Gehl Z17, Mustang 170Z Compact Excavator Repair Service Manual

$38.00

Language: English

Format: PDF

Applicable for the Gehl Excavator Model Gehl Z17, Mustang 170Z

- Gehl Gehl Z17, Mustang 170Z Excavator Repair Service Manual – 400 Pages

- Gehl Gehl Z17, Mustang 170Z Excavator Operators Manual – 210 Pages

- Gehl Gehl Z17, Mustang 170Z Excavator Parts Manual – 214 Pages

- Description

- Reviews (0)

Description

Gehl Z17, Mustang 170Z Compact Excavator Repair Service Manual

Language: English

Format: PDF

Applicable for the Gehl Excavator Model Gehl Z17, Mustang 170Z

- Gehl Gehl Z17, Mustang 170Z Excavator Repair Service Manual – 400 Pages

- Gehl Gehl Z17, Mustang 170Z Excavator Operators Manual – 210 Pages

- Gehl Gehl Z17, Mustang 170Z Excavator Parts Manual – 214 Pages

Table of Content of the Gehl Z17, Mustang 170Z Excavator Manual:

CHAPTER 1 – GENERAL CAUTIONS FOR MAINTENANCE WORK

1-1 Correct Work …………………………………………………………………………………………………………………………………………………….. 1-1

1-2 Safety Precautions …………………………………………………………………………………………………………………………………………….. 1-1

1-3 Preparations……………………………………………………………………………………………………………………………………………………… 1-1

1-4 Cautions for Disassembly and Reassembly…………………………………………………………………………………………………………… 1-1

1-5 Cautions for Removal and Installation of Hydraulic Equipment ………………………………………………………………………………… 1-2

1-6 Cautions for Removal and Installation of Hydraulic Piping……………………………………………………………………………………….. 1-2

1-7 Cautions for Handling Seals………………………………………………………………………………………………………………………………… 1-3

1-8 Correct Installation of Hydraulic Hose …………………………………………………………………………………………………………………… 1-3

1-9 Specifications of Hydraulic Hose………………………………………………………………………………………………………………………….. 1-6

1-10 Air Release of Hydraulic Equipment………………………………………………………………………………………………………………….. 1-11

CHAPTER 2 – TECHNICAL DATA

2-1 Specifications …………………………………………………………………………………………………………………………………………………. 2-1-1

2-2 Outline Drawing and Working Area……………………………………………………………………………………………………………………. 2-2-1

2-3 Weight List of Main Parts …………………………………………………………………………………………………………………………………. 2-3-1

2-4 Lifting Capacity List …………………………………………………………………………………………………………………………………………. 2-4-1

CHAPTER 3 – SERVICE STANDARDS

3-1 Machine Performance ……………………………………………………………………………………………………………………………………… 3-1-1

3-2 Engine …………………………………………………………………………………………………………………………………………………………… 3-2-1

3-3 Undercarriage…………………………………………………………………………………………………………………………………………………. 3-3-1

3-3-1 Rubber Crawler Specifications ………………………………………………………………………………………………………………….. 3-3-1

3-4 Controls …………………………………………………………………………………………………………………………………………………………. 3-4-1

3-5 Hydraulic Equipment ……………………………………………………………………………………………………………………………………….. 3-5-1

3-5-1 Hydraulic Cylinders …………………………………………………………………………………………………………………………………. 3-5-1

3-6 Implement………………………………………………………………………………………………………………………………………………………. 3-6-1

3-6-1 Front Attachments …………………………………………………………………………………………………………………………………… 3-6-1

3-6-2 Blade Moving Device……………………………………………………………………………………………………………………………….. 3-6-2

3-6-3 Bucket Teeth ………………………………………………………………………………………………………………………………………….. 3-6-2

3-7 List of Tightening Torque………………………………………………………………………………………………………………………………….. 3-7-1

3-7-1 Machine…………………………………………………………………………………………………………………………………………………. 3-7-1

3-7-2 Engine …………………………………………………………………………………………………………………………………………………… 3-7-4

3-7-3 Tightening Torque for General Bolts and Nuts…………………………………………………………………………………………….. 3-7-4

3-7-4 Hydraulic Hose Joint ……………………………………………………………………………………………………………………………….. 3-7-5

CHAPTER 4 – ENGINE

4-1 Exploded View………………………………………………………………………………………………………………………………………………… 4-1-1

4-2 Measurement, Inspection and Adjustment………………………………………………………………………………………………………….. 4-2-1

4-2-1 Measuring the Compression Pressure ……………………………………………………………………………………………………….. 4-2-1

4-2-2 Adjusting the Valve Clearance ………………………………………………………………………………………………………………….. 4-2-2

4-2-3 Checking the V-belt Tension …………………………………………………………………………………………………………………….. 4-2-3

4-2-4 Checking the Fuel Injection Valve ……………………………………………………………………………………………………………… 4-2-3

4-2-5 Checking and adjusting the Fuel Injection Timing………………………………………………………………………………………… 4-2-5

4-2-6 Adjusting the Maximum (or Minimum) Idling Speed……………………………………………………………………………………… 4-2-7

4-2-7 Checking the Cooling Water System and Radiator for Water Leakage …………………………………………………………… 4-2-7

4-2-8 Checking the Sensors ……………………………………………………………………………………………………………………………… 4-2-8

4-3 Measurement Procedure, Service Data and Corrective Action………………………………………………………………………………. 4-3-1

4-3-1 Cylinder Head…………………………………………………………………………………………………………………………………………. 4-3-1

4-3-2 Cylinder Block ………………………………………………………………………………………………………………………………………… 4-3-6

4-3-3 Valve Rocker Arm …………………………………………………………………………………………………………………………………… 4-3-8

4-3-4 Piston and Piston Rings …………………………………………………………………………………………………………………………. 4-3-10

4-3-5 Connecting Rod…………………………………………………………………………………………………………………………………….. 4-3-13

4-3-6 Cam shaft …………………………………………………………………………………………………………………………………………….. 4-3-16

4-3-7 Crank shaft …………………………………………………………………………………………………………………………………………… 4-3-17

4-3-8 Gears…………………………………………………………………………………………………………………………………………………… 4-3-20

4-3-9 Trochoid Pump ……………………………………………………………………………………………………………………………………… 4-3-21

4-4 Precautions for Reassembly …………………………………………………………………………………………………………………………….. 4-4-1

4-5 Electrical Equipment………………………………………………………………………………………………………………………………………… 4-5-1

4-5-1 Starter Motor ………………………………………………………………………………………………………………………………………….. 4-5-1

4-5-2 Alternator……………………………………………………………………………………………………………………………………………….. 4-5-2

CHAPTER 5 – HYDRAULIC SYSTEM

5-1 Outline …………………………………………………………………………………………………………………………………………………………… 5-1-1

5-1-1 Control Valve Operation …………………………………………………………………………………………………………………………… 5-1-4

5-1-2 Additional Operation of Control Valve ………………………………………………………………………………………………………… 5-1-6

5-2 Hydraulic Circuit Schematic ……………………………………………………………………………………………………………………………… 5-2-1

5-2-1 For Standard Type Machines ……………………………………………………………………………………………………………………. 5-2-1

5-3 Circuit Operation …………………………………………………………………………………………………………………………………………….. 5-3-1

5-3-1 Boom …………………………………………………………………………………………………………………………………………………….. 5-3-1

5-3-2 Arm……………………………………………………………………………………………………………………………………………………….. 5-3-3

5-3-3 Bucket …………………………………………………………………………………………………………………………………………………… 5-3-5

5-3-4 Swing…………………………………………………………………………………………………………………………………………………….. 5-3-7

5-3-5 Boom Swing …………………………………………………………………………………………………………………………………………… 5-3-9

5-3-6 Blade …………………………………………………………………………………………………………………………………………………… 5-3-11

5-3-7 Travel ………………………………………………………………………………………………………………………………………………….. 5-3-13

5-3-8 Track Gauge Change ……………………………………………………………………………………………………………………………. 5-3-15

5-3-9 Travel Straight (Simultaneous Operation of Boom, Arm, Bucket, and Boom Swing)……………………………………….. 5-3-17

5-3-10 Simultaneous Operation of Boom and Bucket …………………………………………………………………………………………. 5-3-19

5-3-11 Hydraulic P.T.O. ………………………………………………………………………………………………………………………………….. 5-3-21

5-4 Pressure Adjustment……………………………………………………………………………………………………………………………………….. 5-4-1

5-4-1 Relief Valves ………………………………………………………………………………………………………………………………………….. 5-4-1

5-4-2 Swing Brake Valve ………………………………………………………………………………………………………………………………….. 5-4-3

5-4-3 Cut-Off Valve………………………………………………………………………………………………………………………………………….. 5-4-4

CHAPTER 6 – HYDRAULIC EQUIPMENT

6-1 Hydraulic Pump………………………………………………………………………………………………………………………………………………. 6-1-1

6-2 Control Valve…………………………………………………………………………………………………………………………………………………. 6-2-1

6-3 Pilot Valve ……………………………………………………………………………………………………………………………………………………… 6-3-1

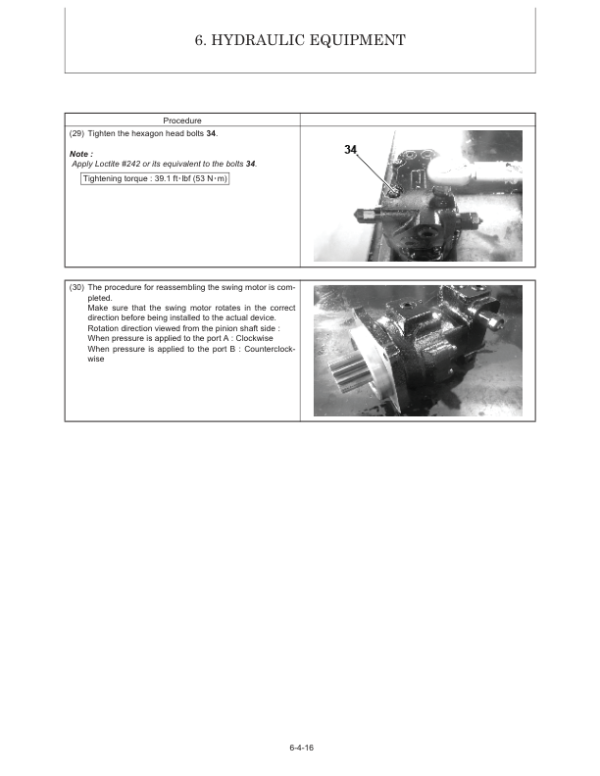

6-4 Swing Motor …………………………………………………………………………………………………………………………………………………… 6-4-1

6-5 Travel Motor …………………………………………………………………………………………………………………………………………………… 6-5-1

CHAPTER 7 – ADJUSTMENT AND REPAIR

7-1 Electric Equipment of Machine………………………………………………………………………………………………………………………….. 7-1-1

7-1-1 Parts Layout of Electrical Equipment …………………………………………………………………………………………………………. 7-1-1

7-1-2 Monitor and Alarm Systems ……………………………………………………………………………………………………………………… 7-1-2

7-1-3 Wiring Diagram……………………………………………………………………………………………………………………………………….. 7-1-5

7-1-4 Circuit Description of Engine Start and Stop, and Battery Charging ……………………………………………………………….. 7-1-7

7-1-5 Removal and Reinstallation of Engine ……………………………………………………………………………………………………….. 7-1-9

7-1-6 Removal and Reinstallation of Starter Motor……………………………………………………………………………………………… 7-1-15

7-1-7 Removal and Reinstallation of Fuel Injection Pump……………………………………………………………………………………. 7-1-16

7-1-8 Removal and Reinstallation of Fuel Tank………………………………………………………………………………………………….. 7-1-18

7-1-9 Removal and Reinstallation of Radiator ……………………………………………………………………………………………………. 7-1-21

7-2 Undercarriage…………………………………………………………………………………………………………………………………………………. 7-2-1

7-2-1 Outline …………………………………………………………………………………………………………………………………………………… 7-2-1

7-2-2 Points of Reassembly………………………………………………………………………………………………………………………………. 7-2-2

7-2-3 Crawler Tension Adjustment Procedure……………………………………………………………………………………………………… 7-2-3

7-2-4 Removal and Reinstallation of Crawler ………………………………………………………………………………………………………. 7-2-4

7-2-5 Disassembly and Reassembly of Idler ……………………………………………………………………………………………………….. 7-2-5

7-2-6 Disassembly and Reassembly of Track Roller…………………………………………………………………………………………….. 7-2-7

7-2-7 Removal and Reinstallation of Track Gauge Change Cylinder ………………………………………………………………………. 7-2-9

7-3 Controls …………………………………………………………………………………………………………………………………………………………. 7-3-1

7-3-1 Control Train…………………………………………………………………………………………………………………………………………… 7-3-1

7-3-2 Mechanical Control Linkage ……………………………………………………………………………………………………………………… 7-3-2

7-3-3 Adjustment of Control Levers ……………………………………………………………………………………………………………………. 7-3-4

7-3-4 Adjustment of Travel Levers……………………………………………………………………………………………………………………… 7-3-5

7-3-5 Adjustment of Boom Swing Pedal ……………………………………………………………………………………………………………… 7-3-6

7-3-6 Adjustment of Blade Lever ……………………………………………………………………………………………………………………….. 7-3-6

7-3-7 Adjustment of Lock Lever Switch ………………………………………………………………………………………………………………. 7-3-7

7-3-8 Adjustment of Accelerator Lever ……………………………………………………………………………………………………………….. 7-3-8

7-3-9 Adjustment of P.T.O. Pedal………………………………………………………………………………………………………………………. 7-3-9

7-3-10 Adjustment Procedure of Travel Alarm Switch (Left and Right) ………………………………………………………………….. 7-3-10

7-4 Swing Bearing ………………………………………………………………………………………………………………………………………………… 7-4-1

7-5 Hydraulic Equipment ……………………………………………………………………………………………………………………………………….. 7-5-1

7-5-1 Removal and Reinstallation of Hydraulic Pump …………………………………………………………………………………………… 7-5-1

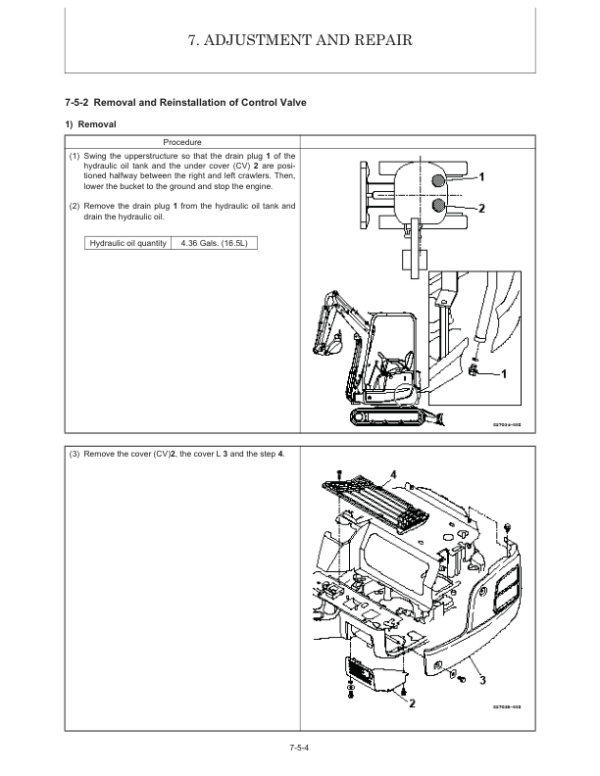

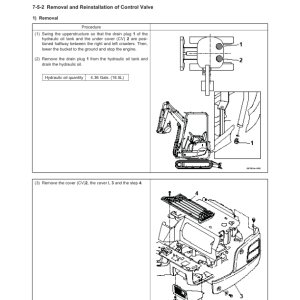

7-5-2 Removal and Reinstallation of Control Valve ………………………………………………………………………………………………. 7-5-4

7-5-3 Removal and Reinstallation of Swing Motor………………………………………………………………………………………………… 7-5-7

7-5-4 Removal and Reinstallation of Swivel Joint……………………………………………………………………………………………….. 7-5-10

7-5-5 Disassembly and Reassembly of Swivel Joint …………………………………………………………………………………………… 7-5-13

7-5-6 Disassembly and Reassembly of Hydraulic Cylinders ………………………………………………………………………………… 7-5-16

7-5-7 Hydraulic Oil Tank …………………………………………………………………………………………………………………………………. 7-5-20

7-5-8 Piping Layout………………………………………………………………………………………………………………………………………… 7-5-26

7-6 Implement………………………………………………………………………………………………………………………………………………………. 7-6-1

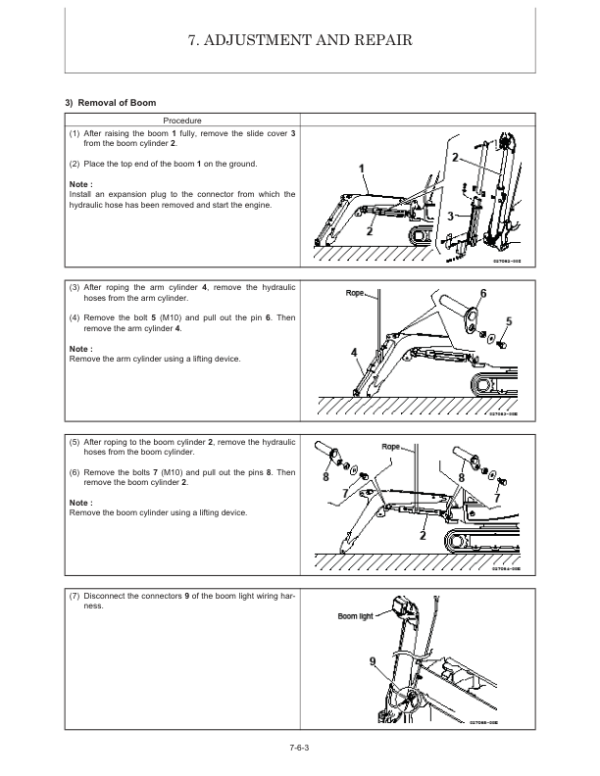

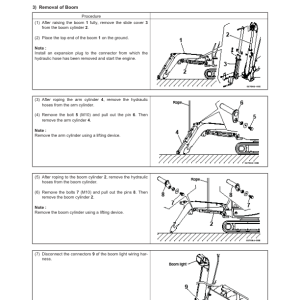

7-6-1 Removal and Reinstallation of Implement…………………………………………………………………………………………………… 7-6-1

CHAPTER 8 – PERIODIC INSPECTION AND SERVICING

8-1 List of Periodic Inspection and Servicing……………………………………………………………………………………………………………….. 8-1

CHAPTER 9 – FUEL, LUBE OIL AND GREASE RECOMMENDED

9. Fuel, Lube Oil and Grease Recommended……………………………………………………………………………………………………………… 9-1

CHAPTER 10 – TROUBLESHOOTING

10-1 Non-Breakdowns…………………………………………………………………………………………………………………………………………. 10-1-1

10-1-1 Natural Release of Bucket…………………………………………………………………………………………………………………….. 10-1-1

10-1-2 Discontinuous Arm Movement ………………………………………………………………………………………………………………. 10-1-1

10-1-3 Drifting of Upperstructure on Quick Travel Operation ……………………………………………………………………………….. 10-1-2

10-1-4 Thermal Shock of Travel Motor ……………………………………………………………………………………………………………… 10-1-3

10-1-5 Time Lag on Travel Speed Switching……………………………………………………………………………………………………… 10-1-4

10-1-6 Fluctuation in Oil Level of Hydraulic Oil Tank Due to Temperature Change…………………………………………………. 10-1-5

10-2 Troubleshooting…………………………………………………………………………………………………………………………………………… 10-2-1

10-2-1 Machine and Engine…………………………………………………………………………………………………………………………….. 10-2-1

10-2-2 Electrical Equipment on Panel …………………………………………………………………………………………………………….. 10-2-22

CHAPTER 11 – REFERENCE DATA

11-1 Specifications for Attachment………………………………………………………………………………………………………………………… 11-1-1

This Service Manual is intended for Gehl Z17, Mustang 170Z Excavator so as to give the owner/operator assistance in preparing, adjusting, maintaining and servicing the machine. More importantly, this manual provides an operating plan for safe and proper use of the machine. Major points of safe operation are

detailed in Chapter 2 – Safety. Read and understand the contents of this manual completely and become familiar with the machine before

attempting to operate it..

Throughout this manual, information is introduced by the word NOTE or IMPORTANT. Be sure to read the message carefully and comply with the message. Following this information will improve operating and maintenance efficiency, help to avoid breakdown and damage and extend the service life of the machine.

Be the first to review “Gehl Z17, Mustang 170Z Compact Excavator Repair Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.