Doosan DX160LC-3 Excavator Service Manual

$35.00

Manual Included:

- Service Manual: 891 Pages

Specifications:

- Brand: Doosan Excavator

- Model: DX160LC-3

- Serial Number: 50001 and Up

- Type: Excavator

- Manuals: Service Manual

- Publication Number: 950106-01172E

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

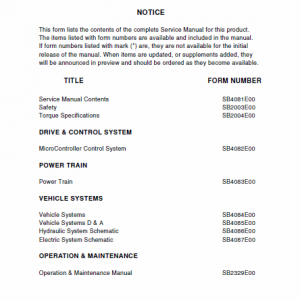

Table of Contents:-

Safety

Track Excavator Maintenance Safety……………………………………………SP002322

Specifications

Specifications for DX160LC-3………………………………………………………SP002509

General Maintenance

General Maintenance Instructions………………………………………………..SP002454

Standard Torques………………………………………………………………………SP002404

Upper Structure

Cabin……………………………………………………………………………………….SP002324

Counterweight……………………………………………………………………………SP002510

Fuel Tank………………………………………………………………………………….SP002511

Fuel Transfer Pump (Option)……………………………………………………….SP002546

Swing Bearing……………………………………………………………………………SP002329

Swing Reduction Gear………………………………………………………………..SP002526

Lower Structure and Chassis

Track Assembly…………………………………………………………………………SP002524

Engine and Drivetrain

Engine Coolant Heater (Option)…………………………………………………..SP002328

Drive Coupling (Main Pump)………………………………………………………..SP002515

Hydraulics

Hydraulic System Troubleshooting, Testing and Adjustment……………SP002538

Accumulator………………………………………………………………………………SP002455

Center Joint (Swivel)…………………………………………………………………..SP002456

Cylinders………………………………………………………………………………….. SP002539

Swing Motor………………………………………………………………………………SP002527

Travel Device…………………………………………………………………………….SP002514

Main Pump………………………………………………………………………………..SP002517

Gear Pump……………………………………………………………………………….SP002500

Main Control Valve…………………………………………………………………….SP002528

Remote Control Valve (Work Lever / Joystick)……………………………….SP002395

Travel Control Valve (with Damper)………………………………………………SP002381

Solenoid Valve Assembly……………………………………………………………SP002406

Breaker EPPR Valve (Option)……………………………………………………..SP002458

Dozer Valve………………………………………………………………………………SP002529

Hydraulic Schematic (DX160LC-3)……………………………………………….SP002518

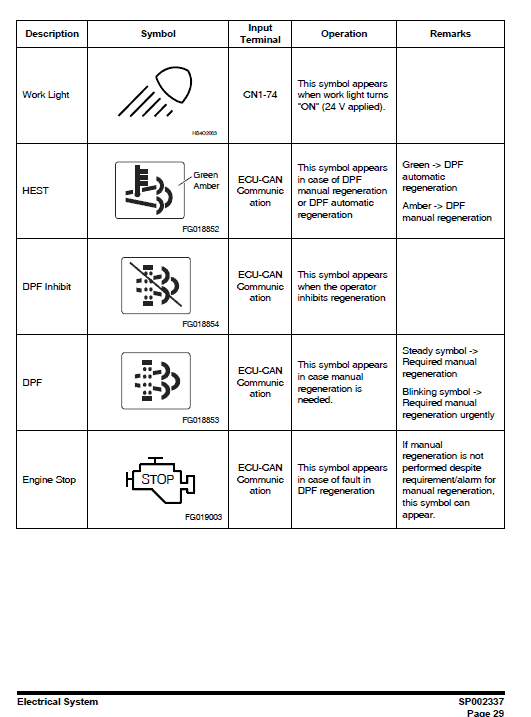

Electrical System

Electrical System……………………………………………………………………….SP002337

Electrical Schematic…………………………………………………………………..SP002508

Attachments

Boom and Arm…………………………………………………………………………..SP002513

Bucket………………………………………………………………………………………SP002506

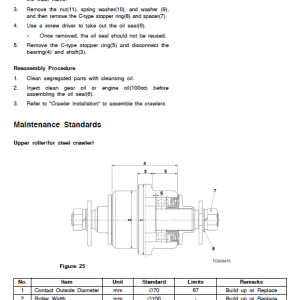

Doosan DX160LC-3 Manual Instruction Extract:

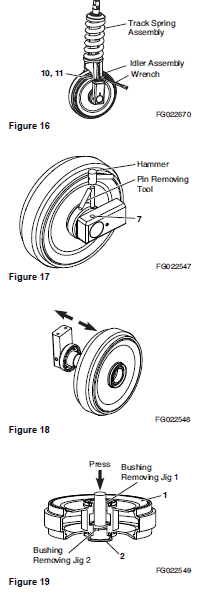

1.Detach T/Spring assembly from Idler assembly.

Remove 4-M16 bolts and washers (10 and 11, Figure 16).

2.Remove the plug (8, Figure 15) from the bearing (4, Figure 15) (using 6 mm “L” wrench).

NOTE: About 330 cc of oil will be discharged. Prepare

an oilcloth or pan to prevent spillage on the

ground.

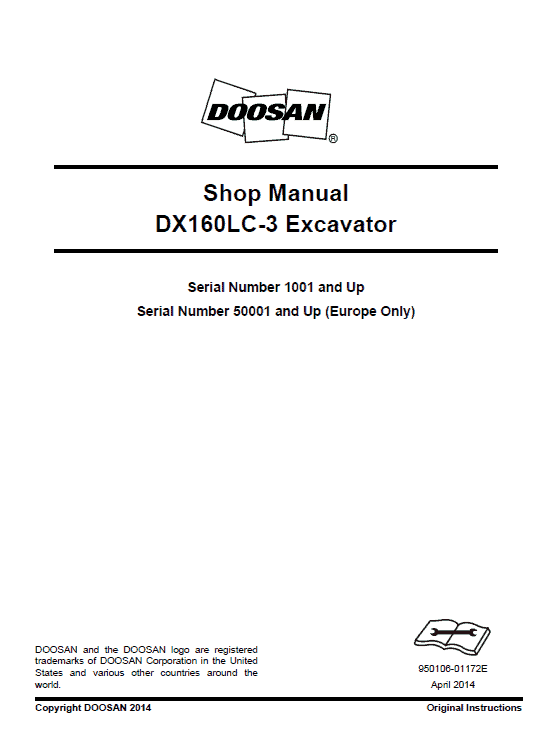

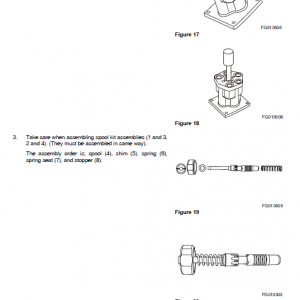

3.Using a hammer and pin-removing tool, remove the pin (7, Figure 17) on one side.

4.Remove the bearing (4, Figure 15) on the side from which the pin (7, Figure 17) has been removed.

5.From the removed bearing (4, Figure 15) and front (1, Figure 15), separate the floating seal (5, Figure 15).

6.From the shaft (3, Figure 15), separate the O-ring (6, Figure 15).

NOTE: If the O-ring is not removed, the bearing

subassembly on the opposite side will be

difficult to separate

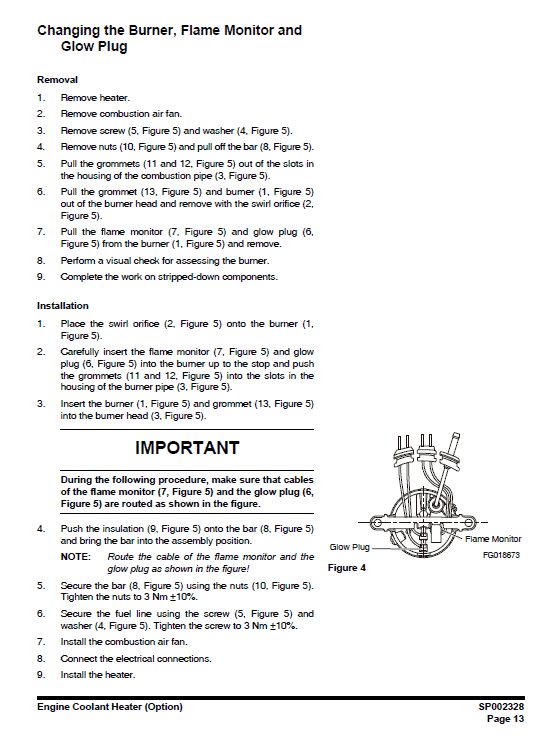

7.Separate the bearing subassembly on the opposite side of the front (1, Figure 15).

8.Separate the floating seal (5, Figure 15) from the separated bearing subassembly and front (1, Figure 15).

9.Separate the pin (7, Figure 15) from the separated bearing subassembly.

10.Separate the shaft (3, Figure 15) from the bearing (4, Figure 15).

11.Separate the O-ring (6, Figure 15) from the shaft (3, Figure 15).

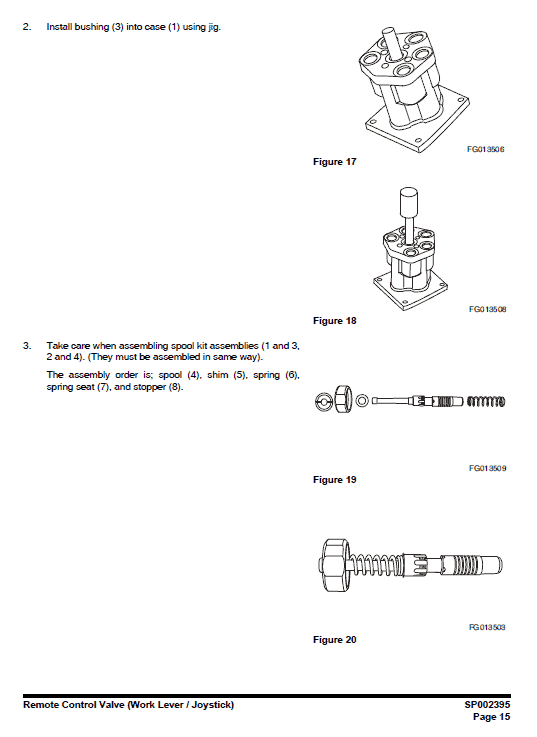

12.Separate the bushing (2, Figure 19) from the front (1, Figure 19).

NOTE: Insert jig 2, and press jig 1 to separate.

Use the hydraulic press for pressing the jig. Be

careful of sputtering.

13.Turn the front upside down. Separate the bushing (2, Figure 19) in the same manner as described above (Figure 19)

How to Use The Doosan DX160LC-3 Excavator Guide Manual:

This manual provides information for servicing the DX160LC-3 Doosan Excavator. All service procedures are broken down into detailed steps, listed in their recommended sequence. The manual uses both photographs and drawings to help locate and itemize components. The table of Contents on the preceding pages is your best tool for finding the service procedure you need. Be certain to observe all Safety information included in these pages.

A schematic of each of the major engine systems is provided at the beginning of the section of the manual devoted to troubleshooting and repairing that particular system.

Basic safety precautions are list in the Safety section of the Doosan DX160LC-3 Excavator Service Manual. Additional safety precautions are list in the Safety section of the owner/operation/maintenance publication. Specific safety warnings for all these publications are provided in the description of operations where hazards exist. WARNING labels have also been put on the product to provide instructions and to identify specific hazards.

Be the first to review “Doosan DX160LC-3 Excavator Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.