Case 600, 660 Combine Trencher Repair Service Manual

$34.00

Manual Included:

- Service Manual: 693 pages

Specifications:

- Brand: Case

- Model: 600, 660

- Type: Combine Trencher

- Manuals: Service Manual

- Publication Numbers: 9-63801 (

- Language: English

- Format: PDF

- Description

- Reviews (0)

Description

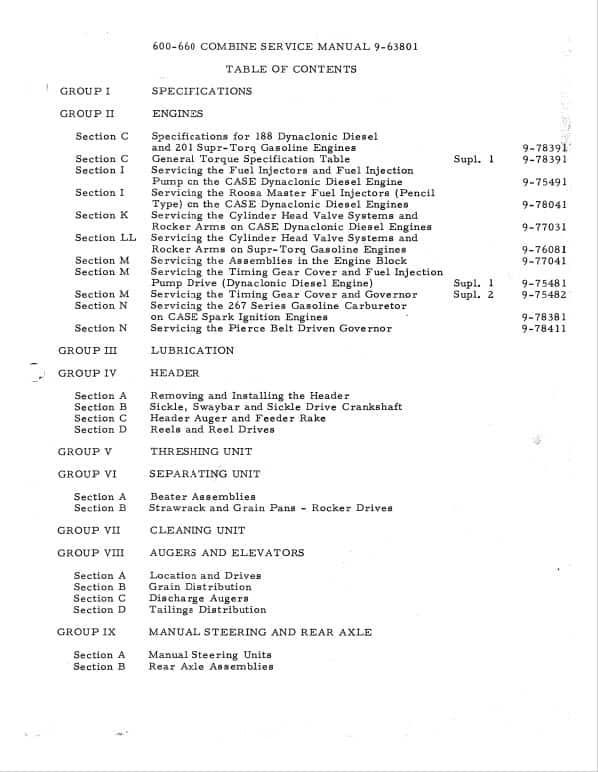

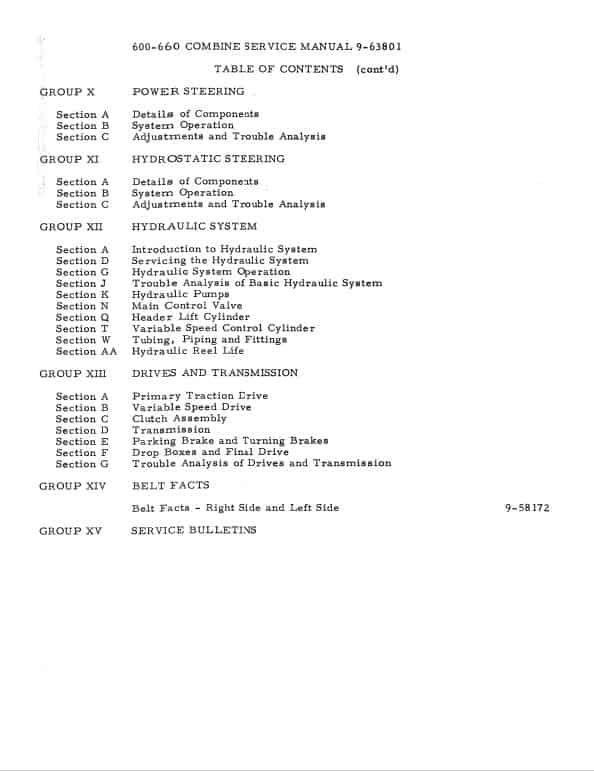

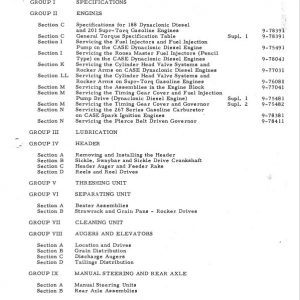

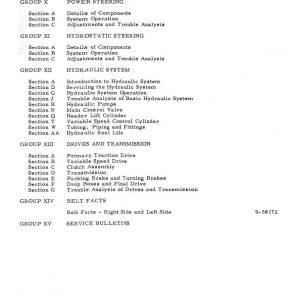

Table of Contents

- Specification

- Engines

- Lubrication

- Header

- Threshing Unit

- Separating Unit

- Cleaning Unit

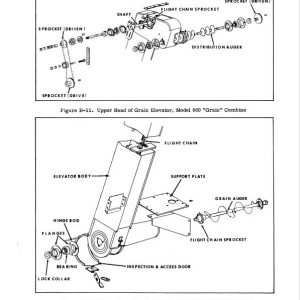

- Augers and Elevators

- Manual Steering and Rear Axle

- Power Steering

- Hydrostatic Steering

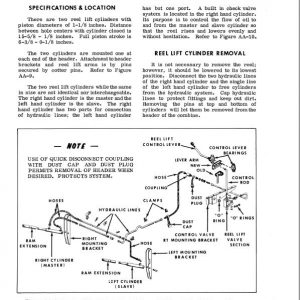

- Hydraulic System

- Drives and Transmission

- Belt Facts

- Service Bulletins

Manual Extract: Diesel particulate filter

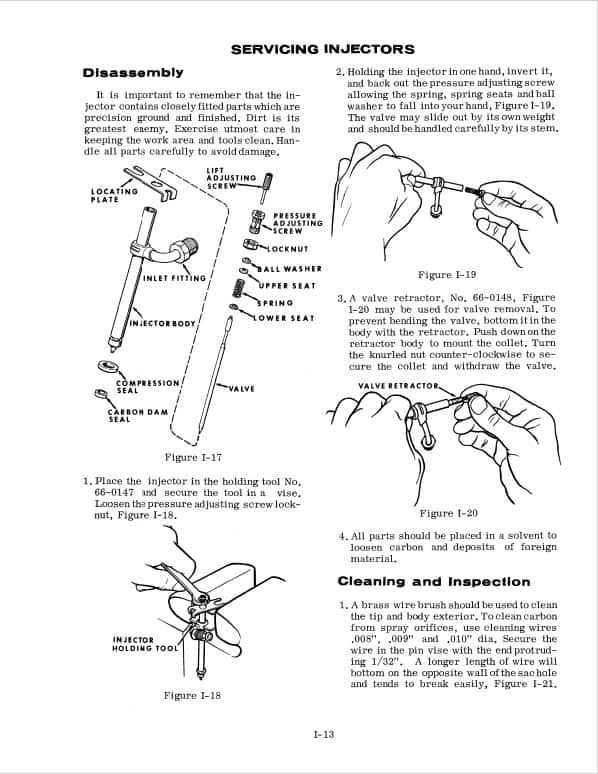

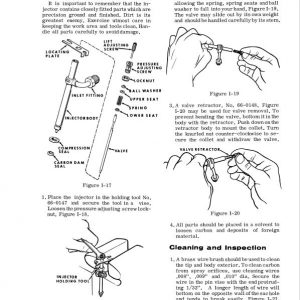

1. Open the gauge valve approximately one full turn. It is not necessary to fully open the gauge valve.

2. Operate the hand lever slowly and raise the pressure until the nozzle valve opens and fuel is sprayed. Observe the opening

pressure as indicated on the pressure gauge.

3. If the opening pressure is as specified in the “Specification “Section, it is not necessary to reset the pressure. NOTE When testing more than one injector out of a set in one engine, there must not be more than 100 pounds difference in pressure between any of the injectors. If there is, reset the opening pressure on the injector o r injectors that are closest to being above or below the recommended range.

4. Raise the pressure again until the nozzle valve opens. The instant the valve opens and fuel is sprayed, the pressure will drop

sharply. This is the initial drop and is caused by the nozzle valve opening and closing. The initial drop must not be less than 6 seconds at a temperature of 50 to 70° F . At a higher temperature, a somewhat lower figure will be obtained.

Note: Th e pressure will continue to lower slowly after the initial drop. Be careful not to confuse this with the sharp

initial drop.

5. Allow the pressure to drop and then slowly operate the hand lever again. Hold the pressure 100 pounds lower then specified

range and observe the end of the nozzle. The nozzle must remain dry at a pressure approximately 100 pounds lower than the recommended opening pressure. If a drop of fuel is observed forming at the nozzle valve projection, the valve is leaking.

6. While you are checking the opening pressure and the valve for leakage, observe the a mount of fuel that comes out of the leak-off connection on the holder body. A very small amount of fuel is required to lubricate the lapped surfaces of the nozzle valve and body. If excessive overflow from the leak-off connection is noted, the injector will require servicing.

Note: To determine what would be considered an excess flow from the leak-off connection, check a new injector assembly on the test stand.

Be the first to review “Case 600, 660 Combine Trencher Repair Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.