AGCO LT75, LT85, LT90, LT95 Tractor Workshop Repair Manual

$37.00

Manual for: AGCO LT Tractor

Format: PDF

Book Number: 3378583M5

English

Issued October 2007

AGCO LT75, LT85, LT90, LT95 Tractor Repair Service Manual : 1959 Pages

- Description

- Reviews (0)

Description

AGCO LT75, LT85, LT90, LT95 Tractor Workshop Service Manual

Manual for: AGCO LT Tractor

Format: PDF

Book Number: 3378583M5

English

Issued October 2007

AGCO LT75, LT85, LT90, LT95 Tractor Repair Service Manual : 1959 Pages

Manual TABLE OF CONTENTS

Introduction

Specification

Splitting the tractor

Engine

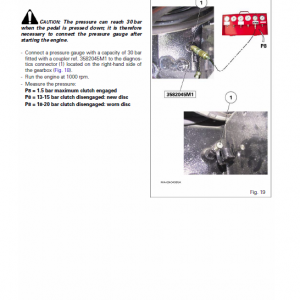

Clutch

Gearbox

Rear Axle

Power take off

Front Axle

Hydraulics

Electrical Equipment

Electronics

Cab and equipment

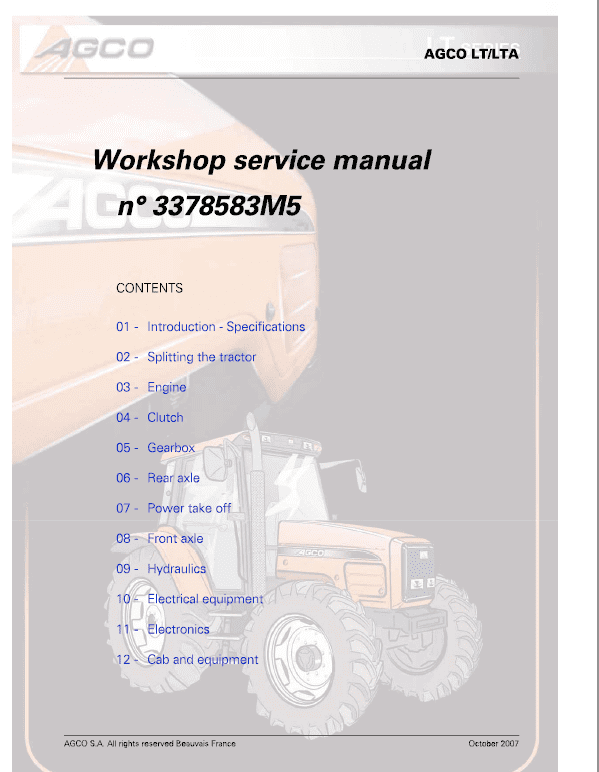

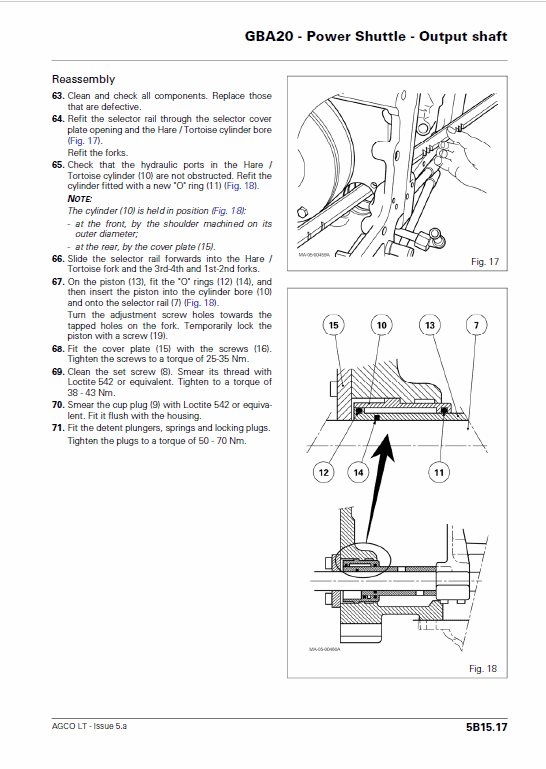

AGCO LT75, LT85, LT90, LT95 Manual Extract – Mechanical reverse shuttle

Construction

The GBA20 gearbox with mechanical reverse shuttle consists of three gear trains fitted to the: – layshaft;

– intermediate shaft (or main shaft), – output shaft.

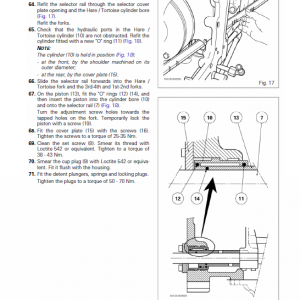

It allows eight basic synchronised gear ratios: – four gear ratios: 1st, 2nd, 3rd and 4th; – two range ratios: Hare and Tortoise.

Its main characteristic is its assembly of three single cone synchronisers.

The main gearbox consists of four synchronised gears.

A gear idle-mounted to the output shaft and controlled by a synchroniser allows the four initial gears to be doubled to obtain the eight basic gears.

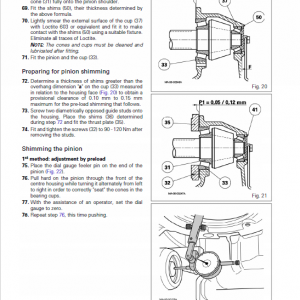

The layshaft and the intermediate shaft are supported by tapered roller bearings.

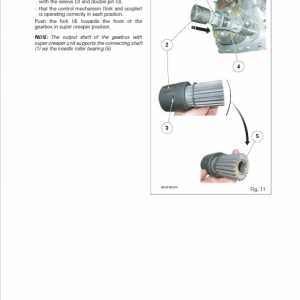

The output shaft is fitted on two tapered roller bearings and one needle roller bearing.

The layshaft bearing cups are fitted up against the housing.

All gears have helical teeth and are constantly meshed.

To ensure optimum gearbox reliability, the bearings are fitted:

– with preload for the layshaft,

– with clearance for the intermediate shaft.

The output shaft may be set either with a slight clearance or a slight preload.

Be the first to review “AGCO LT75, LT85, LT90, LT95 Tractor Workshop Repair Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.