Linde Type 322, 323, 324 Forklift Model: E10, E12, E14, E15, E16, E20, E25, E30 Workshop Service Manual

$33.00

Linde Type 322, 323, 324 Forklift Model E10, E12, E14, E15, E15S, E16, E16S, E20, E25, E30 , E16P Workshop Repair Manual

This manual cover the Linde Type 322, 323, 324 Model :

E10,

E12,

E14,

E15,

E15S,

E16,

E16P,

E16S,

E20,

E25,

E30

Language: English, Format: PDF

- Description

- Reviews (0)

Description

Linde Type 322, 323, 324 Forklift Model E10, E12, E14, E15, E15S, E16, E16S, E20, E25, E30 , E16P Workshop Service Manual

This manual cover the Linde Type 322, 323, 324 Model :

E10,

E12,

E14,

E15,

E15S,

E16,

E16P,

E16S,

E20,

E25,

E30

Language: English, Format: PDF

1. Service Training manual PULSE CONTROL IV FOR TRAVEL DRIVE IN LINDE FORK LIFT TRUCKS, 80 Pages

2. Service Training manual for E12, E15, E15S, E16S Trucks, 78 pages

3. PULSE CONTROL FOR WORKING HYDRAULICS LINDE E-FORK LIFT TRUCKS, 38 Pages

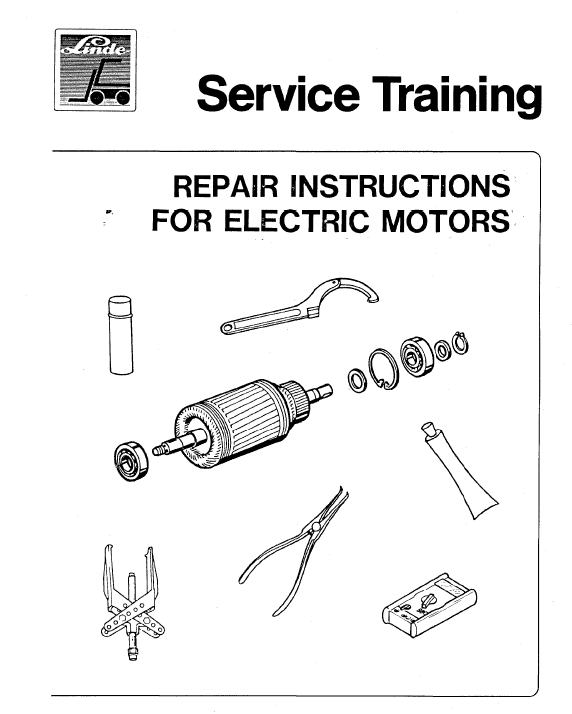

4. REPAIR INSTRUCTION FOR ELECTRIC MOTORS, 42 Pages

5. Indicating Instruments and Electrical Optional Equiments, 17 pages

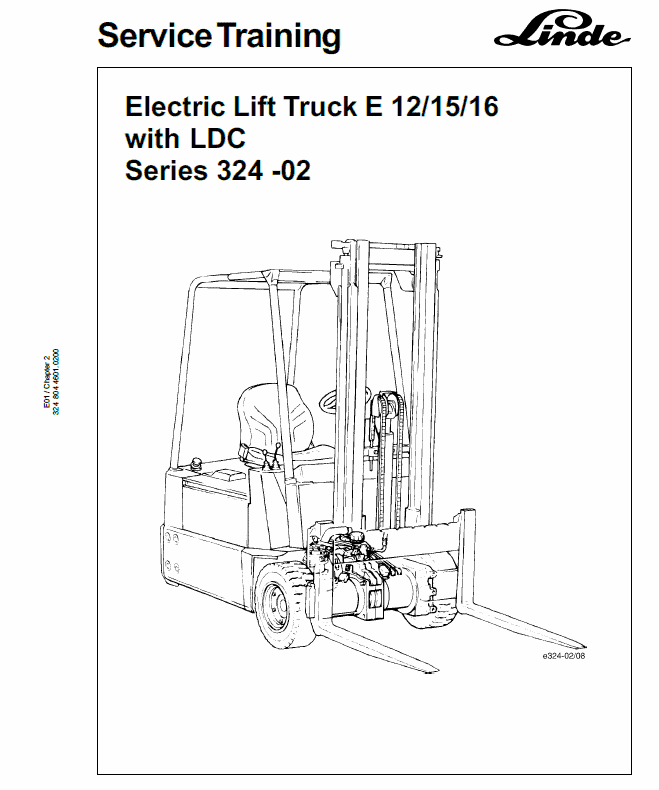

6. Electric Lift Truck E12/E15/E16 with LDC Series 324, 99 pages

7. Service Training manual for E12P, 26 pages

8. Operating Instructions Directive No. 94/9/EC Machine Group II Zones 1 + 2, Machine Categories 2G/3G

Zones 21, 22, Machine Categories 2D/3D, 90 pages

9. Technical Data, 1 pages

10. E12 – 02 / E15 – 02 / E16 – 02 Linde Fork Lift Truck Operating Instructions

11. Service Training Linde Electric Forklift Truck E16 Type 324 Explosion Protected zone 1,2 , 140 pages

Structure of training manual

This training manual document is based on the relevant seminar held the Linde training centres or at the authorised dealer’s premises. The repair manual document is divided into numbered sections from 0 to 10, with the content being identical in all training manual documents with a slight variation for some models. Ensure that Repair and maintenance of the Linde Type 322, 323, 324 Forklift Model: E10, E12, E14, E15, E16, E20, E25, E30 is in accordance with this training manual to prevent any damage.

Service Manual Content:

- Product information Motor

- Wheel drive

- Vehicle structure

- Undercarriage

- Operating elements

- Electrics / Electronics

- Hydraulics

- Load lift system

- Content

- Special equipment and accessories

- Diagrams

Furthermore, the training manual document is based on a modular concept and is in such a way it sequentially describes the structure of the truck. Thus in the different sections the individual vehicle components are described as independent units one after the other. This repair manual document is an extension of the existing training document for non-explosion protected versions of the internal combustion engine forklift Type 322, 323, 324. The introduction is followed by a complete table of contents for the training manual. This is sup plemented by an index at the end of the training manual.

You can also check our collections of Linde Manual Here.

You can also buy this Linde Type 322, 323, 324 Forklift Model: E10, E12, E14, E15, E16, E20, E25, E30 manual at our Sellfy Store:

https://sellfy.com/p/6HUZ/

Be the first to review “Linde Type 322, 323, 324 Forklift Model: E10, E12, E14, E15, E16, E20, E25, E30 Workshop Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.