JCB Vibromax 253, 263 Tandum Roller Service Manual

$26.00

Model: Vibromax 253, 263

Language: English

Format PDF

Type: Service Repair Manual

JCB Vibromax 253, 263 Tandum Roller Service Repair Manual – 174 Pages

- Description

- Reviews (0)

Description

JCB Vibromax 253, 263 Tandum Roller Service Manual

Model: Vibromax 253, 263

Language: English

Format PDF

Type: Service Manual

JCB Vibromax 253, 263 Tandum Roller Service Manual – 174 Pages

The Vibromax 253 Series vibratory roller is a new from the ground up machine, replacing the 252. The 253 is a 2.5 metric ton, tandem drum machine with articulated steering, hydrostatic drive and a hydraulically driven vibration system and has a 1000 mm (39 inch) drum width while the Vibromax 263 is the 1200 mm (47 inch) drum width version.

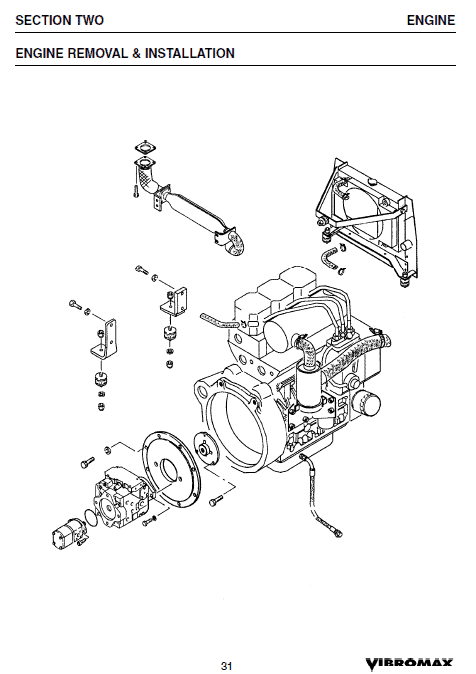

A Kubota D1403B, water cooled, three cylinder in-line diesel engine, mounted in the rear chassis, provides the power for the machine. The engine has a 29.0 Net Horse Power rating at 2600 RPM.

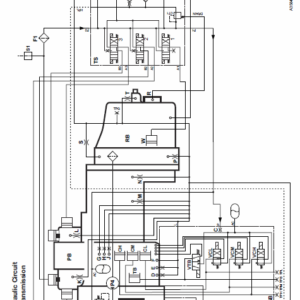

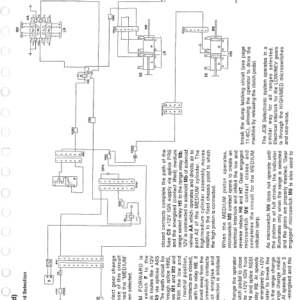

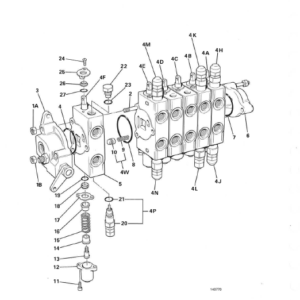

A Sauer Sunstrand variable displacement hydrostatic pump, used for machine propulsion, is mount to the flywheel end of the engine. It provides oil for the front and rear Poclain, fixed displacement, drum drive motors in a parallel path. The motors are located on the right hand side of the drums and are connect directly to the drum, without gear reduction.The vibration system consists of a fixed displacement gear pump mounted to the back of the propulsion pump. This gear pump drives the two gear motors (one on each drum, lefthand side) in a series flow path, with options of vibration to the front drum only, rear drum only, both drums or neither drum. Oil from the vibration circuit passes through an air to oil cooler at the engine radiator. The exciter shafts and the drum bearings are oil lubricated, eliminating the need for grease zerks.

Be the first to review “JCB Vibromax 253, 263 Tandum Roller Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.