………………………………………………………………………………………… 43

Automatic Clearance Regulator ……………………………………………………………………………………………………….. 47

Parking Brake ………………………………………………………………………………………………………………………………… 48

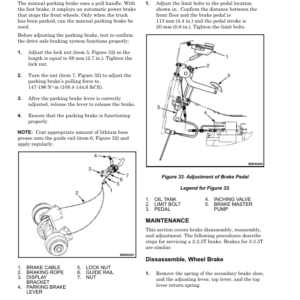

Adjustment Of Brake Pedal ……………………………………………………………………………………………………………….48

Maintenance …………………………………………………………………………………………………………………………………… 48

Dissassemble, Wheel Brake …………………………………………………………………………………………………………..48

Inspect …………………………………………………………………………………………………………………………………………50

Assemble, Wheel Brake …………………………………………………………………………………………………………………51

Test Automatic Clearance Regulator …………………………………………………………………………………………….. 53

Troubleshoot Wheel Brake …………………………………………………………………………………………………………….55

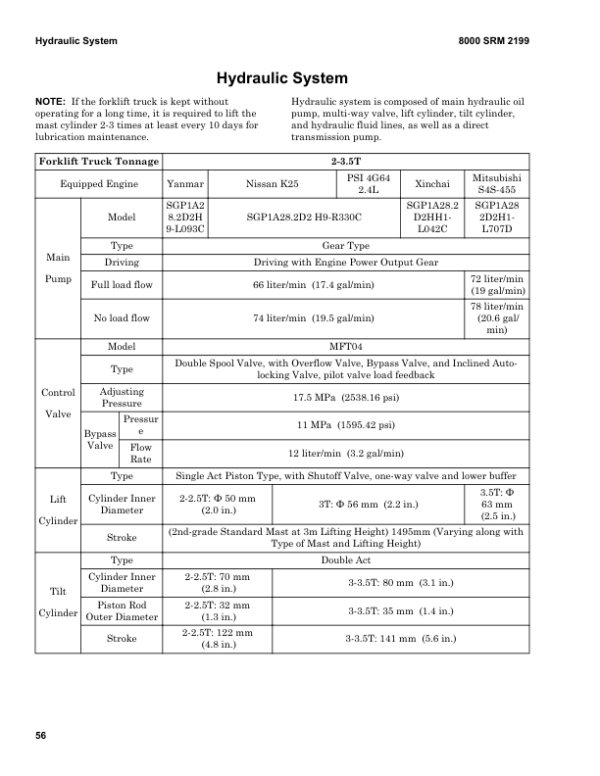

Hydraulic System ………………………………………………………………………………………………………………………………..56

Main Pump …………………………………………………………………………………………………………………………………….. 57

Control Valve And Bypass Valve ………………………………………………………………………………………………………. 57

Operation Of Spool Valve ……………………………………………………………………………………………………………….57

Neutral Position ………………………………………………………………………………………………………………………..57

Spool Valve (Pushed In): …………………………………………………………………………………………………………… 58

Spool Valve (Pulled Out): …………………………………………………………………………………………………………… 58

Main Relief Valve And Bypass (Steering Overflow) Valve ……………………………………………………………….. 58

Tilt Auto-Lock Valve ……………………………………………………………………………………………………………………. 59

Hydraulic System Main Oil Circuit ……………………………………………………………………………………………………60

Lift Cylinder …………………………………………………………………………………………………………………………………… 63

Limiting Valve …………………………………………………………………………………………………………………………………64

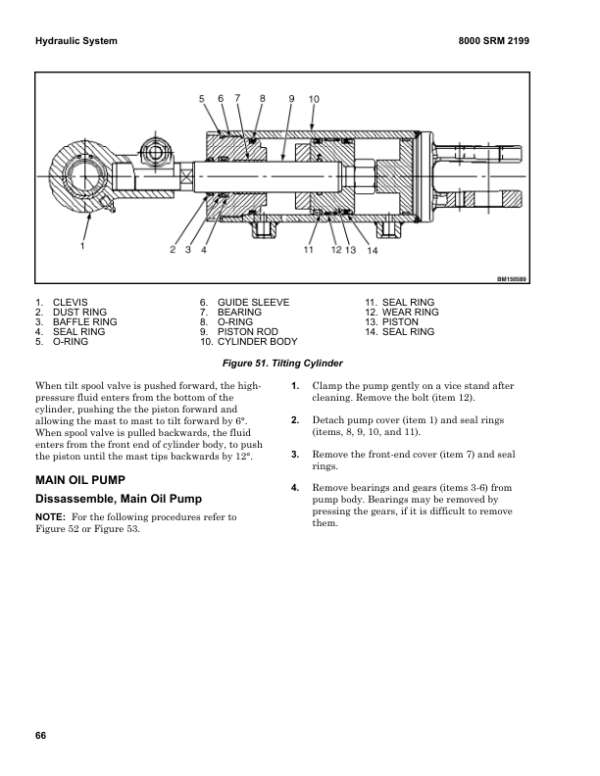

Tilt Cylinder …………………………………………………………………………………………………………………………………… 65

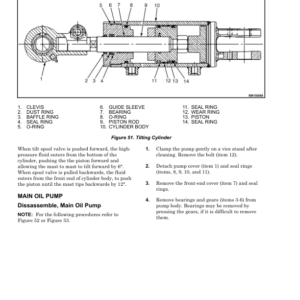

Main Oil Pump ……………………………………………………………………………………………………………………………….. 66

Dissassemble, Main Oil Pump ……………………………………………………………………………………………………….66

Inspection And Repair ………………………………………………………………………………………………………………….. 66

Assemble, Main Oil Pump ……………………………………………………………………………………………………………..71

Test ……………………………………………………………………………………………………………………………………………..72

Oil Filling Instructions ……………………………………………………………………………………………………………………..74

General Inspection Requirements …………………………………………………………………………………………………. 74

Inspection …………………………………………………………………………………………………………………………………….74

Fill Level Requirements ………………………………………………………………………………………………………………..74

Troubleshoot Hydraulic System ……………………………………………………………………………………………………….. 75

Lifting System ……………………………………………………………………………………………………………………………………. 75

Safety Procedures When Working Near Mast ……………………………………………………………………………………. 75

Inside And Outside Masts …………………………………………………………………………………………………………….. 78

Bracket ………………………………………………………………………………………………………………………………………..78

Adjust …………………………………………………………………………………………………………………………………………. 78

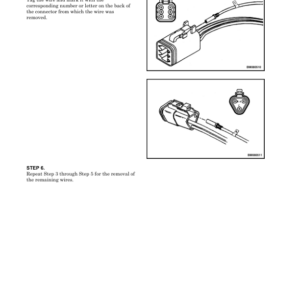

Electrical System …………………………………………………………………………………………………………………………………79

Overview ………………………………………………………………………………………………………………………………………… 80

Electrical Box …………………………………………………………………………………………………………………………………..80

Battery …………………………………………………………………………………………………………………………………………… 80

Electrical Schematics ………………………………………………………………………………………………………………………. 81

Troubleshoot Electrical System …………………………………………………………………………………………………………95

Troubleshoot Truck Safety System (Ops/Park Brake Alarm System) ……………………………………………….95

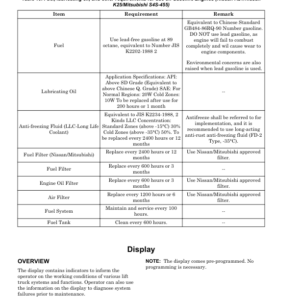

Drive, Operation, And Routine Maintenance Of Forklift Truck ………………………………………………………………..96

Transporting The Forklift Truck ………………………………………………………………………………………………………..96

Towing …………………………………………………………………………………………………………………………………………….96

Long-Term Storage Of Forklift Truck ………………………………………………………………………………………………….97

Maintenance Procedures Prior To Operation ……………………………………………………………………………………… 97

Cooling System ……………………………………………………………………………………………………………………………….. 97

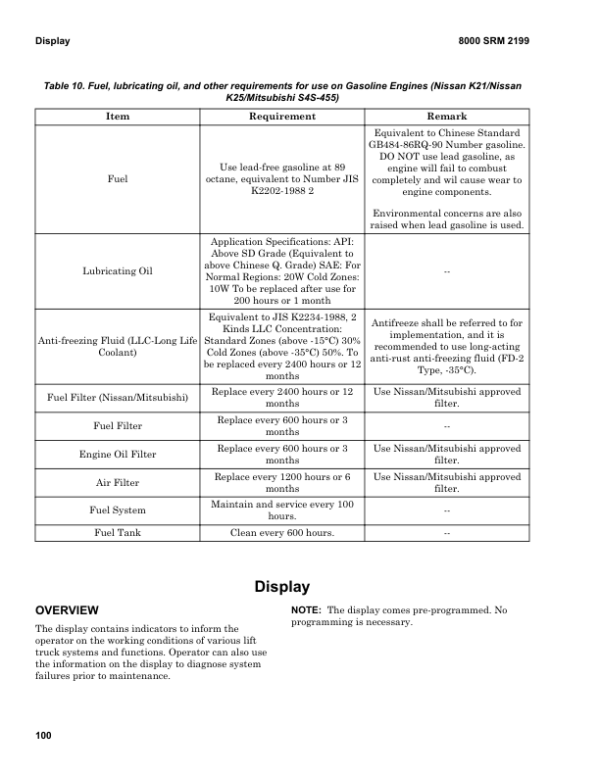

Display …………………………………………………………………………………………………………………………………………….. 100

Overview ………………………………………………………………………………………………………………………………………. 100

Remove ………………………………………………………………………………………………………………………………………….101

Install ……………………………………………………………………………………………………………………………………………103

The Service Repair Manual are updated on a regular basis, but may not reflect recent design changes to the product. Updated technical service information may be available from our website.

The Service Repair Manual provide general guidelines for maintenance and service of the A3C1 Series, Models: H2.0UT, H2.5UT, H3.0UT, H3.5UT and are intended for use by trained and experienced technicians. Failure to properly maintain equipment or to follow instructions contained in the Service Manual could result in damage to the products, personal injury, property damage or death.

• When lifting parts or assemblies, make sure all slings, chains, or cables are correctly fastened, and that the load being lifted is balanced. Make sure the crane, cables, and chains have the capacity to support the weight of the load.

• Do not lift heavy parts by hand, use a lifting mechanism.

• Wear safety glasses.

• DISCONNECT THE BATTERY CONNECTOR before doing any maintenance or repair on electric lift trucks. Disconnect the battery ground cable on internal combustion lift trucks.

• Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT THE LIFT TRUCK ON BLOCKS in the Operating Manual or the Periodic Maintenance section.

Caution:

• Always fasten a DO NOT OPERATE tag to the controls of the unit when making repairs, or if the unit needs repairs.

• Be sure to follow the WARNING and CAUTION notes in the instructions.

• Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel are flammable.

• Be sure to follow the necessary safety precautions when handling these fuels and when working on these fuel systems.

• Batteries generate flammable gas when they are being charged. Keep fire and sparks away from the area. Make sure the area is well ventilated.

Be the first to review “Hyster H2.0UT, H2.5UT, H3.0UT, H3.5UT Forklift A3C1 Series Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.