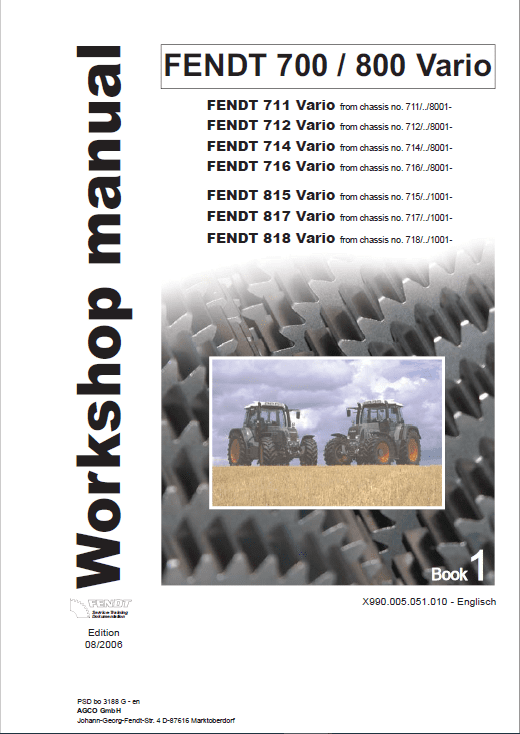

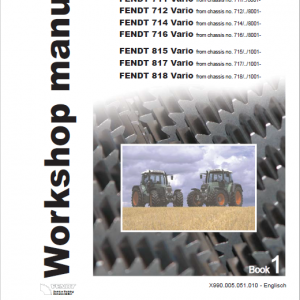

Fendt 711, 712, 714, 716 Vario COM II Tractors Workshop Repair Manual

$50.00

- Fendt 711, 712, 714, 716 Vario COM II Tractors Workshop Repair Manual – 1246 Pages

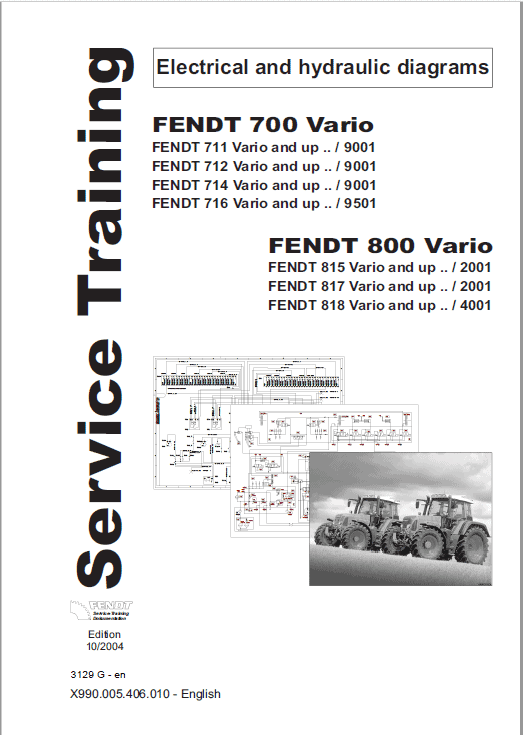

- Fendt 700 Vario COM II Wiring Diagram and Schematics – 61 Pages

- DEUTZ BF Engine Manual – 498 Pages

- Operators Manual – 267 Pages

- Technical Data – 33 Pages

Please see description below for applicable models

- Description

- Reviews (0)

Description

Fendt 711, 712, 714, 716 Vario COM II Tractors Workshop Repair Manual

Applicable Models:

| Model | Chassis Number | Serial |

| FENDT 711 Vario COM II | 711 | 8001- |

| FENDT 712 Vario COM II | 712 | 8001- |

| FENDT 714 Vario COM II | 714 | 8001- |

| FENDT 716 Vario COM II | 716 | 8001- |

- Fendt 711, 712, 714, 716 Vario COM II Tractors Workshop Repair Manual – 1246 Pages

- Fendt 700 Vario COM II Wiring Diagram and Schematics – 61 Pages

- DEUTZ BF Engine Manual – 498 Pages

- Operators Manual – 267 Pages

- Technical Data – 33 Pages

Workshop Manual TABLE OF CONTENTS

- 0000 Tractor / General system

- 1000 Transmission

Transmission control unit

Differential

Axle drive

Handbrake

Housing

Brake system

Vario transmission unit

Emergency control

Clutch actuation system

Cardan brake

ML range control

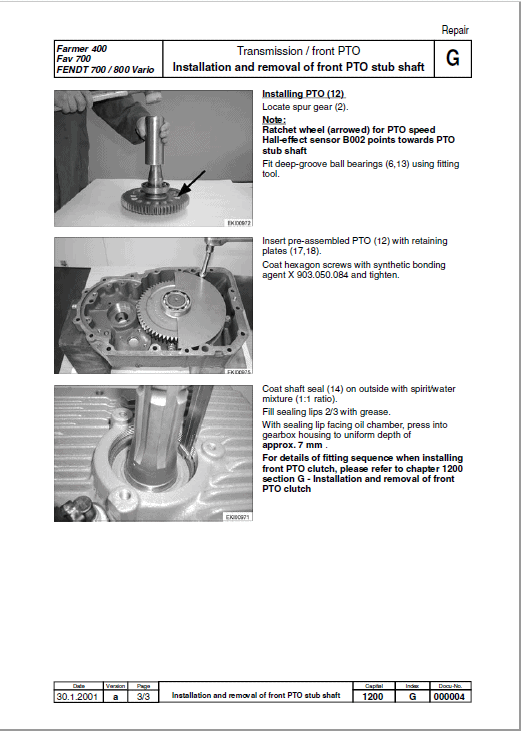

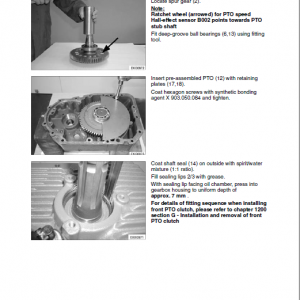

Front PTO

Live PTO

Front-wheel drive

Hydrodamp

Hydraulic pump

Transmission lubrication system

Pump drive

ML adjustment

Enhanced control system valves

Enhanced control system pipes

- 2000 Engine

Engine

Cylinder head

Fuel system

Exhaust gas system - 3000 Front axle

Front axle support

Axle housing

Suspension

Suspension valve fitting

Suspension pipe

Track rod

Steering cylinder

Frame

Cardan shaft

Diff. lock actuation system

- 4000 Steering

Steering wheel

Hydraulic steering assembly

- 5000 Vehicle Body

Design

Driver seat

Trailer hitch

Trailer hitch coupling

Cab mount, suspension - 5500 Air Conditioning System

Compressor drive

Coolant lines

Evaporator

Condenser

Electrical cables

- 8100 Cab

Heater

Ventilation

Windscreen wipers

Cable loom

- 8600 Power lift

Electrohydraulic EPC control

External control

Control lifting gear

- 8700 Three-point hitch

Lift arms

Support

- 8800 Compressed air system

Compressor

Brake fittings

Lines

Electrical actuation system

Air tank

- 8900 Front loader

Mounting frame

Hydraulic implement actuation system

3. hydraulic circuit

Multi-coupling

Pipes

Lift cylinder

- 9000 Electrical System

Alternator

Starter lockout

Fuses

Battery system

Starter motor system

- 9200 Front power lift

Lift gear

External control

Cylinder

Pipes

Enhanced control power lift

Frame - 9400 Hydraulic pump assembly

LS pump

Transmission pump

Steering pump - 9500 Hydraulic pipes

Base circle

Power lift

with oil cooler

Hydraulic trailer brake

Steering

Reversing system

- 9600 Hydraulic equipment

Hydraulic connections

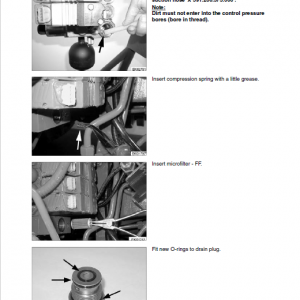

Central control block (ZSB)

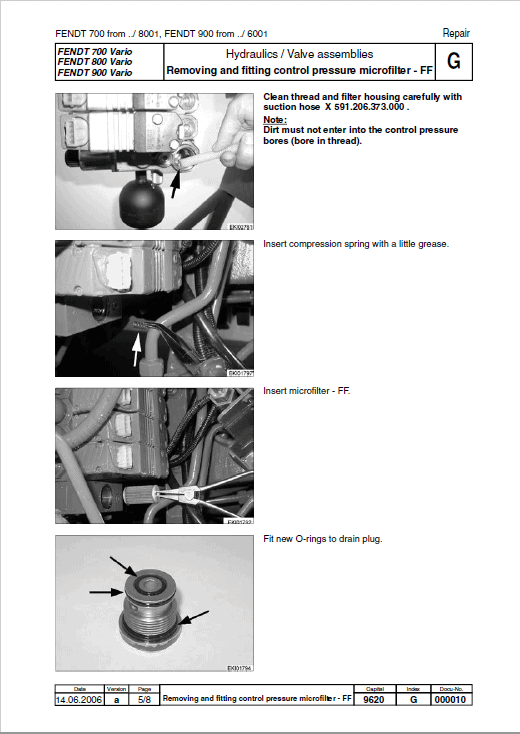

Valve assembly

External pressure supply

Valve supplement - 9700 Electronics

Instrument panel

Terminal

LBS – agricultural bus system

Transducer

Radar sensor

E-box

Transmission actuator unit

Drive switch

Control panel

Engine EDC

ECU, lift gear

- 9900 Service

Special tools

FENDIAS

Manual Extract

This workshop manual provides notes for trained technicians to maintain our tractors. Read and observe the information in this documentation. This will help you prevent accidents.

Intended use includes maintaining operating the service and maintenance conditions as specified by the manufacturer. Operation, maintenance and repair of the tractor may only be carried out by people who are familiar with this equipment and aware of the associated dangers. Ensure that this documentation is available to and understood by everyone involved in operation, maintenance and repair. Not observing this documentation

can lead to faults, damage and personal injury.

The prerequisite for the Fendt 711, 712, 714, 716 Vario COM II tractors being correctly serviced and maintained is the perfect condition and availability of all necessary equipment, standard tools and general workshop equipment as well as special tools. Special tools must only be used where absolutely necessary. The tools are displayed where they need to be used in each case.

The machine must be maintained according to its proper use. Always replace parts with genuine FENDT spare parts! When ordering parts, please provide the chassis number as per the most up-to-date spare parts documentation.

Workshops should also refer to documentation on maintenance work and technical data. Once maintenance is complete, take a test drive to ensure the vehicle’s correct operation and road safety.

Be the first to review “Fendt 711, 712, 714, 716 Vario COM II Tractors Workshop Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.