Sumitomo SH235X-6 Hydraulic Excavator Repair Service Manual

$42.00

Sumitomo Excavator SH235X-6

Format: PDF

Manual Identification: WLSM2356-00T, WDL2356-1T

English

Jan. 2015

- Sumitomo SH235X-6 Hydraulic Excavator Repair Service Manual – 1370 Pages

- Operators Manual – 270 Pages

- Parts Catalog – 642 Pages

- Description

- Reviews (0)

Description

Sumitomo Excavator SH235X-6

Format: PDF

Manual Identification: WLSM2356-00T, WDL2356-1T

English

Jan. 2015

- Sumitomo SH235X-6 Hydraulic Excavator Repair Service Manual – 1370 Pages

- Operators Manual – 270 Pages

- Parts Catalog – 642 Pages

Sumitomo SH235X-6 Manual TABLE OF CONTENTS

Safety, general information and standard torque data…………………………………………… 4

General Information…………………………………………………………………………………………. 5

Standard Torque Data For Cap Screws And Nuts………………………………………………. 12

Specifications And Special Torque Settings………………………………………………………. 13

Abbreviation………………………………………………………………………………………………….. 14

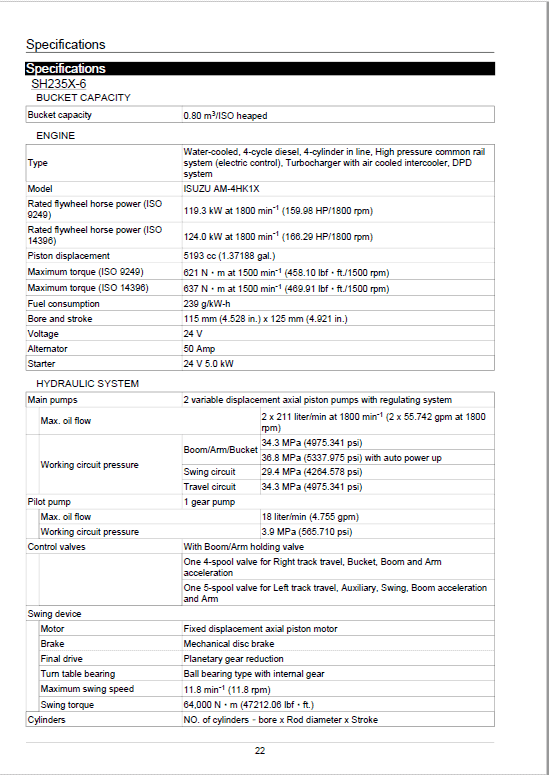

Specifications………………………………………………………………………………………………… 22

Main Equipment Table……………………………………………………………………………………. 32

Overall View………………………………………………………………………………………………….. 49

WORK RANGE DIAGRAM……………………………………………………………………………… 53

Main Unit Weight…………………………………………………………………………………………… 61

FLUIDS AND LUBRICANTS……………………………………………………………………………. 80

Circuits and Operation explanation…………………………………………………………………… 83

Main Equipment Structure and Operation Explanation………………………………………… 86

Hydraulic Pump…………………………………………………………………………………………….. 87

Travel Motor………………………………………………………………………………………………… 102

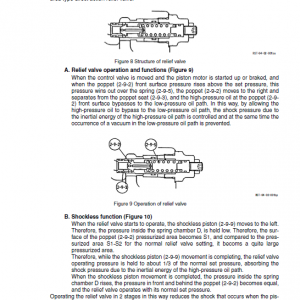

Swing Motor………………………………………………………………………………………………… 115

Control Valve………………………………………………………………………………………………. 121

5 Stack Solenoid Valve Operation Explanation………………………………………………… 156

Upper Pilot Valve (remote control valve)…………………………………………………………. 158

Travel Pilot Valve (remote control valve)…………………………………………………………. 163

Cushion Valve …………………………………………………………………………………………….. 168

3 Stack Proportional Valve (for pilot)………………………………………………………………. 174

Engine Summary…………………………………………………………………………………………. 178

Hydraulic Equipment Layout………………………………………………………………………….. 248

Overall view………………………………………………………………………………………………… 249

Port Diagram……………………………………………………………………………………………….. 254

Hydraulic Device………………………………………………………………………………………….. 279

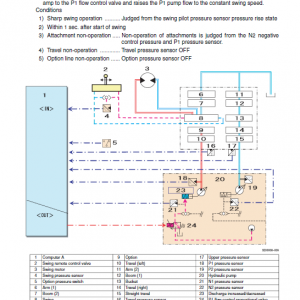

Electrical and Engine Functions and Service Support……………………………………….. 280

Basic Functions…………………………………………………………………………………………… 281

Service Support…………………………………………………………………………………………… 356

Cautions for Maintenance……………………………………………………………………………… 397

Electrical Equipment Layout Diagram……………………………………………………………… 409

Connection Connector Pin Layout………………………………………………………………….. 439

Sequence Circuit Diagram…………………………………………………………………………….. 442

Removal / Installation and Assembly / Disassembly………………………………………… 457

Pressure Bleeding Operations……………………………………………………………………….. 464

Removal and Installation of Track………………………………………………………………….. 465

Removal and Installation of Shoe Assembly……………………………………………………. 466

Removal and Installation of Shoe Plate…………………………………………………………… 469

Removal and Installation of Roller………………………………………………………………….. 470

Removal and Installation of Upper Roller………………………………………………………… 471

Assembly and Disassembly of Upper Roller…………………………………………………….. 473

Assembly and Disassembly of Lower Roller…………………………………………………….. 482

Removal and Installation of Drive Sprocket……………………………………………………… 488

Removal and Installation of Take-up Roller……………………………………………………… 490

Assembly and Disassembly of Take-up Roller…………………………………………………. 492

Removal and Installation of Grease Cylinder…………………………………………………… 500

Assembly and Disassembly of Tension Shock Absorber…………………………………… 502

Removal and Installation of Center Joint…………………………………………………………. 505

Assembly and Disassembly of Center Joint…………………………………………………….. 509

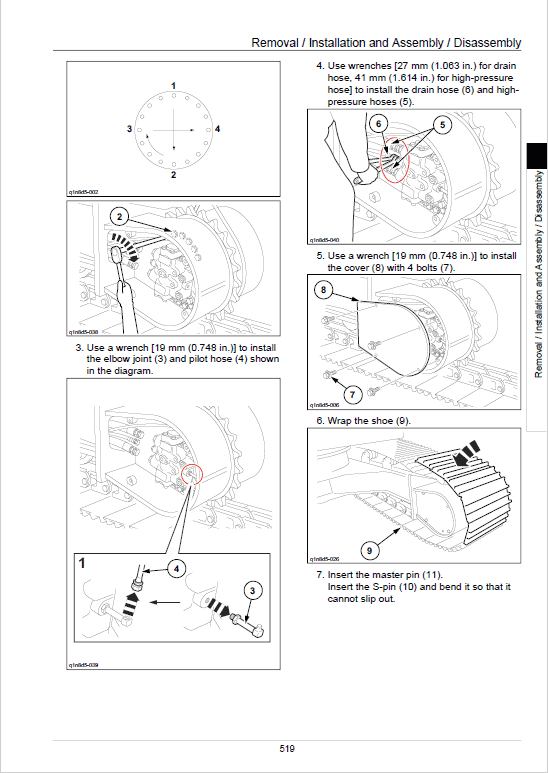

Removal and Installation of Travel Motor………………………………………………………… 516

Assembly and Disassembly of Travel Motor…………………………………………………….. 521

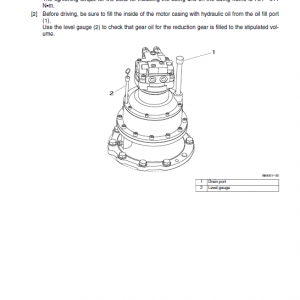

Removal and Installation of Swing Unit…………………………………………………………… 570

Assembly and Disassembly of Swing Motor…………………………………………………….. 574

Assembly and Disassembly of Swing Unit……………………………………………………….. 588

Removal and Installation of Hydraulic Pump……………………………………………………. 593

Procedures for Assembly and Disassembly of Hydraulic Pump Main Unit……………. 599

Pump Main Unit Maintenance Standards………………………………………………………… 604

Removal and Installation of Control Valve……………………………………………………….. 630

Procedures for Assembly and Disassembly of Control Valve……………………………… 635

Removal and Installation of Engine Assembly………………………………………………….. 657

Removal and Installation of Fuel Cooler, Engine Intercooler, Radiator, and Oil

Cooler………………………………………………………………………………………………………… 663

Removal and Installation of Turbo Charger……………………………………………………… 674

Removal and Installation of EGR Valve…………………………………………………………… 678

Removal and Installation of Top Cover……………………………………………………………. 682

Removal and Installation of Muffler………………………………………………………………… 683

Removal and Installation of Cylinder Head Cover…………………………………………….. 685

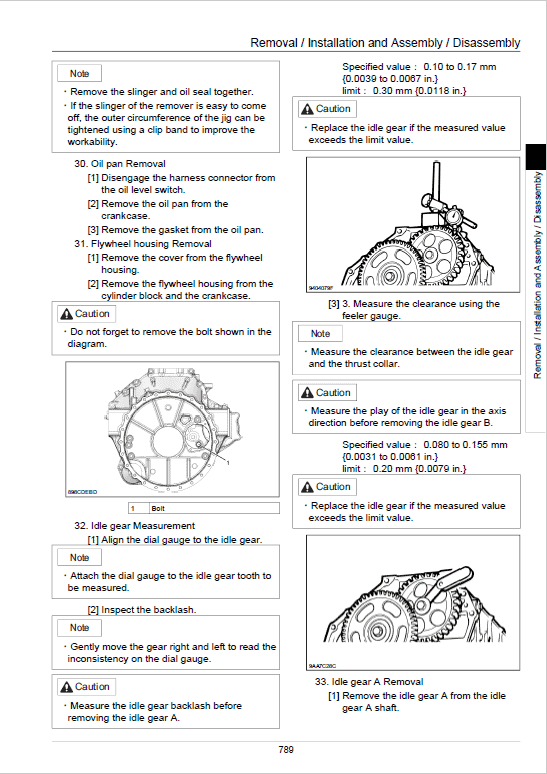

Removal and Installation of Cylinder Block……………………………………………………… 727

Lubrication System………………………………………………………………………………………. 777

Cooling System……………………………………………………………………………………………. 816

Removal and Installation of Exhaust Manifold………………………………………………….. 824

Disassembly, Removal and Installation of DPD Assembly…………………………………. 831

Removal and Installation of Fuel Supply Pump………………………………………………… 836

Removal and Installation of Common Rail Assembly………………………………………… 840

Removal and Installation of Injector………………………………………………………………… 847

Removal and Installation of Starter Motor……………………………………………………….. 856

Removal and Installation of Alternator…………………………………………………………….. 858

Preheating System………………………………………………………………………………………. 860

Removal and Installation of Fuel Tank……………………………………………………………. 872

Removal and Installation of Hydraulic Tank…………………………………………………….. 875

Removal and Installation of Pilot Blocs……………………………………………………………. 879

Removal and Installation of Travel Remote Control Valve…………………………………. 880

Procedures for Assembly and Disassembly of Travel Remote Control Valve……….. 883

Removal and Installation of Operation Remote Control Valve……………………………. 896

Procedures for Assembly and Disassembly of Operation Remote Control Valve….. 904

Removal and Installation of Blade Remote Control Valve………………………………….. 915

Assembly and Disassembly Procedures…………………………………………………………. 918

Removal and Installation of 5 Stack Solenoid………………………………………………….. 926

Removal and Installation of Cushion Valve……………………………………………………… 930

Assembly and Disassembly of Cushion Valve………………………………………………….. 933

Removal and Installation of Operator’s Seat……………………………………………………. 937

Removal and Installation of Cab Assembly……………………………………………………… 938

Removal and Installation of Wiper………………………………………………………………….. 942

Removal and Installation of Wiper Controller…………………………………………………… 943

Removal and Installation of Wiper Motor…………………………………………………………. 944

Removal and Installation of ECM…………………………………………………………………… 946

Removal and Installation of Computer A…………………………………………………………. 947

Removal and Installation of Computer B…………………………………………………………. 948

Removal and Installation of Monitor……………………………………………………………….. 949

Removal and Installation of Cab Front Glass…………………………………………………… 951

Window Lock Adjustment Procedures…………………………………………………………….. 953

Tightening torque…………………………………………………………………………………………. 955

Removal and Installation of Counterweight……………………………………………………… 956

Removal and Installation of Bucket………………………………………………………………… 960

Removal and Installation of Bucket Link………………………………………………………….. 962

Removal and Installation of Arm…………………………………………………………………….. 964

Removal and Installation of Boom………………………………………………………………….. 966

Removal and Installation of Blade………………………………………………………………….. 971

Removal and Installation of Bucket Cylinder……………………………………………………. 974

Removal and Installation of Arm Cylinder………………………………………………………… 977

Removal and Installation of Boom Cylinder……………………………………………………… 981

Removal and Installation of Blade Cylinder……………………………………………………… 986

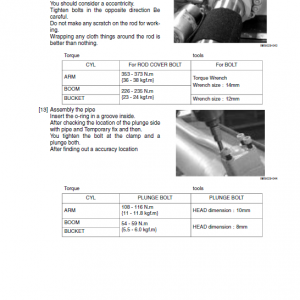

Procedures for Operation/Assembly and Disassembly of Hydraulic Cylinder

(made by KYB)……………………………………………………………………………………………. 990

Removal and Installation of HBCV……………………………………………………………….. 1025

List of special tools…………………………………………………………………………………….. 1028

Maintenance standards and Measurement procedures………………………………….. 1051

Pressure Measurement and Adjustment Procedures………………………………………. 1052

Hydraulic Pump Flow Measurement Procedures……………………………………………. 1068

Drain Volume Measurement Procedures……………………………………………………….. 1072

Air Bleed Procedure……………………………………………………………………………………. 1075

Maintenance Standards………………………………………………………………………………. 1079

Bolt Size and Torque Table…………………………………………………………………………. 1095

New Machine Performance Judgment Table………………………………………………….. 1100

Air Conditioning…………………………………………………………………………………………… 1109

Air Conditioner Overall Diagram…………………………………………………………………… 1110

Assembly and Disassembly of Unit………………………………………………………………. 1152

Removal and Installation of Compressor……………………………………………………….. 1157

Removal and Installation of Condenser…………………………………………………………. 1158

Removal and Installation of Receiver Dryer…………………………………………………… 1160

Work Precautions………………………………………………………………………………………. 1162

Troubleshooting…………………………………………………………………………………………… 1173

Engine-side Diagnostic Trouble Code List……………………………………………………… 1177

Main Unit-side Diagnostic Trouble Code List………………………………………………….. 1179

Engine-side Trouble……………………………………………………………………………………. 1181

Main Unit-side Trouble………………………………………………………………………………… 1254

Symptom…………………………………………………………………………………………………… 1345

Data Reference Values……………………………………………………………………………….. 1359

The Sumitomo Manual Preface

The purpose of this Sumitomo Excavator manual is to assist dealers and repair serviceman in efficient repair and maintenance of their machinery. Carrying out the procedures as detailed, together with the use of any special tools needed.

Using the Sumitomo SH235X-6 Manual

To make information easier to find, there is an index at the beginning of each section listing the various parts in that section. At the beginning of each part there is a table of contents which should also be used as a guide to locate information.

To assist with locating information, each section of the manual is preceded by a contents page listing the repair operations, Each instruction within an operating has a sequence number. To complete the operation in the minimum time is possible follow the manual guideline and repair instructions.

When parts have to be replaced in either the SH235X-6 Hydraulic Excavator , it is essential that only genuine Sumitomo parts should be used. Special attention should be paid to the following points concerning repairs and the fitting of replacement parts and accessories.

Indexing

For convenience the manual is divided into section and parts, each page bearing a section and part number. The sections are subdivided into numbered operation. This simplifies cross referencing and enable the subject to be found easily.

Be the first to review “Sumitomo SH235X-6 Hydraulic Excavator Repair Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.