Takeuchi TL250 Compact Loader Service Manual

$36.00

Takeuchi TL250 Service Repair Manual – 548 Pages

Takeuchi TL250 Operators Manual – 213 Pages

Parts Manual – 451 Pages

Engine Manual for V3800DI-T-E3B-TLTU-1 (KUBOTA) -106 Pages

- Description

- Reviews (0)

Description

Takeuchi TL250 Compact Loader Service Manual

Type: Loader TL250

Format: PDF

Language of the Service and Operating Manual: English & French

Takeuchi TL250 Service Manual – 548 Pages

Takeuchi TL250 Operators Manual – 213 Pages

Parts Manual – 451 Pages

Engine Manual for V3800DI-T-E3B-TLTU-1 (KUBOTA) -106 Pages

For All applicable S/N

The manual describes operation, service, repair and maintenance of the Loader, as well as safety instructions that should be follow.

The Takeuchi TL250 manual is intended for persons who engage in maintenance operations, and explains procedures for disassembly and reassembly of the machine, check and maintenance procedures, maintenance reference values, troubleshooting and outline specifications, etc. Please use this Takeuchi manual for Loader TL250 as a reference in service activities to improve maintenance techniques.

Please note that the contents and diagrams included in this manual may not match your machine exactly.

Items or diagram which manual contains are subject to change without notice due to design modifications, etc. Always store the Takeuchi Loader manual near at hand preferably on the machine itself. When transferring ownership of this machine, be sure to provide the owner manual to the next owner.

Table of Content of TL250 Instructions Manual:

I . GENERAL

II . SPECIFICATIONS

III. MACHINE CONFIGURATION

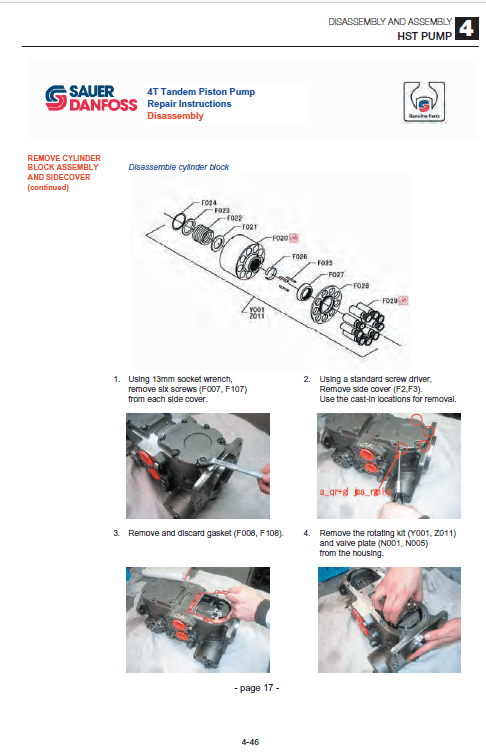

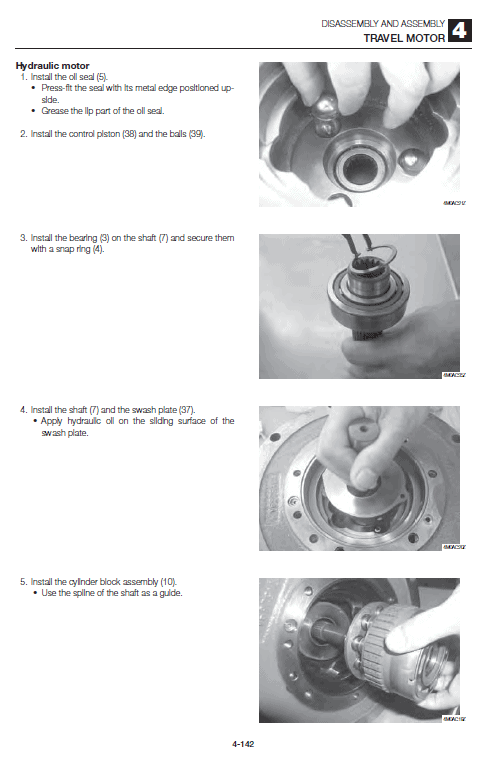

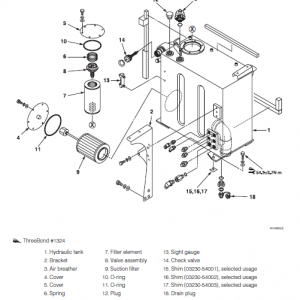

IV. HYDRAULIC UNITS

V . TROUBLESHOOTING

VI. ENGINE

Before operating, perform the prescribe inspections and make repairs immediately should any irregularities be found. If a failure that causes loss of control such as steering, service brakes or engine occurs, stop the machine motion as quickly as possible, follow the shutdown procedure, and keep machine securely park until the problem is fixed.

Extract from the Service Manual:

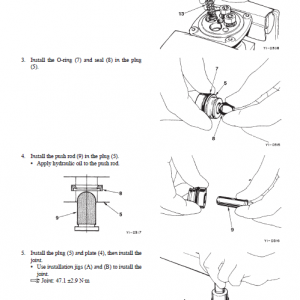

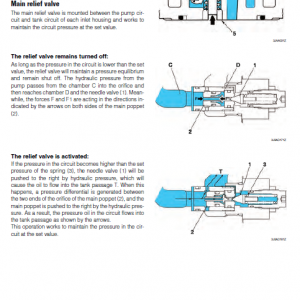

1. Check the load check valve on the control valve.

a. Disconnect the hose connecting the control valve and the arm cylinder from the control valve.

b. Connect the hose just disconnected to the bucket block.

c. Move the lever (bucket) to operate the arm cylinder.

If the arm cylinder operates normally, the load check valve (1) must be faulty.

Before starting the work above, lower the lift arm and bring the bucket down to the ground.

When the spool first draws, the oil pressure is low and the flow rate is small. Therefore, if the load check valve is faulty, the oil temporarily flows backward due to the load applied to the arm cylinder. As a result, the lift arm temporarily drops.

2. Check for leak inside the arm cylinder.

If the oil is flowing from the head side (A) to the rod side (B) due to the faulty arm cylinder piston or the tube, the lift arm temporarily drops because of the low oil pressure and small flow rate at the beginning of the spool drawing. Also, the cylinder has insufficient drive power.

However, the amount of spontaneous drop is large in this case.

Be the first to review “Takeuchi TL250 Compact Loader Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.