BT SPE125, SPE125L, SPE135S, SPE160, SPE200, SPE200L Pallet Truck Manual

$27.00

BT SPE125, SPE125L, SPE135S, SPE160, SPE200, SPE200L Pallet Truck Service Manual: 190 Pages

Publication 30076-040

English 2006

Format: PDF

- Description

- Reviews (0)

Description

BT SPE125, SPE125L, SPE135S, SPE160, SPE200, SPE200L Pallet Truck Manual

Pallet Truck Model: SPE125, SPE125L, SPE135S, SPE160, SPE200, SPE200L

Publication 30076-040

English 2006

Format: PDF

BT SPE125, SPE125L, SPE135S, SPE160, SPE200, SPE200L Pallet Truck Service Manual: 190 Pages

Pallet Truck Manual Table of Content:

- General product information

- Technical data

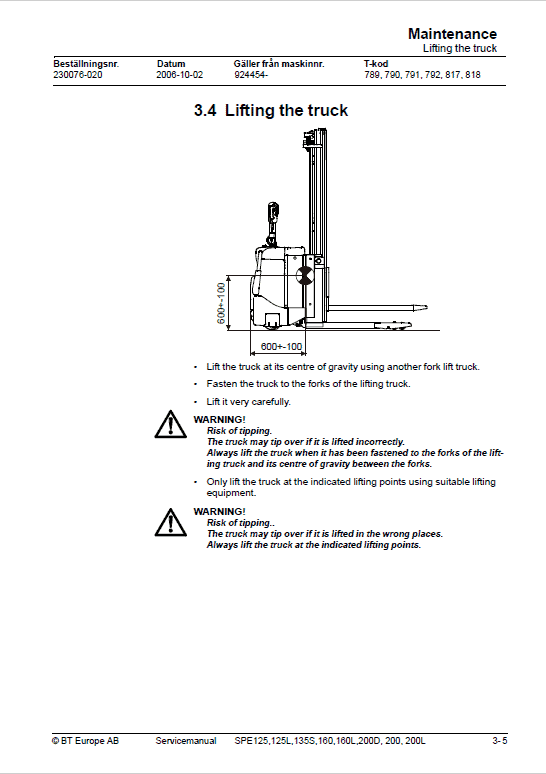

- Maintenance

- Oil and Grease

- Drive unit

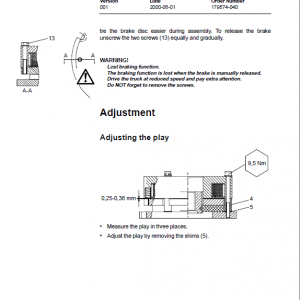

- Brake

- Display

- Hydraulic

- Wheels

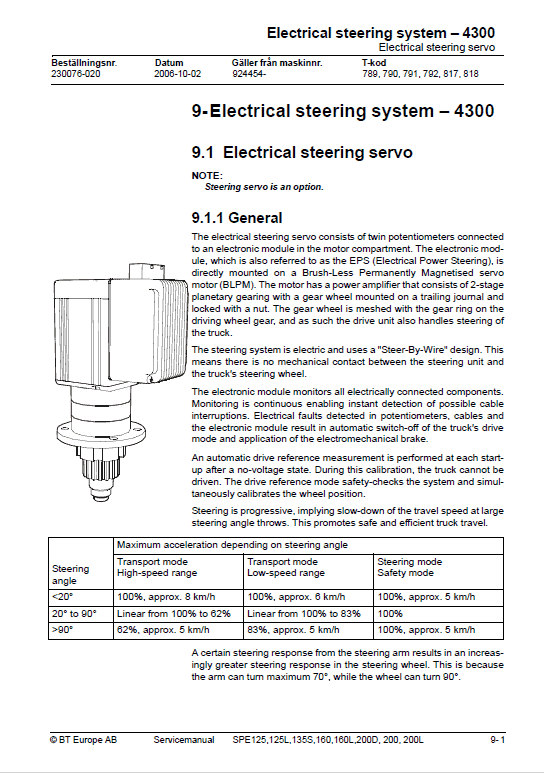

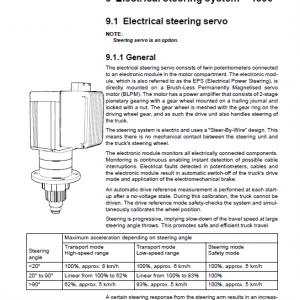

- Steering

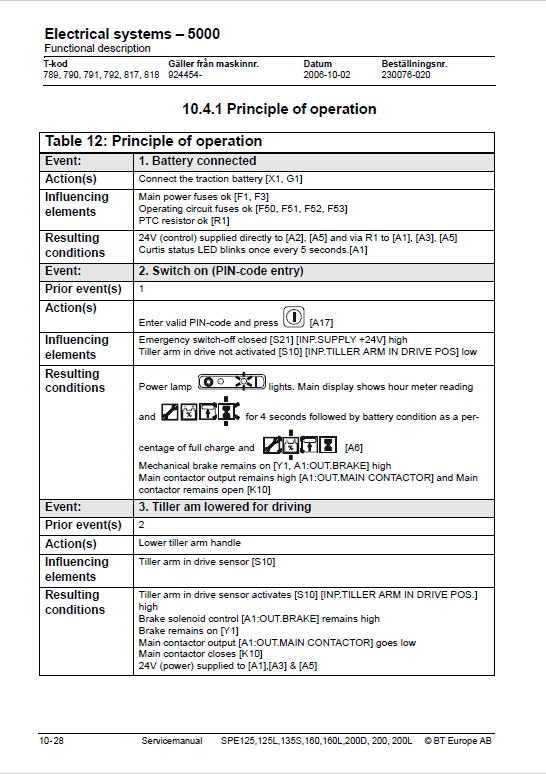

- Electrical

To assure maximum safety and minimum downtime, all items in the service programme should be covered. The service intervals are only guidelines and need not be strictly followed. The operator of the truck should adapt these to local requirements, however, it is important that the minimum requirements as stated by BT are observed.

Keep the motor as clean as possible since this is a decisive factor for correct operation. Regularly inspect the motor and motor compartment for build-up of dust, oil and other contaminants.

If the motor windings and internal compartments are dry, use a vacuum cleaner with a suitable nozzle to clean the motor. Compressed air can be used together with a vacuum cleaner for cleaning. If this is the case, make sure the compressed air is clean and dry.

If deposits have formed on the windings, use a lint-free cloth to remove them. If required, moisten the cloth with an organic, volatile grease solvent that will not damage the windings. However, do not use too much cleaning agent as it could penetrate into the motor parts.

If grease deposits are left on the surface, use a suitable solvent to remove cleaning agent remains.

If the motor components are heavily contaminated, it may be necessary to use a solvent that is sprayed onto the parts. It is especially important for the rotor that the cleaning agent is applied in a manner that avoids contaminants from penetrating into the motor section.

One method to clean the rotor is to submerge it in solvent. If this method is used, be sure to later dry the motor using a heat source. During the drying process, arrange good ventilation and allow the components to dry until repeated insulation resistance measurements show similar and approved values.

Be the first to review “BT SPE125, SPE125L, SPE135S, SPE160, SPE200, SPE200L Pallet Truck Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.