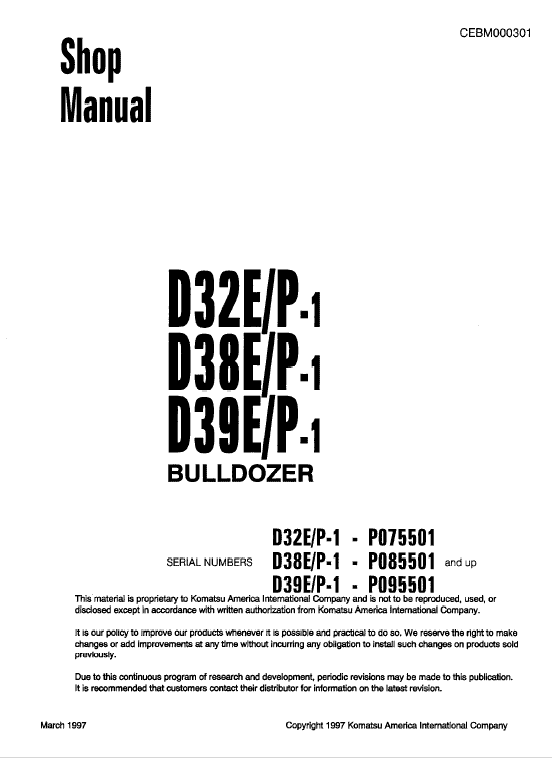

Komatsu D32E-1, D38E-1, D39E-1 Dozer Service Manual

$34.00

Language: English

Publication: CEBM004302 and CEBM003100

Format: PDF

Komatsu D32E-1, D38E-1, D39E-1 Service Repair Manual – 620 Pages

Komatsu D32E-1, D38E-1, D39E-1 Service Repair Manual – 636 Pages

- Description

- Reviews (0)

Description

Komatsu D32E-1, D38E-1, D39E-1 Dozer Service Manual

Komatsu Dozer Bulldozer D32E-1, D38E-1, D39E-1 Model

Language: English

Publication: CEBM004302 and CEBM003100

Format: PDF

Komatsu D32E-1, D38E-1, D39E-1 Service Manual – 620 Pages

Komatsu D32E-1, D38E-1, D39E-1 Service Manual – 636 Pages

Table of Content of the Komatsu Dozer D32E-1, D38E-1, D39E-1 Manual:

This shop manual includes information for locations,

INTRODUCTION SECTION 1 specifications, service/special tools, tolerances, pressures, lubricants and sealants, special torques, tests and adjustments, assembly tips and service bulletin references for various components of the machine. This shop manual is divided into major sections. These sections are indexed by title and divided by individual section index tab. To use this shop manual, locate the section required and turn to that section index tab.

MISCELLANEOUS SECTION 2

COOLING SECTION 6

DRIVE TRAIN SECTION 7

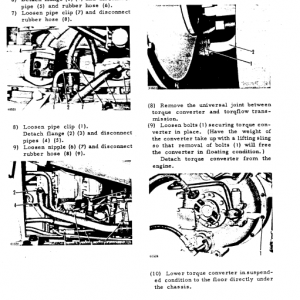

TORQUE CONVERTER SECTION 7B

TRANSMISSION SECTION 7C

STEERING DRIVE SECTION 7E

SPROCKET DRIVE SECTION 7F

ELECTRICAL SECTION 8

HYDRAULICS SECTION 10

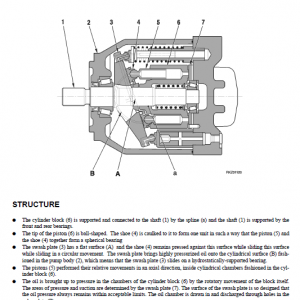

PUMPS AND MOTORS SECTION 10A

CONTROL VALVE SECTION 10B

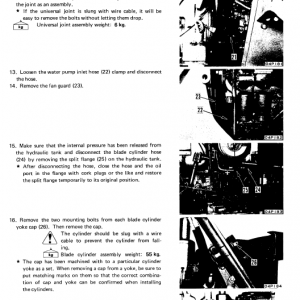

CYLINDERS SECTION 10C

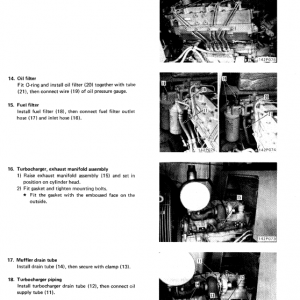

POWER SECTION 12

UNDERCARRIAGE SECTION 14

TRACK CHAIN SECTION 15

MOUNTED EQUIPMENT SECTION 17

STRUCTURE, FUNCTION & MAINTENANCE STANDARDS

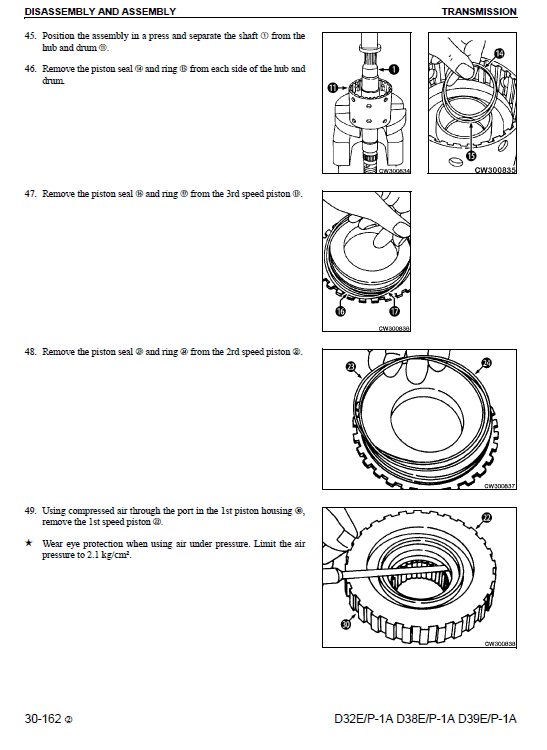

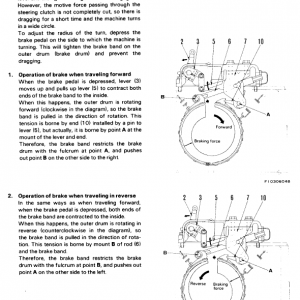

The transmission is designed to provide high speed shifting by use of hydraulically actuated clutch packs. It has three forward and three reverse speeds. Gears are mounted on four shafts; directional (input) shaft, range (output) shaft, countershaft and reverse idler shaft. The output shaft and pinion gear of the transmission F transmits power to the bevel gear carrier in the rear main frame.

• In the steering drive, power transfer is from the bevel gear and carrier assembly through the clutch and brake discs I and J to the planet gear carriers out the final drive 1) pinion shaft to the sprockets 1! and on to the tracks. In normal mode, the clutch discs are held stationary by the clutch shoes allowing the planet gear to walk around the clutch disc sun gear carrying the planet gear carriers with them.

• In a turn, the clutch disc on the side to which the turn is made is released from the clutch shoe. When the clutch disc is released, the planet gears rather than turning the planet gear carrier, rotate freely on their respective shafts and transfer motion to the free clutch disc.

At this time, the track on this side of the machine is just being carried along the ground. When the track is held stationary, the clutch disc is still free and the transfer of motion is to the free clutch disc as before only now the brake disc is held by the brake shoe preventing the sprocket drive pinion shaft from turning.

Be the first to review “Komatsu D32E-1, D38E-1, D39E-1 Dozer Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.