Challenger MT835C, MT845C, MT855C, MT865C, MT875C Tractor Service Manual

$40.00

Challenger MT835C, MT845C, MT855C, MT865C, MT875C Tractor Workshop Manual : 2963 Pages

Challenger MT835C, MT845C, MT855C, MT865C, MT875C Tractor Repair Schedule Manual : 840 Pages

Format: PDF

Book Number: 79033095 & AG333729B

English

Issued July, 2016

- Description

- Reviews (0)

Description

Challenger MT835C, MT845C, MT855C, MT865C, MT875C Tractor Service Manual

Manual for: AGCO Challenger MT800C Series Tractor

Format: PDF

Book Number: 79033095 & AG333729B

English

Issued July, 2016

Challenger MT835C, MT845C, MT855C, MT865C, MT875C Tractor Workshop Manual : 2963 Pages

Challenger MT835C, MT845C, MT855C, MT865C, MT875C Tractor Repair Schedule Manual : 840 Pages

MT800C Series Manual TABLE OF CONTENTS

INTRODUCTION……………………………………………………………………………………………………………………………….01

ENGINE ……………………………………………………………………………………………………………………………………………02

POWERTRAIN……………………………………………………………………………………………………………………………………03

FRAME ……………………………………………………………………………………………………………………………………………..04

STEERING AND BRAKE SYSTEM ………………………………………………………………………………………………………05

IMPLEMENT AND THREE-POINT HITCH HYDRAULIC SYSTEMS………………………………………………………06

ELECTRICAL …………………………………………………………………………………………………………………………………….07

AIR SYSTEM ……………………………………………………………………………………………………………………………………..08

VIRTUAL TERMINAL…………………………………………………………………………………………………………………………09

CAB …………………………………………………………………………………………………………………………………………………..10

Volume 2

HEATING VENTILATION AND AIR CONDITIONING…………………………………………………………………………..11

BALLASTING …………………………………………………………………………………………………………………………………….12

APPEARANCE GROUP………………………………………………………………………………………………………………………..13

ELECTRONICS……………………………………………………………………………………………………………………………………14

MT835C, MT845C, MT855C, MT865C, MT875C Manual Extract

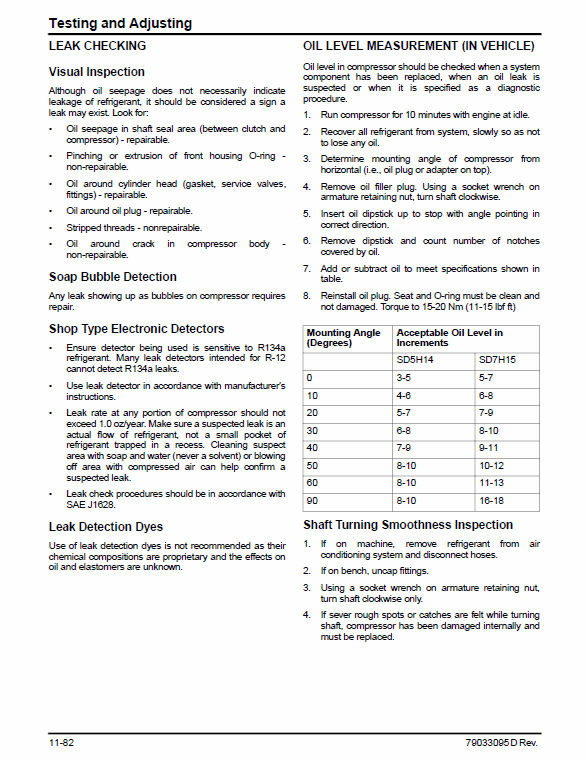

VISUAL INSPECTION

Do not check for leaks with your hands. Pin hole (very small) leaks can result in a high velocity oil stream that will be invisible close to hose. This oil can penetrate skin and cause personal injury.

Use cardboard or paper to locate pin hole leaks.

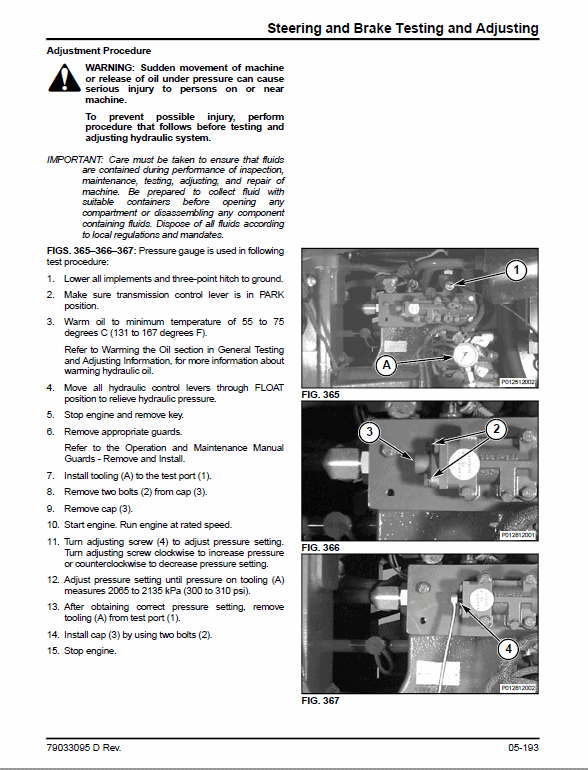

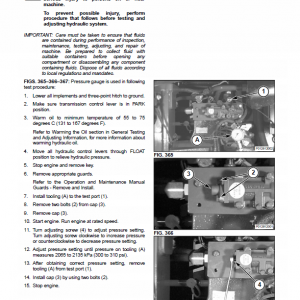

WARNING: Sudden movement of machine or release of oil under pressure can cause serious injury to persons on or near machine.

To prevent possible injury, perform procedure that follows before testing and adjusting hydraulic system.

Use following procedure to perform a visual inspection.

1. Move machine to a smooth horizontal location.

2. Lower all implements to ground and lower three-point hitch to ground.

3. Make sure that transmission control lever is in Park position.

4. Warm oil to a minimum temperature of 60 degrees C (140 degreesF), if necessary.

5. Move all hydraulic control levers through Float position to relieve hydraulic pressure.

6. Stop engine and remove key.

7. Remove appropriate guards.

Perform following visual inspections.

1. Measure oil level.

2. Check for air in oil that is in sump. Check immediately after stopping machine. Check sight gauge at rear of machine next to PTO shaft. Check for air bubbles in sight gauge.

3. Remove filter elements. Check for particles that are removed from oil by filter element. Use a magnet to separate metallic particles from nonmetallic particles.

Bronze colored particles give an indication of a clutch failure. Brass particles or shiny steel particles give indication of a pump failure. Rubber particles give an indication of a seal failure or hose failure.

4. Inspect all oil lines and connections for damage or leaks.

5. Inspect control linkages for broken components or for damaged components

Be the first to review “Challenger MT835C, MT845C, MT855C, MT865C, MT875C Tractor Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.