Case 9045B Excavator Service Manual

$34.00

Manual Included:

- Service Manual: 1129 pages

Specifications:

- Brand: Case

- Model:9045B

- Type: Excavator

- Manuals: Service Manual

- Publication Numbers: 7-11401 (Apr 1999)

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

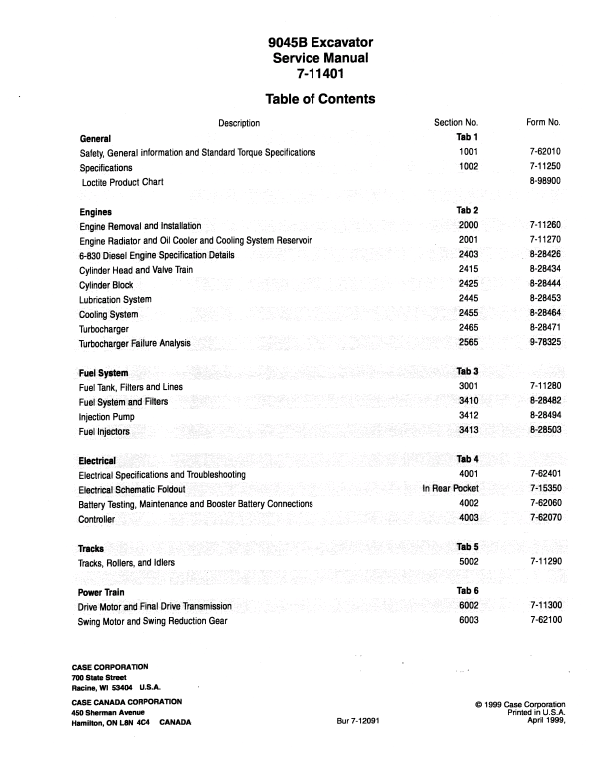

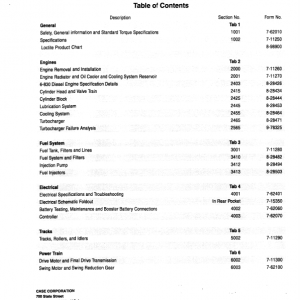

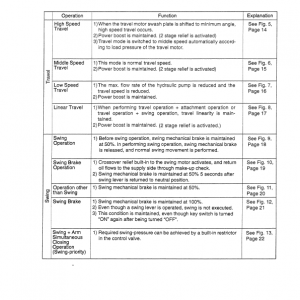

Table of Contents

1 General Information

2 Engine

3 Fuel System

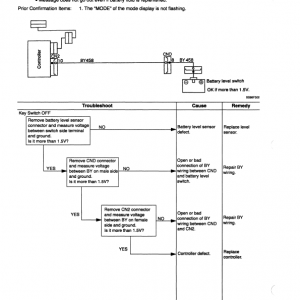

4 Electrical System

5 Tracks

6 Power Train

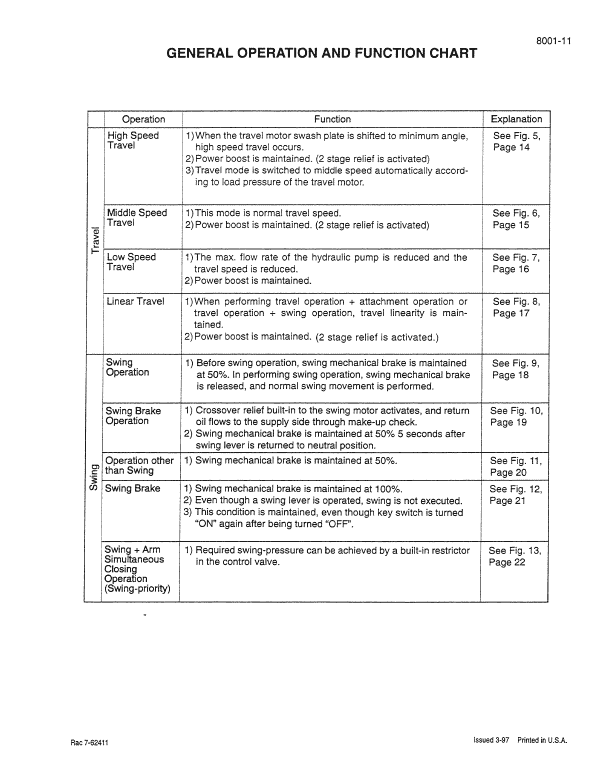

7 Hydraulics

8 Mounted Equipment

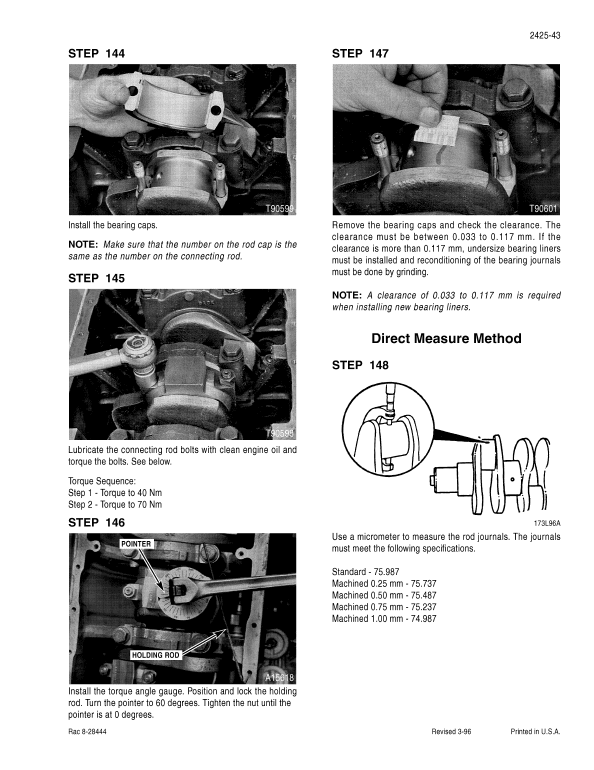

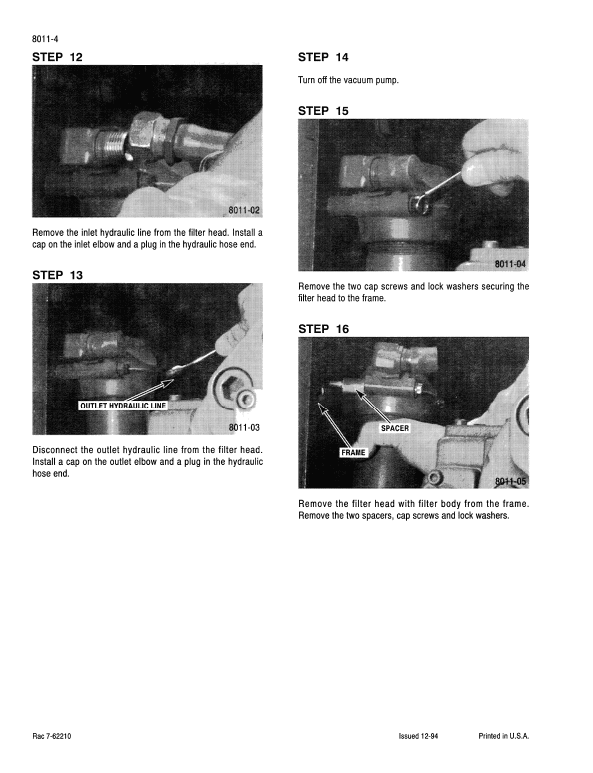

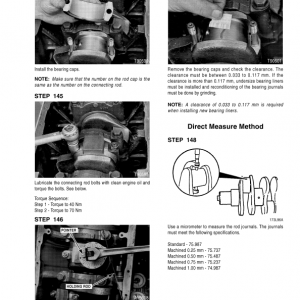

Manual Extract Cylinder Block Inspection

STEP 1

Clean all parts using suitable cleaning solvent. Dry using low pressure compressed air.

STEP 2

Inspect springs (2, 13, 25, and 29) for cracks, breaks, distortion, bent condition, or signs of permanent set. Replace a spring if defective.

STEP 3

Inspect cylinder block (4) for pitting, scoring, grooves, cracks, flaking of finish, or other damage. Check piston bores for wear indicated by damage to finish, scoring, or grooves.

Check splines for wear, cracks, or breaks. Replace cylinder block if any of these conditions are observed.

STEP 4

Check retainer holder (7), retainer plate (9), and valve plate (24) for pitting, scoring, grooves, cracks, breaks, flaking of finish, or other damage. Replace if any of these conditions are observed.

STEP 5

Check pistons (8 and 14) for pitting, scoring, grooves, cracks, flaking of finish, or other damage. Replace a piston if any defects are observed.

STEP 6

Inspect bearings (11 and 36) for flaking on the outer race.

Check bearings for rough rotation. Check outer and inner races for wear, chipping, nicks, flaking, or other damage.

Replace a bearing as necessary.

STEP 7

Inspect steel balls (12) for pitting, scores, cracks, out of roundness, or other defects. Check for wear at area where contact is made with swash plate (16); wear is indicated by damage to finish. Replace if any defects are observed.

STEP 8

Check shaft (15) for cracks, breaks, distortion, nicked or wom splines, or other damage. Replace shaft if any of these conditions are observed.

STEP 9

Inspect the swash plate (16) for pitting, scoring, cracks, breaks, or other damage. Check that ball (12) contact area on swash plate is not worn, cracked, or pitted. Replace the swash plate if any of these conditions are observed.

STEP 10

Inspect disk plates (18) for grooves or flaking. Replace as necessary.

STEP 11

Check friction plates (19) for cracks, distortion, broken or missing teeth, and grooves. Replace if any of these defects are observed.

STEP 12

Check brake piston (20) for cracks, breaks, chipping,

Be the first to review “Case 9045B Excavator Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.