Case CX160B, CX180B Crawler Excavator Service Manual

$35.00

Case CX160B, CX180B Excavator Service Manual – 1548 Pages

Case CX160B Schematic Set Excavator Service Manual – 535 Pages

Publication Number: SM160BTOC

English

July 2009

Format: PDF

- Description

- Reviews (0)

Description

Case CX160B, CX180B Excavator Manual

Excavator Model: CX160B and CX180B

Publication Number: SM160BTOC

English

July 2009

Format: PDF

Case CX160B, CX180B Excavator Service Manual – 1548 Pages

Case CX160B Schematic Set Excavator Service Manual – 535 Pages

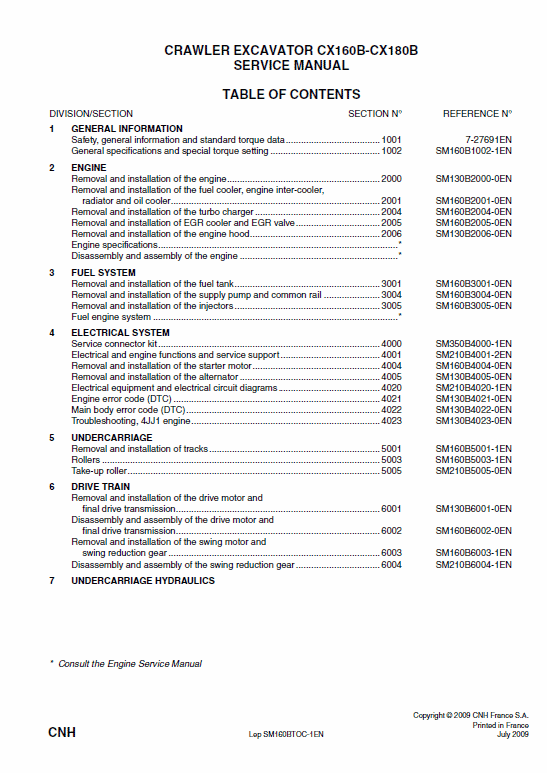

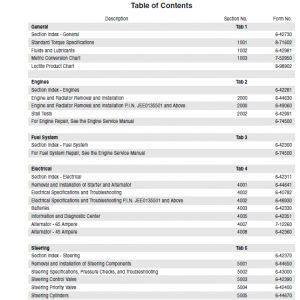

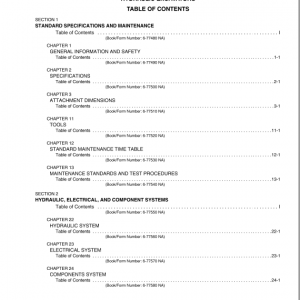

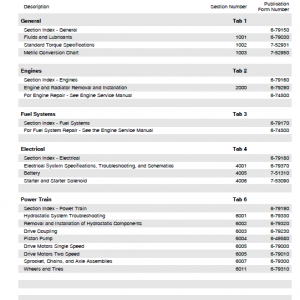

Manual Table of Content:

- General Information

- Engine

- Fuel System

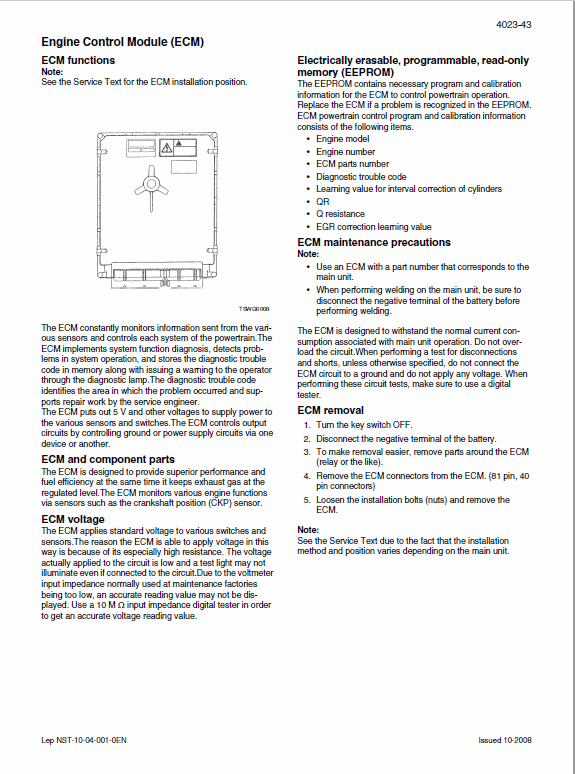

- Electrical System

- Undercarriage

- Drive Train

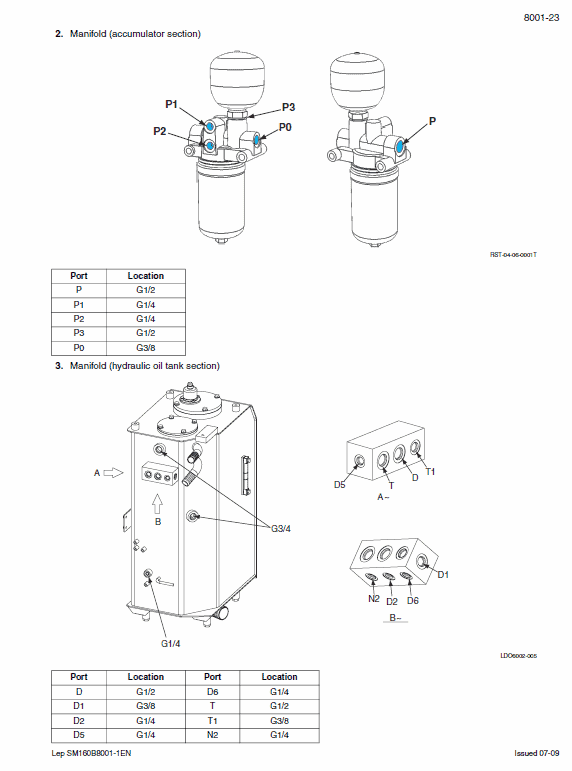

- Undercarriage Hydraulics

- Upperstructure Hydraulics

- Upperstructure

Manual Extract: Flow measurement

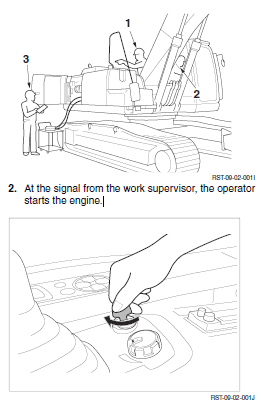

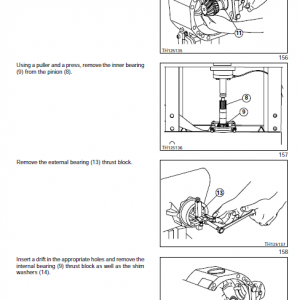

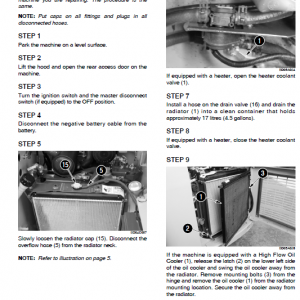

1. When measuring the flow, position the workers as in the figure below.

• Worker 1: Work supervisor, pressure adjustment • Worker 2: Operator

• Worker 3: Flow, pressure measurement, recording

3. Check the hydraulic oil temperature on the monitor (50°C, 122°F). Check that the engine rotation and pump current are normal.

4. The operator signals the arm-out relief operation to worker 1.

5. Worker 2 lowers the arm-out port relief. (Min: 24 MPa (240 bar, 3481 Psi) (P1 + P2)

6. Start of flow measurement.

7. The arm-out relief operation is carried out.

8. Data measured in units of 2.0 MPa (20 bar, 290Psi) (P1 + P2).

• The measurement is carried out from 24.0 to 76.0 MPa (240 to 760 bar, 3481 to 11023 Psi) and ends when the maximum pressure is reached.

9. Remove the flow meters.

• Because from 40 MPa (400 bar, 5802 Psi) the pressure exceeds the permitted value for the flow meter pressure gauge maximum pressure.

10. Reset the arm-in port relief valve to normal pressure.

(For details on this adjustment, see “PRESSURE ADJUSTMENT”.)

11. Remove the pressure gauges etc. and put everything back to normal.

Be the first to review “Case CX160B, CX180B Crawler Excavator Service Manual”

You must be logged in to post a review.

Reviews

There are no reviews yet.